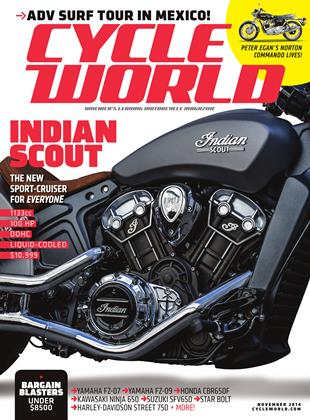

TOOL TIME

WIHA iTORQUE SCREWDRIVER

You know that sickening feeling of a fastener or threads yielding from too much torque? There’s almost nothing worse, especially when you’re reassembling your motorcycle and about to taste beautiful freedom once again.

Great mechanics develop a feel and judgment for fastener tightness by repetition. I have to use torque wrenches.

I’ve got big ones for big stuff and small ones for small stuff, but this Wiha ¡Torque unit (part #28893; $249.98, wihatools.com) is the first screwdriver-type I have tried.

The German-made electronic tool features an LCD window to display inchpounds or Newton-meters and also the number of click cycles. A factory calibration certificate is enclosed; stated accuracy is +/6 percent, and this specific tool deviated less than 2 percent.

The torque range of 9 to 50 inch-pounds

(0.75 to 4.2 foot-pounds) is quite light, so I’ve used the tool primarily for carburetor and magneto work, as well as on lighter case bolts, particularly on vintage stuff where I know the castings are suspect and threads likely worn.

As much as I like using the ¡Torque screwdriver, the real bonus of this set is the bits. A large variety is included: Phillips, Torx, Tri-Wing, Torq-set, square, Allen, and flat blade. They are all nicely made and have proved to fit and grip exceptionally well. There is a quarter-inch socket adaptertoo. Bits are held in the tool with friction, not a magnet.

Although the ¡Torque may be slight overkill for the home mechanic, those of us who don’t work on bikes full time certainly can use the help.

And accuracy is a satisfaction in its own right. -Mark Hoyer

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontThe Golden Cage

November 2014 By Mark Hoyer -

Intake

IntakeIntake

November 2014 -

Ignition

IgnitionBattery Basics

November 2014 By Kevin Cameron -

Ignition

IgnitionThe Kinetic Art of Marc Marquez

November 2014 By Milagro, Tino Martino -

Ignition

IgnitionCw 25 Years Ago November 1989

November 2014 By Mark Hoyer -

Ignition

IgnitionSidi Insider Shoe

November 2014