TDC

Problem Solving

KEVIN CAMERON

WHEN WE LOOK BACK, WE CALL technological change "progress," but it was desperation that forced us to conceive the ideas that would solve specific problems. Engineering does not "progress." It simply moves its problems to higher levels of performance.

I've been looking at the shift from side valves to pushrod-and-rocker overhead valves and then to overhead cams. Engine designers didn't say, "I'm going to leap into the future by inventing ohv!" No one wants to scrap expensive tooling and pay for a new design when present ideas are working well. What causes companies to change is fear of being left for dead by more-agile competitors or discovering that the present design has fatal defects that nickel-and-dime development can't fix.

A side-valve motorcycle won the Senior TT at the Isle of Man for the last time in 1922, thereafter being pushed aside by ohv designs. Why? Let me count the ways:

1) The presence of the hot exhaust port, a part of the cylinder casting, caused increasingly severe cylinder distortion and combustion gas leakage as engine power was pushed higher.

2) The several turns that intake flow had to make—up to the valve, sideways into the valve pocket then 90 degrees down again into the cylinder—seriously restricted flow. This made the almostdirect flow in an ohv very attractive.

3) The extra combustion-chamber surface area resulting from placing the valves in a chamber beside the cylinder increased heat loss, robbing power.

4) The side-mounted valve chamber added volume, making provision of compression ratios over about 6:1 difficult. Yet, by comparison, ohv also had serious problems that made sticking with side valves very attractive:

1) A side valve's cam and tappets were at crankshaft level, easily lubricated by splash. But ohv pushrods and rockers were exposed, so road dust caused them to quickly go out of clearance.

2) A side-valve engine had minimum valve-train mass, allowing it to easily follow cam contours at higher revs. But the extra mass of long pushrods and adequately strong rockers caused premature valve float unless very strong springs were used.

3) Strong springs rapidly stretched the poor exhaust valves, causing them to break. In a side valve, a broken valve head stayed in the chamber, but in an ohv, it was hammered into the piston crown.

4) Building a housing atop the head to enclose the rockers and protect them from dust just made those parts more difficult to lubricate unless the manufacturer was willing to simultaneously adopt a pumped, recirculating oil system. That was too much change in a single step.

Yet ohvs made much better power, luring designers onward. Norton's first-try ohv of 1922, which would become their famous Model 18, was four mph faster than its best side valve. In 1923, all its TT entries would be ohv. When failures handed Douglas the win, Norton hired Walter Moore to fix them. He concentrated on the cycle parts and improving lubrication. For 1925, a recirculating oil system was adopted, using a double-plunger pump. Then, in 1927, Moore took another big step, giving his 500cc CS-1 a single overhead cam.

Why would he do that, rather than perfect the pushrod engine? After all, American pushrod V-Eights run 500 miles at over 9000 rpm in NASCAR racing.

First things first: NASCAR engines are the highest development of the pushrod valvetrain, using sophisticated cam contours to suppress valve-spring oscillations that would otherwise lead to destructive valve float. In 1927, no such thing existed.

And designers did pour effort into pushrod engines. To keep exhaust valves from stretching, they used light springs at the valve and then added helper springs on rockers and pushrods. Even with such measures, TT riders on ohv bikes carried a pair of spare pushrods down one boot and a valve spring depressor down the other. These were long-stroke engines (the Norton was 79 x 100mm, equaling 490cc), so it took a lot of pushrod to reach all the way from tappets in the timing case up to rockers pivoting on stands bolted atop the cylinder head. Even with all those springs, impatient riders constantly floated their valves and sent pushrods clattering down the road.

What it came down to was this: The ohv engine showed it had a lot of potential, but its heavy valvetrain was mechanically incapable of keeping up with the rpm encouraged by its increased gas flow.

English engineers benefited greatly from the "open university" that was Brooklands Speedway. A convenient train ride down from London, Brooklands brought together the best in automobile, motorcycle and aircraft engine design. Racing car engines had been using ohv systems since before 1910 and ohc since WWI. Motorcycles lagged behind. While cars were for the wealthy, motorcycles were general transportation for the masses. To sell, they had to be cheap, which meant they had to be simple.

Then came the Roaring Twenties: Motorcycle makers learned that a win in the TT could triple sales overnight. That made it tempting to develop a potential TT winner even if your factory's bread-andbutter sellers were side-valve sloggers.

The harder they pushed to make a 1920 side valve faster, the harder its problems pinched. Ohv was a step forward in airflow but with new problems of valve float and broken valve heads pounded into piston crowns. Any Brooklands regular, any reader of the copious British motoring press ("the comics"), knew that overhead cam would solve those problems. The lighter valvetrain would need less spring pressure, stretching and breaking hot exhaust valves less often. Yes, pumping oil up to an enclosed cam on the head and recovering it was a royal pain but preferable to outright failure.

Before the 1927 TT, Moore worked around the clock to get two of his new ohc CS-1 engines ready. By the time they were, all the race-week ferries had gone, so Moore had to rent a tugboat to take him across to the Isle of Man. He then had to persuade riders to try them. Stanley Woods and Alec Bennett said yes. Woods lapped at record speed—more than 70 mph—but was out with clutch trouble. Bennett won the Senior race by eight minutes, averaging 68.41 mph.

When you overcome problems, you go faster. But when you go faster, you create new problems. The iron cylinder head and cylinder of the CS-1 were the developed technology of the time. But at the higher level of power the new engine was making, their limited heat conductivity was no longer enough, leading straight to chronic overheating and detonation.

Moore had moved the engine's problems to a higher level of performance.

View Full Issue

View Full Issue

More From This Issue

-

Columns

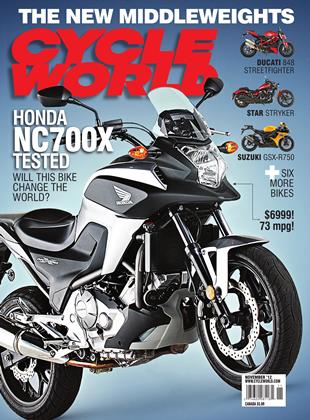

ColumnsUp Front

NOVEMBER 2012 By Mark Hoyer -

Roundup

RoundupNo Quarter Given

NOVEMBER 2012 By Blake Conner -

Roundup

Roundup25 Years Ago November 1987

NOVEMBER 2012 By Blake Conner -

Roundup

RoundupWill the Motorcycle of the Future Come From Pasadena?

NOVEMBER 2012 By Kevin Cameron -

Roundup

Roundup2013 Harley-Davidsons

NOVEMBER 2012 By Paul Dean -

Roundup

RoundupOn the Record:

NOVEMBER 2012 By Matthew Miles