TDC

Friction

KEVIN CAMERON

SOME YEARS AGO, DURING THE 3-liter V-10 era in Formula One, the diameter of crankshaft journals was on its way down—as it also was in World Superbike. This trend was driven by the knowledge that plain-bearing friction rises as the cube of journal diameter. This means that if we compare journals of 30 and 33mm diameters—a mere 10 percent difference—the 33mm bearing will consume one-third more in friction than the 30. All participants in this affair pursued small gains from smaller journals until they broke a few cranks.

Then someone made a wonderful discovery. By going back in the other direction—making cranks and cases more robust—even more friction could be saved, even with larger bearing journals. The conclusion here was that deflection of parts and the resulting concentrations of load were generating the excess friction. This was particularly the case if the engine in question was being used as a stressed element in the chassis.

Ducati, over a period of 23 years, has continuously developed its Ottovalvole (eight-valve) liquid-cooled 90-degree V-Twin. As power has risen from 115 hp to just over 200 in World Superbike racing versions, parts durability has had to keep pace. Cooling has required similar attention in the form of steadily larger water and oil radiators. Crankcase cracking has been a problem since the beginning, requiring many detail improvements and re-homologations of new designs.

There have also been a few problems with cracking of crankpin fillets in crankshafts. In these engines, the two connecting rods share a common crankpin side-by-side, and the crankpin joins the crank webs at either end (this is a one-piece forged crank) in a smooth radius that is rolled to increase the fatigue strength of the material in it by compression. Stress is concentrated at any point in a part at which there is an abrupt change of cross-section, and the crankpin-to-web region is a prime example. Often, the short-term answer to such a problem is to increase the radius of these crankpin fillets and then make room for the larger fillets by slightly narrowing the bearing shells in the connnecting rods.

A possible midterm solution might be to change the material of the part to something that offers greater inherent fatigue resistance, such as one of the vacuum-remelted “VIM/VAR” steels or other higher quality materials. Another approach would be to redesign the part in such a way as to make room for both larger fillet radii and full-width rod bearings.

Yet another method might be to redesign the part to be more robust overall. The father of the Ottovalvole, Massimo Bordi, hoped to take this path by giving the crank much larger mainshafts supported by plain bearings instead of the present large ball bearings. This, he observed, would increase the overlap of the mainshafts with the crankpin, thereby raising the bending stiffness of the entire crank. By reducing flexure and stress at the crankpin-to-web area, this could eliminate cracking.

Engineering is compromise. Money spent to make a production design strong enough for racing is also needed for development of new products. As a concrete example, Norton, in its 1950s certainty that what wins on Sunday sells on Monday, squandered funds that should have been used for the company’s commercial survival. Ducati could not, therefore, drop everything to build a new crank and cases to implement plain main bearings, however desirable they might be.

Fortunately, other tools were available to the Italian factory. Somewhere in the abundant Ducati historical literature is the statement that separate adjustments to the ignition timings of the two cylinders (possible with separate mapping) reduced harmful crankshaft vibration. This is an attractive idea: Modify the source of vibration rather than just crudely make the part thicker and heavier.

Imagine we have instrumented a test motorcycle engine’s crankshaft. We are mainly interested in what CPF’s distinguished European Editor, Bruno dePrato, calls “flapping like Dumbo ears”—the tuning-fork vibration of the crank webs. But we’ll also put toothed wheels on both ends of the crank to check torsional vibration. As the crank spins at moderate rpm, signals from sensors reading these toothed wheels are in step. But as the engine revs up, pulling a load on the dyno, we see the signals rapidly begin to go in and out of phase—the crank is vibrating in torsion. At the same time, we can display any Dumbo-ears motion on another screen. By golly, by making small changes to ignition timing, we can see the crank vibrations vary in amplitude. Neatomosquito! A degree of vibration control right at its source.

On the very interesting website of Doug Lofgren (www.visi.com/~moperfserv/ duc_cams.htm) are lift, velocity and acceleration curves taken from many Ducati desmo cams. What are those dimples I see often but not always at the middle of the profile? Could they be an effort to ease the hard lives of the valveclosing levers? When you hold such a closer in your hands it seems rigid; it’s made of good alloy steel. But high forces at maximum revs turn that lever into a spring. If we just let it vibrate, it will soon die of metal fatigue. So let’s see what we can do to “settle” those vibrations by subtle adjustments to the cam profiles.

As cams, opening and closing levers, and valves vibrate, their motions deviate from the planned ideal, and excess friction appears. During my 2003 visit to Ducati’s headquarters, engineer Claudio Domenicali (father of 1098/1198) said to me, “It may be that a certain change to cam profiles gives an airflow increase sufficient to produce four more horsepower, but on the dynamometer, we may find that the engine in fact makes one horsepower less than before.”

Where did the power go? The new cam forms generated heavier forces, and those forces deflected parts, resulting in friction that ate the power increase. Considering parts as rigid and surfaces as ideal, this should be impossible. But in action, parts “ring” with vibration. Friction between them becomes distinctly non-ideal. Subtle, clever remedies may be required. □

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontThe “last” Rebuild

FEBRUARY 2011 By Mark Hoyer -

Roundup

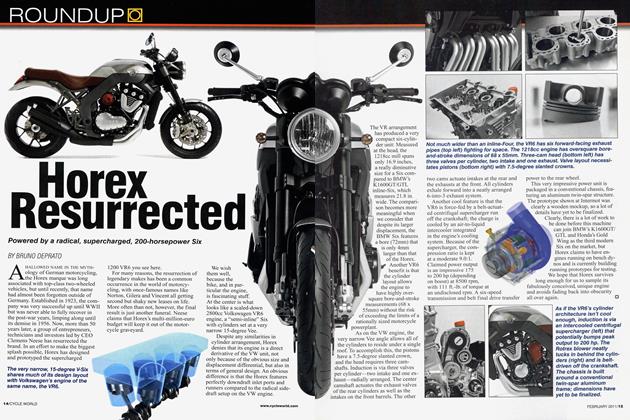

RoundupHorex Resurrected

FEBRUARY 2011 By Bruno Deprato -

Roundup

Roundup2012 Ducati Superbike

FEBRUARY 2011 By Jeff Roberts -

Roundup

RoundupLittle Hauler

FEBRUARY 2011 By Mark Hoyer -

Roundup

Roundup25 Years Ago September 1985

FEBRUARY 2011 By John Burns -

Roundup

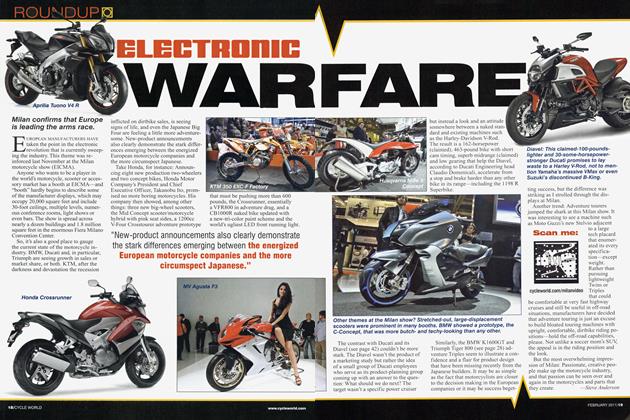

RoundupElectronic War Fare

FEBRUARY 2011 By Steve Anderson