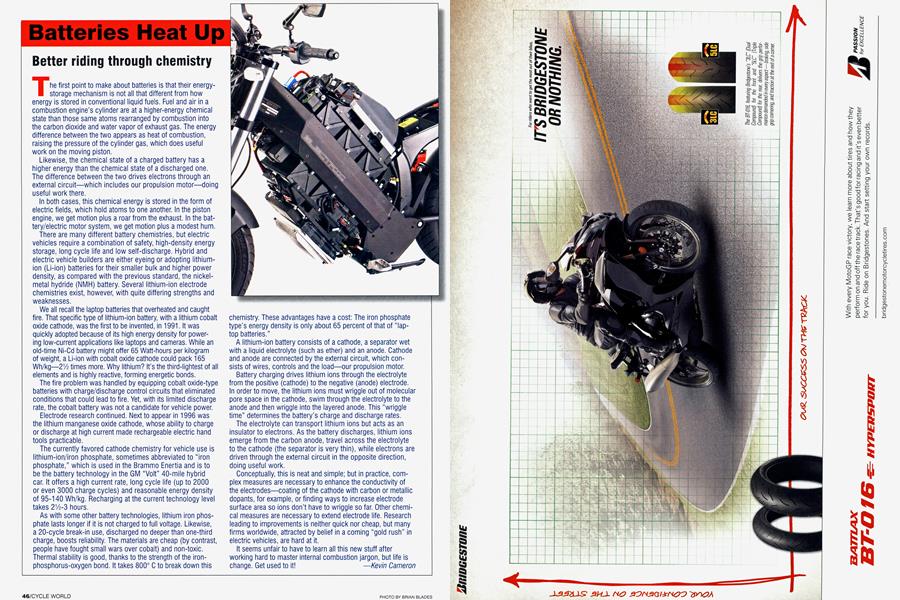

Better riding through chemistry

Batteries Heat Up

The first point to make about batteries is that their energystorage mechanism is not all that different from how energy is stored in conventional liquid fuels. Fuel and air in a combustion engine’s cylinder are at a higher-energy chemical state than those same atoms rearranged by combustion into the carbon dioxide and water vapor of exhaust gas. The energy difference between the two appears as heat of combustion, raising the pressure of the cylinder gas, which does useful work on the moving piston.

Likewise, the chemical state of a charged battery has a higher energy than the chemical state of a discharged one. The difference between the two drives electrons through an external circuit—which includes our propulsion motor—doing useful work there.

In both cases, this chemical energy is stored in the form of electric fields, which hold atoms to one another. In the piston engine, we get motion plus a roar from the exhaust. In the battery/electric motor system, we get motion plus a modest hum.

There are many different battery chemistries, but electric vehicles require a combination of safety, high-density energy storage, long cycle life and low self-discharge. Hybrid and electric vehicle builders are either eyeing or adopting lithiumion (Li-ion) batteries for their smaller bulk and higher power density, as compared with the previous standard, the nickelmetal hydride (NMH) battery. Several lithium-ion electrode chemistries exist, however, with quite differing strengths and weaknesses.

We all recall the laptop batteries that overheated and caught fire. That specific type of lithium-ion battery, with a lithium cobalt oxide cathode, was the first to be invented, in 1991. It was quickly adopted because of its high energy density for powering low-current applications like laptops and cameras. While an old-time Ni-Cd battery might offer 65 Watt-hours per kilogram of weight, a Li-ion with cobalt oxide cathode could pack 165 Wh/kg—21/2 times more. Why lithium? It’s the third-lightest of all elements and is highly reactive, forming energetic bonds.

The fire problem was handled by equipping cobalt oxide-type batteries with charge/discharge control circuits that eliminated conditions that could lead to fire. Yet, with its limited discharge rate, the cobalt battery was not a candidate for vehicle power.

Electrode research continued. Next to appear in 1996 was the lithium manganese oxide cathode, whose ability to charge or discharge at high current made rechargeable electric hand tools practicable.

The currently favored cathode chemistry for vehicle use is lithium-ion/iron phosphate, sometimes abbreviated to “iron phosphate,” which is used in the Brammo Enertia and is to be the battery technology in the GM “Volt” 40-mile hybrid car. It offers a high current rate, long cycle life (up to 2000 or even 3000 charge cycles) and reasonable energy density of 95-140 Wh/kg. Recharging at the current technology level takes 21/2-3 hours.

As with some other battery technologies, lithium iron phosphate lasts longer if it is not charged to full voltage. Likewise, a 20-cycle break-in use, discharged no deeper than one-third charge, boosts reliability. The materials are cheap (by contrast, people have fought small wars over cobalt) and non-toxic. Thermal stability is good, thanks to the strength of the ironphosphorus-oxygen bond. It takes 800° C to break down this chemistry. These advantages have a cost: The iron phosphate type’s energy density is only about 65 percent of that of “laptop batteries.”

A lithium-ion battery consists of a cathode, a separator wet with a liquid electrolyte (such as ether) and an anode. Cathode and anode are connected by the external circuit, which consists of wires, controls and the load—our propulsion motor.

Battery charging drives lithium ions through the electrolyte from the positive (cathode) to the negative (anode) electrode.

In order to move, the lithium ions must wriggle out of molecular pore space in the cathode, swim through the electrolyte to the anode and then wriggle into the layered anode. This “wriggle time” determines the battery’s charge and discharge rates.

The electrolyte can transport lithium ions but acts as an insulator to electrons. As the battery discharges, lithium ions emerge from the carbon anode, travel across the electrolyte to the cathode (the separator is very thin), while electrons are driven through the external circuit in the opposite direction, doing useful work.

Conceptually, this is neat and simple; but in practice, complex measures are necessary to enhance the conductivity of the electrodes—coating of the cathode with carbon or metallic dopants, for example, or finding ways to increase electrode surface area so ions don’t have to wriggle so far. Other chemical measures are necessary to extend electrode life. Research leading to improvements is neither quick nor cheap, but many firms worldwide, attracted by belief in a coming “gold rush” in electric vehicles, are hard at it.

It seems unfair to have to learn all this new stuff after working hard to master internal combustion jargon, but life is change. Get used to it! —Kevin Cameron

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontBike of the Year

April 2010 By Mark Hoyer -

Roundup

RoundupMeet the Motus

April 2010 By Kevin Cameron -

Roundup

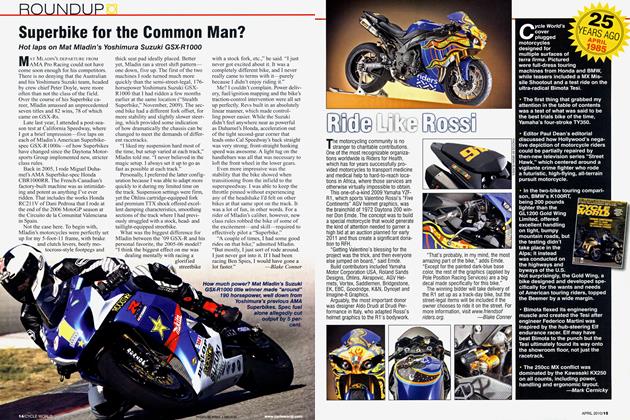

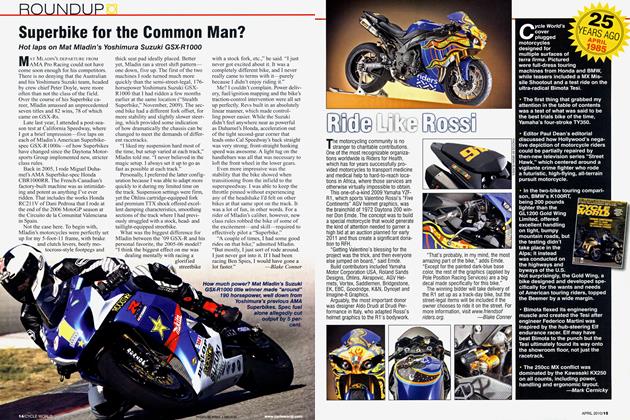

RoundupSuperbike For the Common Man?

April 2010 By Blake Conner -

Roundup

RoundupRide Like Rossi

April 2010 By Blake Conner -

Roundup

Roundup25 Years Ago April 1985

April 2010 By Mark Cernicky -

Roundup

RoundupEtc...

April 2010