SERVICE

PAUL DEAN

Pulling the plug

Q HOW safe is patching or plugging a tire? Is it safe enough to do trackdays? Mark McQueen

Rocklin, California

A Absolutely, positively not; don’t even think about it. Matter of fact, aside from attempting a top-speed run at Bonneville or running flat-out around the NASCAR oval at Daytona, riding at a trackday is about the worst thing you could do with a plugged tire.

Several factors make a plugged tire potentially dangerous. For one, no two tire punctures are exactly the same, so you have no way of knowing if or how badly the tire’s carcass may have been damaged. I’ve seen punctures that look like nothing more than a clean, innocent little hole in the tread; but when the tire was subsequently cut apart and analyzed, quite a few of the cords in the circumferential belts initially had been severed, and even more evidently came apart after the tire was run a short distance at highway speeds. If the tire had been kept in service much longer, it would have suffered a major— and probably sudden—failure.

What’s more, since you don’t know anything about the condition of the hole down below tread level, there is no guarantee that a tire plug will remain in place once the tire is put back into use—especially on a racetrack. Tires run at abnormally high operating temperatures on the track, and that can cause the rubber cement that holds the plug in place to soften and lose some of its grip. Plus, the carcass undergoes considerable flexing as it holds the bike on line in corners, and that can further loosen the plug. Making things even worse is that a tire spends most of its track time spinning at high speeds, so there is considerable centripetal force constantly trying to fling the plug out of the tire. If all of this isn’t a recipe for disaster, I don’t know what is.

Tire manufacturers strongly recommend replacing a plugged tire as soon as possible and that it should never be ridden long distances or at high speeds. Many riders believe that the tire companies say this simply because they want to sell us more tires, but I can assure you that this is not the case. They don’t just manufacture tires, they also test them under all manner of possible conditions, so they know firsthand that riding on a punctured tire is a crapshoot. Yes, the tire may continue to perform flawlessly until it is completely worn out; but if it doesn’t, if it fails suddenly and catastrophically, who do you think stands to lose the most, you or the tire company?

Trackday? Until you spoon on a new tire, fuhgeddaboudit.

Trail guide

QI am considering getting a new bike, so I’ve been studying a lot of specs, and I have to ask: What the heck are rake and trail? Actually,

I think I understand rake, but why do bikes have so many different trail numbers? Dave Fedeler

Columbia, Missouri

A Motorcycles have such varied front-wheel trail dimensions because every model of motorcycle is sufficiently different in its weight, length, weight distribution, center of gravity, engine design and intended use to warrant a front-end geometry best suited to each individual package.

At the risk of oversimplifying what is a relatively complex matter, rake is the need for a fork, given its basic design, to be set at a kicked-out angle (on production bikes, somewhere between the low 20-degree range to the mid-30s) so it can absorb the impact of bumps as effectively as is reasonably possible. The bumps want to push the wheel directly upward, but the motorcycle is moving forward on a horizontal plane; the best solution is a compromise between those two forces—a force “vector,” it’s called—resulting in the rake angles you commonly see.

Trail, meanwhile, provides the selfcentering effect of the front end. In the automotive field, trail is called “caster,” since it acts just like the casters on movable furniture, toolboxes, serving carts and many other common items.

In fact, were it not for rake, the front ends of motorcycles might look a lot more like those casters.

When engineers configure new motorcycles, they use their knowledge, their experience and, in many cases, a sophisticated computer program to decide a starting point for rake and trail. But once that bike gets far enough along in development that it can be ridden, those initial dimensions are altered, often many times, based on the feedback the engineers get from the test riders. Sometimes, even other key elements of the prototype bike—the location of the engine, the positioning of the steering head, the length of the swingarm or the location of the swingarm pivot, to name just a few—might have to be changed when test riders report that no combination of rake and trail is providing the confidence-inspiring “feel” that is so critical to any motorcycle’s performance. When you take into account all those varied and often unpredictable factors, it should be easy to see why trail numbers are inconsistent from one bike to another.

The vapor caper

QI have a bit of a problem with my 2005 Honda XR650L.

When the engine gets hot, it wants to stall when idling. It usually does this at stopsigns and stoplights when I ride on-road, but it does it off-road, too. I’ve tried turning up the idle speed, but then, if I rev the engine, it takes a long time to come down to idle when I let off the throttle and idles way too fast. The engine runs okay otherwise, and until a month ago, it never acted this way in the 6500 miles I’ve put on it since buying it barely used (only 450 miles on the odometer) three years ago. My friend says he thinks the problem is vapor lock. What do you think? Terry Peterson Sunnyvale, California

A Whatever might be wrong with your dual-purpose Honda, it’s almost assuredly not vapor lock. That’s a condition that usually occurs with a system in which the fuel is stored in a remote tank and must first be drawn to the fuel pump via the suction generated by one side of the pump and then delivered to the carburetor by the pressure side of the pump. This is the case with older automobiles that had a carburetor, an engine-driven fuel pump and a gas tank six or eight feet distant at the rear of the vehicle. Vapor lock would occur when engine and/or exhaust heat would cause the fuel in the lines between tank and pump to vaporize. The pumps were able to draw liquid but not vapor, so the engine would stall due to lack of fuel and not restart until the vaporized fuel cooled and returned to liquid form.

Fuel-injection systems have all but eliminated vapor lock because their pumps are located in the fuel tank where they “push” fuel to the injectors rather than pull it. If vapor forms in the lines, the pressure of new fuel entering them drives it out through the injectors, perhaps resulting in a momentary “hiccup” but not a stall.

Largely the same thing happens with gravity-feed fuel systems, such as the one on your carbureted XL-R. The weight of the fuel in the tank thrusting down through the system generally pushes any vapors into the float bowl, where they either return to a liquid state or escape through the vent line.

Instead, I think your Honda’s stalling issues are the result of a lean idle mixture or valves (either intake or exhaust) that have lost all of their clearance. A lean idle mixture could be caused by an air leak at the intake manifold, either at the O-ring that is sandwiched between the manifold and the cylinder head (item #14 in the accompanying parts illustration) or at the rubber carb-mount boot at the rear of the manifold. If you carefully spray a little WD-40 around those two joints while the engine is idling, white smoke exiting the exhaust system would be irrefutable evidence of an intake leak.

If an air leak is not the culprit, your XL-R may have a plugged idle fuel jet in the float bowl. If so, don’t even try to clean that tiny orifice; simply replace the jet, and do so with the next-largest size. To meet emissions requirements, the idle mixture already was lean when the bike rolled off the assembly line, so going up one size would improve the idle in any event.

If neither of those two conditions exists, you’ll then need to check the valve clearances, which should be .004-inch for the intakes and .005 for the exhausts. Even one zero-clearance valve could cause the stalling problem you describe. Just be sure to make this clearance check as soon as possible, because continued running with a tight valve could damage that valve enough to require replacement.

Breaking the mold

QI recently replaced the tires on my ’01 Suzuki SV650 with Bridgestone BT016s, which the dealer suggested as being significantly stickier than the OEM rubber. When I picked up the bike, the installer told me about the residual coating on new tires that the manufacturer uses to help release the rubber from the mold when the tire is made. He warned that the residue makes the tires very slippery for the first 100 miles or so, and that I needed to wear it off naturally by riding carefully, avoiding aggressive lean angles. My questions: 1) Are there no effective methods of removing this coating faster (unnaturally); and 2) how does a rider A Although new tires from some companies, including Bridgestone, are indeed coated with “mold release” that must be worn off before the rubber can provide full grip, that dealership employee’s 100-mile stipulation is misleading. Mileage is not the criteria here; you could ride 100 miles or more on a typical Interstate or open highway, for example, and still have untouched mold release on the sides of the tires. Instead, the best way to remove mold release is to ride at moderate speeds and casual lean angles at first, gradually increasing your speed and amount of lean just a few degrees at a time. This ensures that as you progressively lean farther and farther, the largest part of the contact patch at any time consists of rubber that has already had the mold release scuffed off, thereby providing sufficient grip to prevent the tire from sliding. With this technique, you can prep a new tire for all-out cornering duty in 10 miles or less, depending upon the riding conditions.

wear off the outer surfaces of the tire “naturally” without actually leaning to that angle? Mark Teragawa

Shoreview, Minnesota

A new tire actually provides decent grip before the mold release has been scrubbed off; it just can’t cope with aggressive cornering right out of the box, when the entire contact patch or the greater part of it would be riding on virgin mold release.

I’ve been told of several methods for removing mold release that some riders have tried—wiping the tread with contact cleaner or acetone, or handsanding it with heavy-grit sandpaper. I’ve never tried any of them myself, so I can’t verify their effectiveness or their impact on the rubber. But I have used the gradual-leaning method with every new tire I’ve had mounted, and I’ve never experienced the slightest incident of tire slippage during those “break-in” sessions. □

Got a mechanical or technical problem and can’t find workable solutions in your area? Or are you eager to learn about a certain aspect of motorcycle design and technology? Maybe we can help. If you think we can, either: 1)

Mail a written inquiry, along with your full name, address and phone number, to Cycle World Service, 1499 Monrovia Ave., Newport Beach, CA 92663; 2) fax it to Paul Dean at 949/631-0651; 3) e-mail it to cw1Dean@ aol.conr, or 4) log onto www.cycleworld. com, click on the “Contact Us” button, select “CW Service” and enter your question. Don’t write a 10-page essay, but if you’re looking for help in solving a problem, do provide enough information to permit a reasonable diagnosis. Include your name if you submit the question electronically. And please understand that due to the enormous volume of inquiries we receive, we cannot guarantee a reply to every question.

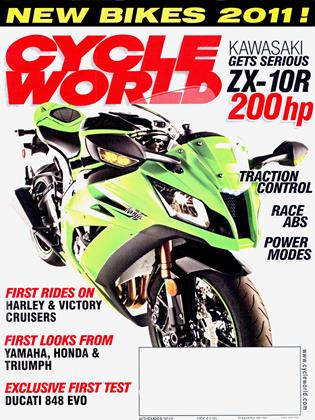

View Full Issue

View Full Issue

More From This Issue

-

Up Front

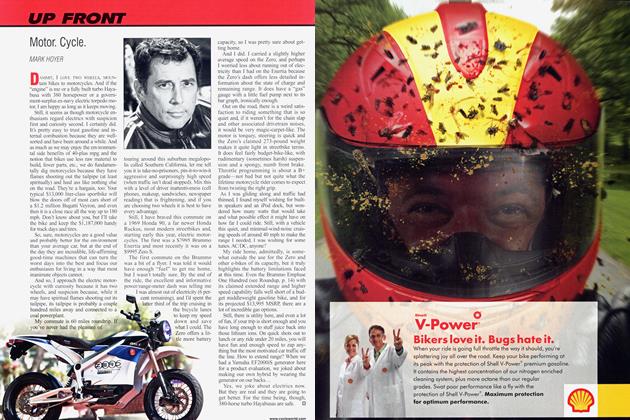

Up FrontMotor. Cycle.

November 2010 By Mark Hoyer -

Roundup

RoundupBuell Fights Back

November 2010 By Steve Anderson -

Roundup

RoundupItalian Triple Threat

November 2010 By Jeff Robert -

Roundup

RoundupUps & Downs

November 2010 -

Roundup

RoundupTeam Cycle World

November 2010 By Paul Dean -

Roundup

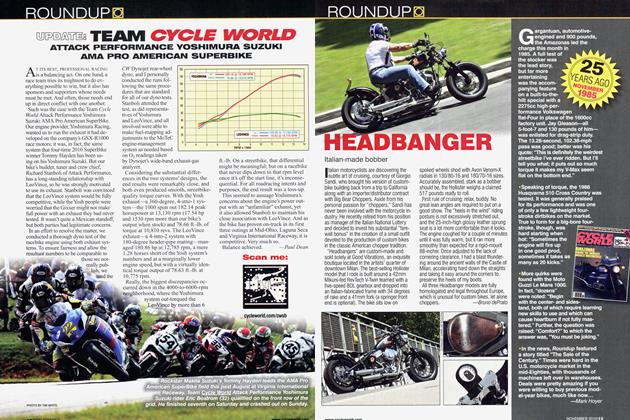

RoundupHeadbanger

November 2010 By Bruno Deprato