SERVICE

PAUL DEAN

Need for (correct) speed

Q Some time ago in a Service letter, a reader inquired about speedometer error. I own a 2006 Yamaha FZ1 on which I have changed the front sprocket, and I know my speedometer is off. It averages somewhere in the range of 100-plus meters for every couple of kilometers traveled. My question is, how do you calculate speedometer error (in kph) for the rest of the world, which is mostly metric? Sheldon Boyden Posted on America Online

A It doesn’t matter whether the units of speed are miles per hour, kilometers per hour, feet per second or furlongs per calendar year; it’s all a matter of percentages. Let’s assume a bike has a 15-tooth front sprocket and a 45-tooth rear. That’s a 3.0:1 ratio (45 + 15 = 3). Then let’s say we switch to a 16tooth front and leave the 45 rear alone. The ratio now is 2.8125 (45 -M6 = 2.8125). That represents a 6.25-percent increase in overall gearing (3.0-2.8125 = 0.1875 is the ratio difference; and so 0.1875 -s3.0 = 0.0625 is the percentage of change). Since this hypothetical sprocket change netted taller gearing between the rear wheel and the transmission (where the speedometer sensor is located), the speedo readings-either mph or kph-would be 6.25-percent lower than they were before the change.

Problem here is that, if your FZ1 is typical, the speedometer already gave incorrect readings before your gearing change. Yamahas are notorious for having optimistic speedometers, often as much as 10 percent, so your new gearing (you didn’t tell me any tooth-count particulars) may have already corrected much of that inaccuracy.

But there’s an easy, $99 solution to such problems: Speedo Tuner (www. speedotuner.com). It’s a little electronic box that plugs into the wiring of an electric speedometer and permits the rider to recalibrate any mph/kph errors that instrument might have. The installation procedure is simple and clearly spelled out in the instructions, and after the recalibration is complete, the box can be permanently mounted out of sight, usually under the seat. Plus, if you decide at some point to switch back to the stock gearing, or if you make another gearing change in the future, or if you replace your bike’s rear tire with one that has a different profile, Speedo Tuner allows you to correct any resultant speedometer errors. Even if all you want is just to correct the OEM speedometer error, Speedo Tuner handles that, as well.

Lashing out

Q Just recently, I checked the valve clearances on my Suzuki SV650, which was at the recommended 15,000mile point. I found all the valves to be within spec, but they all were close to the small end of the tolerance. The correct intake spec is .004to .008-inch, and one intake was at .005 and the others were a “loose” .004. The same with the exhausts: Their spec is .008to .012-inch, and they all were at .009. The next scheduled valve inspection would be at 30,000 miles. Since everything is near the lower limit of the spec, would it be prudent to check the valves earlier? The underlying question is, do these shim-under-bucket tappets normally increase or decrease clearance as the engine wears? Dave Isacco Chardon, Ohio

A Most of the time, valve clearances-also sometimes referred to as valve lash-tend to decrease slightly as an engine racks up hours. The constant impact of the valves closing against their seats gradually hammers enough of a shallow indentation around the contact area of the valve heads to make the valve sit a thousandth or so higher in the head, reducing the clearance. During the 15,000 miles you have ridden your SV650, each valve has made closing contact with its seat somewhere in the neighborhood of 50 million times, perhaps even more depending upon your use of the five lower gears. In an engine that is raced or ridden at high rpm for long periods, the number of closing impacts can be several times greater within the same mileage period, so their clearances are likely to change even more quickly.

Sometimes, though, valve lash will increase. This usually is caused by wear of the valve-train component that the lobe pushes against-shim bucket, rocker arm, other types of cam followers, etc.

In your case, the valve-lash measurements you gathered really don’t tell the whole story. This was the first time you checked the SV’s valves, so you don’t know what their clearances were in the first place. The engine could have been assembled at the factory with clearances at the tight end of the acceptable range, and those settings have changed very little since. What’s more, even when valve settings do change, they don’t necessarily do so at a linear rate. The clearances usually tighten up the most during breakin as the valves and seats conform to one another. After that, changes tend to occur at a slower rate. I know of quite a few motorcycle engines that have gone 50,000 miles or more between valve adjustments.

If you truly are concerned about your Suzuki’s valve clearances, your best option is to check them again in another, say, 5000 miles. That is much sooner than the next prescribed interval at 30,000 miles. That way, if the clearances are shrinking fast, you could correct them before they became too tight. You would also be able to detect a wear trend by comparing those clearances with the ones you measured at 15,000 miles.

Chain slack for dummies

Q I feel kind of stupid asking what you probably think are dumb questions, but I’ll ask anyway: First, why does a bike’s drive chain change its slack so much as the rear wheel moves up and down? Second, because the chain slack does change, how do you know where to adjust the chain and how much slack to give it? I know, you’re rolling on the floor laughing at me right now, but after you calm down and regain your composure, I would really appreciate an answer. Craig Knapp Mesa, Arizona

A No side-splitting, knee-slapping guffaws here, Craig; in my opinion, the only dumb questions are the ones that never get asked.

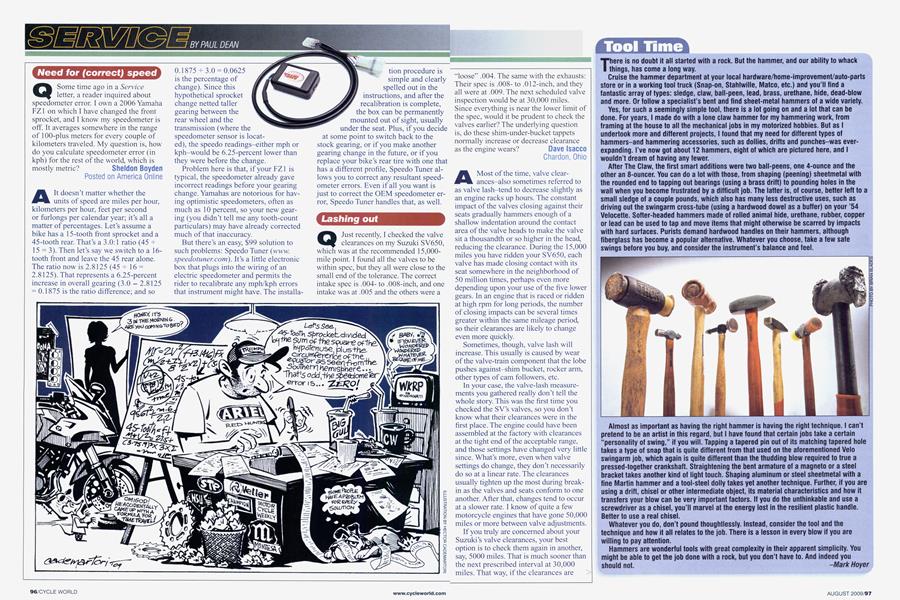

A drive chain’s slack changes with rearsuspension movement simply because the chain and the swingarm are working on two different radii. The rear sprocket and the rear-wheel axle are concentric, so they move together and swing in the same arc at the rear of the swingarm. The countershaft sprocket, however, is located ahead of the swingarm pivot, so the entire chain-andsprockets assembly works on a longer radius than the swingarm-and-rear-axle assembly. As depicted in the accompanying illustration, the chain is its tightest when the axle, the swingarm pivot and the countershaft all are on the same centerline, which places the rear sprocket most distant from the countershaft sprocket; but any time those three shafts are not in perfect alignment, the chain slack increases because the radii differential has caused the rear sprocket to move slightly closer to the countershaft sprocket.

Over the years, a scant few motorcycle designers have attempted to remedy this problem by placing the countershaft concentric with the swingarm pivot. That allows both the chain and the swingarm to work on the same radius, so chain tension remains constant throughout the entire arc of rear-suspension travel. The most recent (and only current) motorcycle to employ this concept is BMW’s new G450X enduro.

As far as proper chain adjustment is concerned, the procedure varies some> what depending upon individual makes and models. Ideally, the chain should be checked and adjusted where the slack is the least; this generally is in the middle of the chain’s lower run and with the countershaft, swingarm pivot and rear axle all on the same centerline. But that is not practical on all bikes, especially some of those with long-travel suspensions and/ or extreme downward swingarm angles that prevent the easy alignment of those three axes. This is why it is best to follow the chain-adjustment procedures outlined in each bike’s owner’s manual.

Torquey or dorky?

Q I have a neighbor who’s kind of a dweeb. He rides a BMW R1200 that he fusses over all the time, and he’s a fanatic about using a very expensive electronic torque wrench to tighten every single nut and bolt on his bike and even on his BMW car. I do all the repairs and maintenance on my Suzuki 1000 VStrom that has 55,000 miles on it, and I’ve not had a bolt or nut or any other part break or fall off. I’ve never used a torque wrench on the bike, and in fact I don’t even own a torque wrench. Is my neighbor guilty of overkill or am I guilty of underkill? Chris Greene Irondequoit, New York

A Underkill, eh? That’s a new one on me. But this question is not; I’ve been asked it before. And given a choice between your neighbor’s style of maintenance and yours, I’d definitely go with his. He might be a bit of a fanatic, but there is nothing wrong and a whole lot right about torquing every nut and bolt to its prescribed specification. Otherwise, how do you know if the threads on some of those fasteners have been stretched close to the point of failure? What assurance do you have that a component isn’t being distorted by threaded fasteners that are too tight? Or that some part is right on the verge of falling off but just hasn’t yet done so? More to the point, what makes you think your gut-feeling tightening techniques are superior to those that involve precise torquing to a specification carefully determined by the strength rating of your bike’s fasteners and the engineering prowess of the people who built the motorcycle? Okay, nothing so far has fallen off' your V-Strom, but that could be due more to good luck than anything else. If so, I hope your luck holds out. But if you come up with any more interesting new words, please pass them along.

Got a mechanical or technical problem with your beloved ride? Can’t seem to find workable solutions in your area? Or are you eager to learn about a certain aspect of motorcycle design and technology? Maybe we can help. If you think we can, either: 1) Mail a written inquiry, along with your full name, address and phone number, to Cycle World Service, 1499 Monrovia Ave., Newport Beach, CA 92663; 2) fax it to Paul Dean at 949/6310651; 3) e-mail it to CW1Dean@aol.com; or 4) log onto www.cycleworld.com, click on the “Contact Us” button, select “CW Service” and enter your question. Don’t write a 10page essay, but if you’re looking for help in solving a problem, do include enough information to permit a reasonable diagnosis. And please understand that due to the enormous volume of inquiries we receive, we cannot guarantee a reply to every question.

View Full Issue

View Full Issue

More From This Issue

-

Up Front

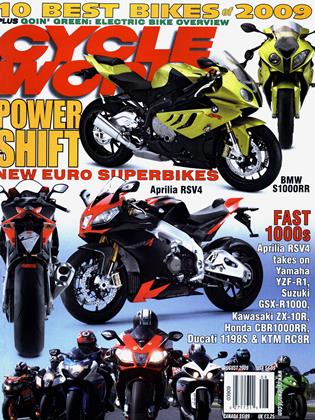

Up FrontTen Rest, 2009

August 2009 By David Edwards -

Leanings

LeaningsA Guy of the Moment

August 2009 By Peter Egan -

TDC

TDCInstruments of Control

August 2009 By Kevin Cameron -

Departments

DepartmentsHotshots

August 2009 -

Roundup

RoundupElectric Arrival

August 2009 By Kevin Cameron -

Roundup

Roundup25 Years Ago August 1984

August 2009 By Paul Dean