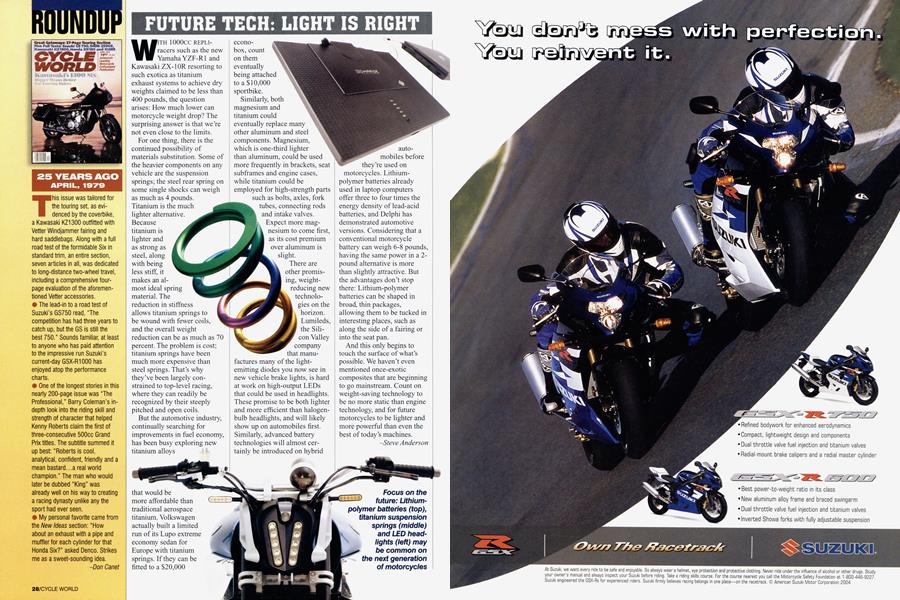

FUTURE TECH: LIGHT IS RIGHT

WITH 1000cc REPLIracers such as the new Yamaha YZF-R1 and Kawasaki ZX-10R resorting to such exotica as titanium exhaust systems to achieve dry weights claimed to be less than 400 pounds, the question arises: How much lower can motorcycle weight drop? The surprising answer is that we're not even close to the limits.

For one thing, there is the continued possibility of materials substitution. Some of the heavier components on any vehicle are the suspension springs; the steel rear spring on some single shocks can weigh as much as 4 pounds. Titanium is the much lighter alternative. Because titanium is lighter and as strong as steel, along with being less stiff, it makes an almost ideal spring material. The reduction in stiffness allows titanium springs to be wound with fewer coils, and the overall weight reduction can be as much as 70 percent. The problem is cost; titanium springs have been much more expensive than steel springs. That’s why they’ve been largely constrained to top-level racing, where they can readily be recognized by their steeply pitched and open coils.

But the automotive industry, continually searching for improvements in fuel economy, has been busy exploring new titanium alloys that would be more affordable than traditional aerospace titanium. Volkswagen actually built a limited run of its Lupo extreme economy sedan for Europe with titanium springs. If they can be fitted to a $20,000 econobox, count on them eventually being attached to a $10,000 sportbike.

Similarly, both magnesium and titanium could eventually replace many other aluminum and steel components. Magnesium, which is one-third lighter than aluminum, could be used more frequently in brackets, seat subframes and engine cases, while titanium could be employed for high-strength parts such as bolts, axles, fork tubes, connecting rods and intake valves. Expect more magnesium to come first, as its cost premium over aluminum is slight.

There are other promising, weightreducing new technologies on the horizon. Lumileds, the Silicon Valley company that manufactures many of the lightemitting diodes you now see in new vehicle brake lights, is hard at work on high-output LEDs that could be used in headlights. These promise to be both lighter and more efficient than halogenbulb headlights, and will likely show up on automobiles first. Similarly, advanced battery technologies will almost certainly be introduced on hybrid automobiles before they’re used on motorcycles. Lithiumpolymer batteries already used in laptop computers offer three to four times the energy density of lead-acid batteries, and Delphi has demonstrated automotive versions. Considering that a conventional motorcycle battery can weigh 6-8 pounds, having the same power in a 2pound alternative is more than slightly attractive. But the advantages don’t stop there: Lithium-polymer batteries can be shaped in broad, thin packages, allowing them to be tucked in interesting places, such as along the side of a fairing or into the seat pan.

And this only begins to touch the surface of what’s possible. We haven’t even mentioned once-exotic composites that are beginning to go mainstream. Count on weight-saving technology to be no more static than engine technology, and for future motorcycles to be lighter and more powerful than even the best of today’s machines.

-Steve Anderson

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontArt of the Chopper

April 2004 By David Edwards -

Leanings

LeaningsThe Age of Tough Engines

April 2004 By Peter Egan -

TDC

TDCCutting It Close

April 2004 By Kevin Cameron -

Departments

DepartmentsHotshots

April 2004 -

Roundup

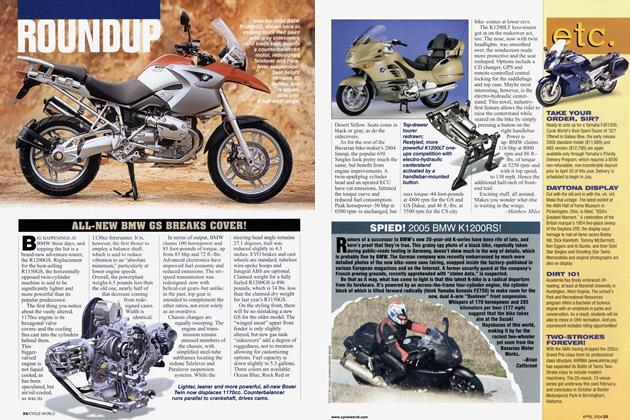

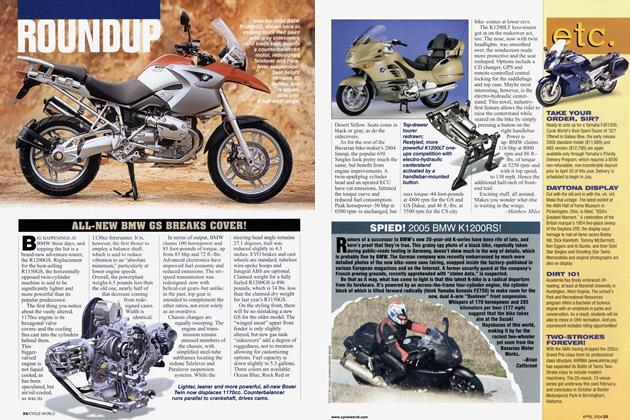

RoundupAll-New Bmw Gs Breaks Cover!

April 2004 By Matthew Miles -

Roundup

RoundupSpied! 2005 Bmw K1200rs!

April 2004 By Brian Catterson