SERVICE

Nitwits and fairy tales

Paul Dean

In the May, 2002, Service, you answered a letter ("Wheeler or dealer?") from a reader who was upset with derogatory comments you've often made about motorcycle dealers. Your reply was good, but why not be fair and ask dealers to write and tell about all the schemes, lies and outrageous tricks that some of their customers have tried to pull? That could be very educational for all those nitwits who actually think anyone believes that their bike blew all four pistons through the head while idling in the church parking lot on Sunday. I'll bet you'd get some doozies. I'm not a dealer, but I've stood at parts counters and heard customers tell some of the most absurd stories you could possibly imagine, and do it straight-faced. I've often wondered how often dealers would like to tell these idiots to get lost because they know those people are lying through their teeth. Phil Ford Posted on www.cycleworld.com

Your letter makes a good point, but I hope you `re not suggesting that the be havior of a few imbeciles gives dealers a valid excuse to treat other customers poorly. Yes, many customers do tell their

dealers incredible fai,y tales that no one in their right mind would believe. But that's not justification for dealers behaving in a like manner and telling outright lies or giving misleading infor mation to customers who have legiti mate problems. The situations and chal lenges are no d~fjerent for motorcycle

dealers than they are for any other busi ness that has to deal with the public. Our 33rd president, Harry S. Truman, once said, "If you can `t stand the heat, get out of the kitchen." Same goes for motorcycle dealers: If they can `t cope with the realities of being in a retail business, they should get out of it.

Suzuki's 562cc Triple

lOWn a 1 996 Suzuki GSX-R75'O that runs fine in weather above 35 degrees, but in colder temperatures, the outside left cylinder doesn't fire. I really enjoy cool Wisconsin early spring and late fall rid ing. What can I do? Heath Stumpf Appleton, Wisconsin

Thefirst order of business is to determine if the problem is electrical or fuel-related. Start by swapping the sparkplug wires for the two outside cylinders, both of which are fired by the same coil. If the other outside cylinder then won `t run when the engine is cold, you `ii know that the problem is either the coil or the sparkplug wire. If the prob lem remains in the same cylinder~ swap its sparkplug with the one from the other out side cylinder If the problem also changes sides, you `ii know that the culprit is the sparkplug. If it doesn `4 you `11 need to look elsewhere. But while you `re still in plug swapping mode, take the opportunity to perform a rudimentary compression check to determine if the suspect cylinder has compression when cold.

If your trip down the plug/coil/com pression road proves to be a dead-end, turn your attention to the carburetors. First, pull the cold-start enrichener

(choke) knob open and observe the ac tion of the dead cylinder's enrichener plunger; it should open just as far and at the same time as the other three. If it does not, that is likely the problem. If the chokes are all synchronized, however, disassemble that cylinder's enrichener to ensure that none of its internal passages are blocked. If that checks out okay, drop the float bowl on that carb and unscrew the main jet and pilot jet. Check them for blockage, and blow them out with high-pressure air if you suspect that their orifices are not completely clear of debris. Also, turn the petcock on while the float bowl is removed and see iffuel flows freely past the float needle.

If you perform all these troubleshoot ing checks, the chances are very good that one of them will turn up the cause of that outside cylinder's reluctance to run when cold.

Vulcan tap-dance

Last April, I puichased a 1995 Vulcan 88 with 3400 miles on it. When I first start the engine with the choke on at fast idle, it runs quietly. But when it idles down, I hear a ticking in the motor that goes up and down with changes in rpm. Once the bike runs for 15 minutes or so, the noise

quiets down quite a lot but not entirely. Could it be a wristpin or maybe a bear ing? Is it something I should worry about? Other than that, I love the bike. John Cody Woodstock Valley, Connecticut

It s' practically impossible for me to trou bleshoot engine noises without actually hearing them; the ability to detect very subtle differences in the tone and fre quencies of various noises is pivotal in diagnosing their cause. But f your de scription of the noise as a "tick" is accu rate, your Vulcan probably doesn `t have a bad bearing; that noise would be more like a heavy knock than a tick. It's also unlikely that a loose wristpin is the cul prit; that noise would be a lighter, high er-frequency knock but still not a tick.

It~my guess, then, that your Vulcan has a sticky hydraulic valve-lash ad juster. Just as many car engines and all overheadvalve Harley-Davidsons have self-adjusting hydraulic tappets, the Vul can has a similar little hydraulic device on the end of each rocker arm, right where the rocker contacts the valve stem. When they work properly, these adjusters automatically maintain zero valve lash, which is why you never have to adjust the valves. But the Vulcan `s adjusters are very small and simplistic, and even a tiny speck of dirt or a faulty ball-check in one of them can allow it to malfunc tion, causing a ticking noise every time that valve is opened.

Kawasaki has a recommended proce dure for checking and bleeding these hydraulic adjusters, but it's too complex to describe here, especially without the aid of photographs or drawings. Plus, gaining access to the rockers requires extracting the engine from the frame, since there is insufficient clearance above the engine to permit removal of the rocker boxes. Should you attempt this repair on your own, the procedure for checking and replacing the ad justers is detailed in the Vulcan 1500 shop manual. But I recommend that you either let a dealer handle the work or, since the bike seems to run okay, just let it go and see if it gets worse or maybe goes away after a couple offrequent oil changes. If the noise is a hydraulic ad juster, its complete failure will not cause any engine damage; the engine will just run poorly and more noisily.

Size does matter

I have a `75 Norton Commando that de veloped some corrosion in the frontbrake master-cylinder bore. This was, for all practical purposes, Norton's last year, and the `75 front brake is unique to that year, making replacements hard to come by. I elected to have the master cylinder resleeved, but I am told that this has required a slightly smaller-di ameter piston. Supposedly, this yields better brake feel and response, due to the smaller master cylinder, but the gearhead in me wants to know the details. I've read Kevin Cameron's "Brakes" chapter in his excellent Sportbike Performance Handbook several times, but I am still a bit confused by the formulas involved. I am trying to write an article about this for our Norton owners' newsletter, so any assistance will help me appear less ignorant to this very tough crowd. Dean Baker Posted on www.cycleworld.com

I'll try to make this easy. Using hypo thetical dimensions, let's suppose the point at which the rider applies pres sure to the front brake lever is 4 inches from the lever's pivot, and that the dis tance between the pivot and the plunger that pushes the master-cylinder piston is 1 inch. This gives the lever a 4-to-i "leverage ratio." So, f the rider applies 10 pounds offorce on the lever the re sultant force applied to the master-

cylinder piston will be 40 pounds. One of the principles of hydraulics

stipulates that in a closed hydraulic sys tem (which a braking system is), pres sure applied at any point (such as at the master cylinder) is the same throughout the entire system (including at the brakecaliper pistons). So, if the surface area of the master-cylinder piston is 0.5square inch, and it is being pushed with aforce of 40 pounds, the braking system is under a pressure of 80 pounds per square inch (40 ± 0.5). If the surface area of each caliper piston is 2 square inches (four times that of the mastercylinder piston), the total force exerted by each caliper piston on the disc will also be four times greater, or 320 pounds. If the caliper has four pistons, the total braking force of that caliper would be 1280 pounds (320 x 4).

A smaller master-cylinder piston al lows the rider to generate more braking force at the calipers. If for example, the area of the master-cylinder piston were reduced from 0.5 to 0.4 inches but all the other brake-system components re mained the same, the resultant hydraulic line pressure would increase from 80 to 100 psi (40 ± 0.4). But because a cer tain volume of brake fluid in the system must be displaced to move the caliper pistons from their at-rest position and push them against the rotor surfaces, a smaller master-cylinder piston requires a greater movement of the hand lever to move that volume offluid and thus acti vate the brakes.

The bottom line? I don `t know how much smaller your Norton `s master cylinder bore is now than it was before, but f the difference is more than trivial, you `11 probably notice that the brakes seem a little more powerful and that the lever must be moved slightly farther to engage them.

Tighten y'our belt

I h~ie a 2001H-D Road King with just 1800 miles. At the first service (1000 miles), one of the check items was the fi nal-drive belt tension, which the dealer said was okay. I recently checked the ten sion and found that the belt moves from top to bottom approximately 1½ inches. When I called the dealer and told him this, he said that an inch-and-a-half is the nor mal freeplay with a rider off the bike, and that it should be about 1 inch with a rider on. I went back and checked it again and found that the freeplay was almost the same either way. I then called Harley's customer service, and they said the belt should be taut and only move up or down about `/8-inch under load. Who is right? Also, what is the correct torque setting for the rear axle? Warren Lessing Posted on www.cycleworld.com

FEEDBACK LOOP

In reference to your response to Earl Plummer ("Yellow speedo thingo") in the April issue in regard to speedometer recalibrators, I've been using a model from a company called Autolrans Inc. (~wvwautotransinc.com/RecaI.htm) on my 2000 Honda RC51 for about a year and a half now. It's very precise and compact, and is adjustable to less than a 1 mph error. It's designed for cars, but also comes in a version that can be spliced into a wi~ng harness, which is what I used. Installation took me less than an hour, and the unit can be recalibrated from between minus 31 percent and plus 31 percent. Jim Hanus Richmond, Michigan

Thank you so much, Jim. When I published that letter I was hoping some know ledgeable gearheads out there would inform us ofproducts or systems they had used to compensate for speedometer error after a gearing change. The solution you de scribe is, of course, only applicable to electronic speedometers. Nevertheless, I'm sure Mr~ Plummer and countless other Cycle World readers who have faced this same dilemma are grateful for your input.

According to Harley-Davidson `s own factory shop manuals, both the dealer and the customer-service representative were wrong. The manuals say that the belt should have between /16and 3/8-inch freeplay, measured midway between both pulleys with the rider on the seat and 10 pounds ofpressure applied to the belt. The transmission should be in neu tral, of course, to eliminate any driveline load that could affect belt tension. Harley makes a special toolfor applying that 10 pounds of pressure on the belt, but most competent Harley mechanics have developed a good feel for the right amount of tension. If the belt is too tight, it could break; if it's too loose, it could jump on the pulleys.

The correct torque specification for the rear axle is 60 to 65 foot-pounds.

Motor music

Okay, here's one for you: Why do engines with a different number of cylinders or dif ferent cylinder arrangements not sound alike? For example, why does a V-Twin not sound like a parallel-Twin? Why does a 45-degree V-Twin have an entirely differ ent exhaust sound than a 90-degree V-Twin or a BMW opposed-Twin? Why does a Four sound different than a Triple or Twin? All the events that take place in the cylin ders are the same (intake, compression, combustion, exhaust) no matter how many cylinders an engine has or how they are arranged, but all these different engines have considerably different exhaust sounds. My friends and I have asked nu merous individuals in our circle of motor cycling acquaintances, including a few race tuners, and have yet to receive a plau sible explanation. Tom Baihaus Ravenna, Ohio

You might not get one from me, either. This is an extraordinarily complex sub ject that difficult to understand because a person can `t "see" most of the factors that determine the character of an en gine `s sound. I'm not an expert in the field, and even f I were, I would need considerably more space than is avail able here to provide a thorough dis course on the dynamics of sound.

But I can offer a simplistic explanation that should at least get you pointed in the right direction. The d~f/erences in engine sounds are largely dictated by the differ ences in the way the sound waves of com bustion interact with one another according to the number and configura tion of cylinders. When waves of any given frequency are in phase with others of the same basic frequency, they tend to amplify one another; when they are out of phase, they tend to cancel one another. And that phasing is very dependent upon several factors, including the configura tion of the engine and the firing intervals of its cylinders.

An engine configuration that tends to cancel high frequencies and amp4fy low frequencies will likely have a deeper ex haust note. Conversely, an engine design that cancels many of the lower frequen cies and ampl~fles many of the higher ones will probably have a higher-pitched exhaust note.

Two key factors are the degrees of en gine rotation between firing intervals, and whether or not those intervals are even or uneven. An inline-Four, for in stance, fires evenly, every 180 degrees; a parallel-Twin with a 360-degree crankshaft also fires evenly, every 360 degrees. Yet a 360-degree Twin has an entirely different sound than an inline Four. It also has a different sound than a 180-degree parallel-Twin, which fires at uneven, 180/540-degree intervals. A Harley-Davidson 45-degree V-Twin, which fires at 315/405-degree intervals, sounds nothing like either of the paral lel-Twins. A 90-degree Ducati V-Twin, which fires at 270/450-degree intervals, sounds more d~fferent yet. D~fferences in the interaction of the sound waves ema nating from these cylinder combinations are primarily what give them differing exhaust notes.

Numerous other factors also can af fect an engine's sound, such as cam timing, compression ratio, displace ment, operating rpm range, etc., but one of the more influential is the ex haust system. A perfect example of an exhaust system effect on sound can be heard-even on television-at NA SCAR races. On shortand inter mediate-length tracks, most of the cars use two separate, unconnected 4-into1 exhaust systems, one per cylinder bank; on the big tracks, they use es sentially the same configuration but with a siamese connection under the car that intermingles the sound waves of all eight cylinders before branching out into two separate outlets. Other wise, the engines are mostly identical. On shorter tracks, the cars have a typ ical deep, soulful V-Eight bellow; on longer tracks, they sound entirely d~f ferent, with a high-pitched wail that belies the fact that they are big-inch American V-Eights.

NASCAR tuners don't do this for the sound; they do it for performance. Sound waves are a vital tuning vari able, and the engine builders use differ ent exhaust configurations to achieve spec~flc power characteristics that suit the track in question.

Will a can-opener work?

In the April, 2000, issue, you answered an inquiry ("Ferrous Bueller") from a Buell owner who had cut open his Cy clone's oil filter and found some metal fil ings that stuck to a magnet. My question is, how did he get the filter element out of the steel housing? If he used a hacksaw or a grinding wheel, some of the ferrous material he found in there could have been filings created by cuffing the outer housing. If not, how did he get the filter apart? Stan Atwell Posted on America Online

He used a special cutter designed specifically for that purpose. It's kind of an oversized tubing cutter that fits over the open end of the filter and uses a sharp cutting wheel to slice cleanly through the metal outer case. You just adjust the depth of the cutting wheel to continue piercing the metal as you ro tate the tool around the circumference of the filter, and once the case is complete ly cut, you lift the top and the attached filter element up and out.

Inspecting oil-filter elements is a post race practice followed religiously by most automobile and many motorcycle race teams in an attempt to detect inter nal engine problems before the motor self-destructs. The filter cutters cost be tween $40 and $80, depending upon the manufacturer, and are available from numerous race-supply retail and cata log outlets.

The Duke of Earles

Do you know why BMW opped using the Earles-type front fork on its motorcy cles in the late 1960s? I have asked this of many people over the years and no one has ever given me an answer. Robert Kemske Posted on www.cycleworid.com

This is a question that would be best asked of BM~ but you might have a hard time finding anyone there who was involved in that decision and is still ac tive in the company. The Earles fork was used on production BMWs between 1955 and 1969, and it's my somewhat educated guess that the switch to con ventional telescopic forks was made for several reasons: they're lighter, cheap er to manufacture and, for the task at hand, no less functional than Earles forks. Back in that era, sidecars were extremely popular in many parts of the

world, for both road use and racing, and the Earles fork is especially able to cope with the tremendous side loads placed on the front suspension when the front wheel has to make the vehicle turn without leaning. As sidecars gradually faded into relative obscurity, the need for such lateral rigidity was greatly re duced, and conventional forks began to make more sense for the exigencies of the market. At least, that's my story and I'm stickin `to it.

Affair with a stud

I have a serious problem with my `99 Buell M2. One of the studs that holds the header pipe in the front cylinder has snapped off

slightly below the surface of the head. What are my options? jimijamesgee Posted on www.cycleworld.com

The remaining piece of the stud can be extracted, but it's not an easy or fail-safe job. And while it may be possible to re move the stud with the head still on the engine and the engine still in the frame, the task is much easier and less likely to go awry fyou remove the head and work with it on a bench.

JIMS Machining makes a special tool, called the Exhaust Stud Drill Plate (part #1705), intended just for this repair~ It's a thick plate that mounts over the ex haust port using the remaining stud, and at the opposite end of the plate, directly in line with the other stud hole, is a drill guide that allows you to bore straight through the exact center of the broken stud. The tool also includes a ¼-inch drill bit, which is the size needed to cut away all of the broken stud, right down to the tops of the threads in the head. The final step is to run a tap through the threads to clean out any remaining pieces of the stud.

This is not ajob that a rookie mechan ic should attempt. It's all too easy to mu tilate the stud hole enough to require further drilling and the insertion of a helicoil. Actually, you could screw it up so badly that you would need to have the hole welded up and then redrilled and tapped. If possible, you should turn the job over to someone who has experience with such repairs.

Since you `re not a practicing Harley mechanic, the $86 price of the Exhaust Stud Drill Plate is a lot of money for a tool you `11 probably never use again. But if you want to buy one anyway, you'll have to order it through a dealer or other motorcycle shop; JIMS is not a re tail seller~

Got a mechanical or technical problem with your beloved ride? Can't seem to find reason able solutions in your area? Maybe we can help. If you think we can, either: 1) Mail your in quiry, along with your full name, address and phone number, to Cycle World Service, 1499 Monrovia Ave., Newport Beach, CA 92663; 2) fax it to Paul Dean at 949/631-0651; 3) e-mail it to CWlOean@aol.com; or 4) log onto www.cycleworld.com and click on the Feed back button. Please, always include your name, city and state of residence. Don't write a 10page essay, but do include enough information about the problem to permit a rational diagno sis. And please understand that due to the enor mous volume of inquiries we receive, we can't guarantee a reply to every question.

View Full Issue

View Full Issue

More From This Issue

-

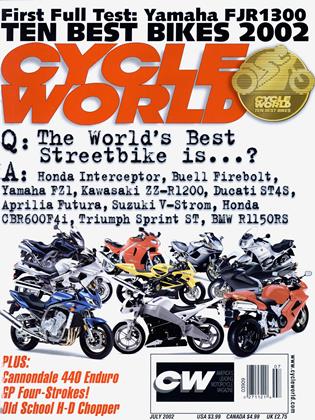

Up Front

Up FrontTen Rest, 2002

July 2002 By David Edwards -

Leanings

LeaningsGreat Mysteries of Motorcycling

July 2002 By Peter Egan -

TDC

TDCDetails of Drag

July 2002 By Kevin Cameron -

Departments

DepartmentsHotshots

July 2002 -

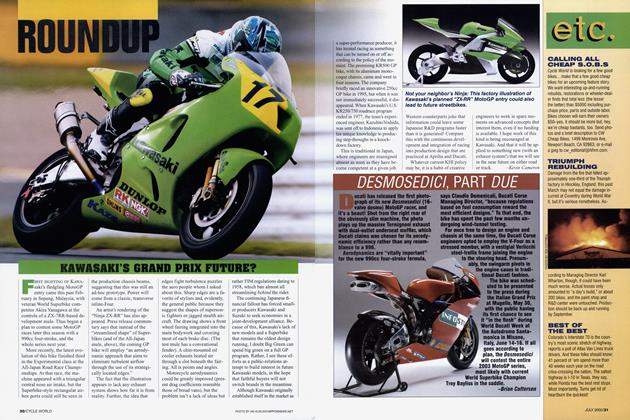

Roundup

RoundupKawasaki's Grand Prix Future?

July 2002 By Kevin Cameron -

Roundup

RoundupDesmosedigi, Part Due

July 2002 By Brian Catterson