AUTOMATIC FOR THE PEOPLE

AUTOMATIC TRANSMISSION, anyone? Motorcyclists thave traditionally answered with a resounding “No,” underscoring the importance of shifting to the two-wheeled experience. Case in point? Back in 1976, Honda’s CB750A had a true, three-element torque converter, which turned out to be the answer to the question no one asked.

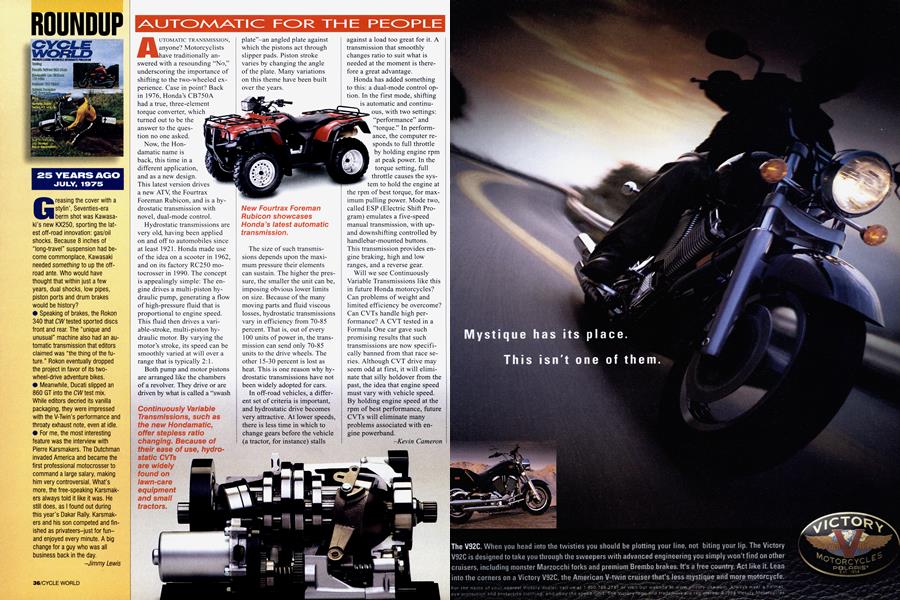

Now, the Hondamatic name is back, this time in a different application, and as a new design. This latest version drives a new ATV, the Fourtrax Foreman Rubicon, and is a hydrostatic transmission with novel, dual-mode control.

Hydrostatic transmissions are very old having been applied on and off to automobiles since at least 1921. Honda made use of the idea on a scooter in 1962, and on its factory RC250 motocrosser in 1990. The concept is appealingly simple: The engine drives a multi-piston hydraulic pump, generating a flow of high-pressure fluid that is proportional to engine speed. This fluid then drives a variable-stroke, multi-piston hydraulic motor. By varying the motor’s stroke, its speed can be smoothly varied at will over a range that is typically 2:1.

Both pump and motor pistons are arranged like the chambers of a revolver. They drive or are driven by what is called a “swash plate”-an angled plate against which the pistons act through slipper pads. Piston stroke varies by changing the angle of the plate. Many variations on this theme have been built over the years.

The size of such transmissions depends upon the maximum pressure their elements can sustain. The higher the pressure, the smaller the unit can be, imposing obvious lower limits on size. Because of the many moving parts and fluid viscous losses, hydrostatic transmissions vary in efficiency from 70-85 percent. That is, out of every 100 units of power in, the transmission can send only 70-85 units to the drive wheels. The other 15-30 percent is lost as heat. This is one reason why hydrostatic transmissions have not been widely adopted for cars.

In off-road vehicles, a different set of criteria is important, and hydrostatic drive becomes very attractive. At lower speeds, there is less time in which to change gears before the vehicle (a tractor, for instance) stalls against a load too great for it. A transmission that smoothly changes ratio to suit what is needed at the moment is therefore a great advantage.

Honda has added something to this: a dual-mode control option. In the first mode, shifting is automatic and continuous, with two settings: “performance” and “torque.” In performance, the computer responds to full throttle by holding engine rpm at peak power. In the torque setting, full throttle causes the system to hold the engine at the rpm of best torque, for maximum pulling power. Mode two, called ESP (Electric Shift Program) emulates a five-speed manual transmission, with upand downshifting controlled by handlebar-mounted buttons.

This transmission provides engine braking, high and low ranges, and a reverse gear.

Will we see Continuously Variable Transmissions like this in future Honda motorcycles? Can problems of weight and limited efficiency be overcome? Can CVTs handle high performance? A CVT tested in a Formula One car gave such promising results that such transmissions are now specifically banned from that race series. Although CVT drive may seem odd at first, it will eliminate that silly holdover from the past, the idea that engine speed must vary with vehicle speed. By holding engine speed at the rpm of best performance, future CVTs will eliminate many problems associated with engine powerband.

Kevin Cameror

View Full Issue

View Full Issue

More From This Issue

-

Up Front

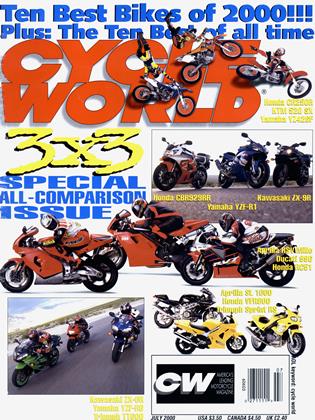

Up FrontThe Ten Rest, 2000

July 2000 By David Edwards -

Leanings

LeaningsThe Perfect Baja Bike

July 2000 By Peter Egan -

TDC

TDCCounting Cracks

July 2000 By Kevin Cameron -

Departments

DepartmentsHotshots

July 2000 -

Roundup

RoundupFriedel Münch Strikes Again

July 2000 By Kevin Cameron -

Roundup

RoundupAprilia Buys Moto Guzzi

July 2000 By Bruno De Prato