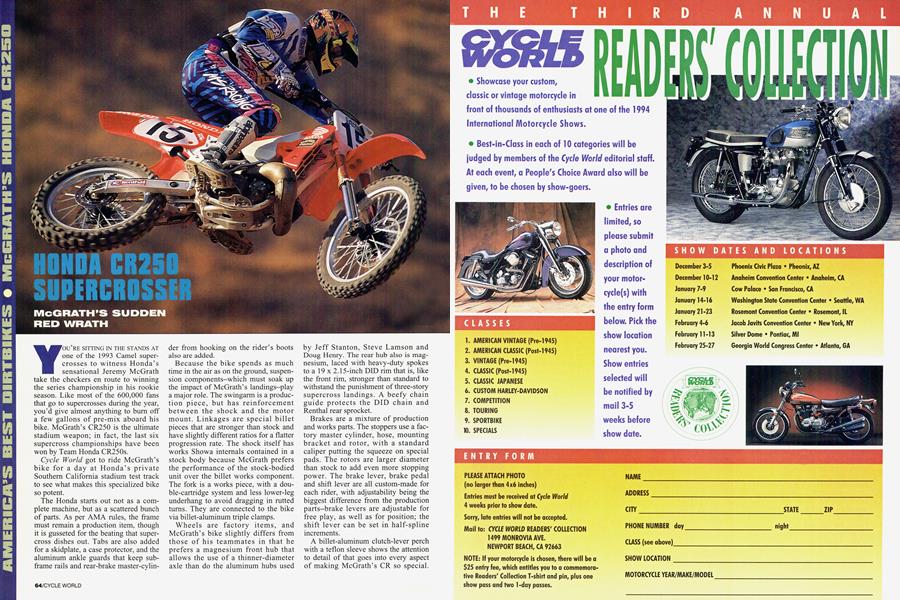

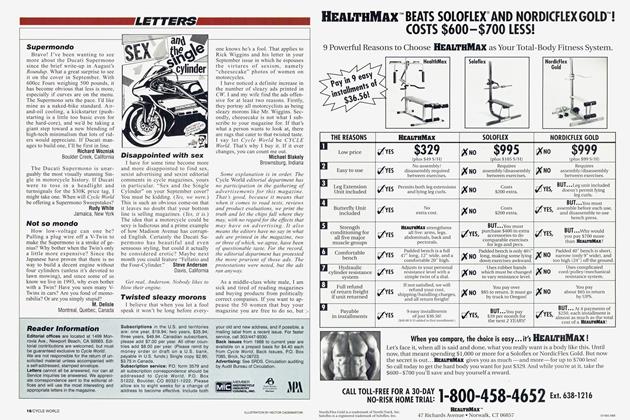

HONDA CR250 SUPERCROSSER

McGRATH'S SUDDEN RED WRATH

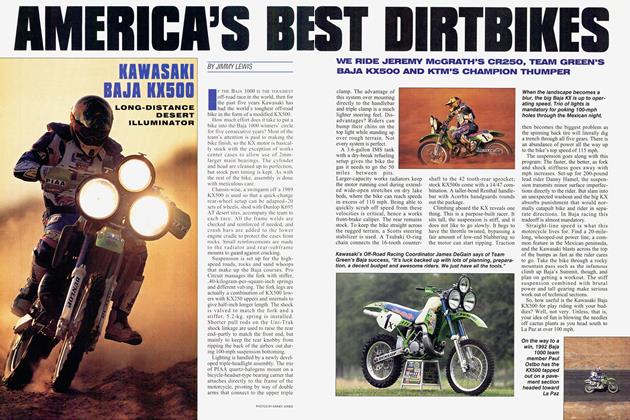

YOU’RE SITTING IN THE STANDS AT one of the 1993 Camel supercrosses to witness Honda’s sensational Jeremy McGrath take the checkers en route to winning the series championship in his rookie season. Like most of the 600,000 fans that go to supercrosses during the year, you’d give almost anything to burn off a few gallons of pre-mix aboard his bike. McGrath’s CR250 is the ultimate stadium weapon; in fact, the last six supercross championships have been won by Team Honda CR250s.

Cycle World got to ride McGrath’s bike for a day at Honda’s private Southern California stadium test track to see what makes this specialized bike so potent.

The Honda starts out not as a complete machine, but as a scattered bunch of parts. As per AMA mies, the frame must remain a production item, though it is gusseted for the beating that supercross dishes out. Tabs are also added for a skidplate, a case protector, and the aluminum ankle guards that keep subframe rails and rear-brake master-cylinder from hooking on the rider’s boots also are added.

Because the bike spends as much time in the air as on the ground, suspension components-which must soak up the impact of McGrath’s landings-play a major role. The swingarm is a production piece, but has reinforcement between the shock and the motor mount. Linkages are special billet pieces that are stronger than stock and have slightly different ratios for a flatter progression rate. The shock itself has works Showa internals contained in a stock body because McGrath prefers the performance of the stock-bodied unit over the billet works component. The fork is a works piece, with a double-cartridge system and less lower-leg underhang to avoid dragging in rutted turns. They are connected to the bike via billet-aluminum triple clamps.

Wheels are factory items, and McGrath’s bike slightly differs from those of his teammates in that he prefers a magnesium front hub that allows the use of a thinner-diameter axle than do the aluminum hubs used by Jeff Stanton, Steve Lamson and Doug Henry. The rear hub also is magnesium, laced with heavy-duty spokes to a 19 x 2.15-inch DID rim that is, like the front rim, stronger than standard to withstand the punishment of three-story supercross landings. A beefy chain guide protects the DID chain and Renthal rear sprocket.

Brakes are a mixture of production and works parts. The stoppers use a factory master cylinder, hose, mounting bracket and rotor, with a standard caliper putting the squeeze on special pads. The rotors are larger diameter than stock to add even more stopping power. The brake lever, brake pedal and shift lever are all custom-made for each rider, with adjustability being the biggest difference from the production parts-brake levers are adjustable for free play, as well as for position; the shift lever can be set in half-spline increments.

A billet-aluminum clutch-lever perch with a teflon sleeve shows the attention to detail of that goes into every aspect of making McGrath’s CR so special.

Renthal provides the handlebars and grips. Titanium graces most of the bike from its axles and engine-mount bolts to the fasteners and washers that hold on all of the plastic.

The motor starts life as a set of production center cases to comply with regulations. The majority of the transmission is stock, with the exception of second gear, which is slightly taller to bring it closer to third gear than showroom CRs. The crank, rod, piston and bearings are all special, with near-perfect tolerances. The cylinder, head and powervalves are all production items set to works settings. The clutch pack is production, but the ignition is a digital unit that can be tuned by changing the chips in its black box. The engine sidecovers are magnesium; the clutch side allowing access to the powervalve-govemor springs so settings can be dialedin for various tracks. Most of the sidecover bolts are aluminum, while the center cases are held by titanium

hardware. The carburetor is standard, with vent lines similar to those of the 1994 CRs, and sends its air-fuel charge through stock reeds. The pipe is a oneoff to match the works cylinder porting. Throttle response is fierce; right off idle, the bike snaps at the slightest twitch of the grip. This is where McGrath gets the explosive power to launch over 80-foot triple-jumps from an almost-standing start. The CR pulls cleanly and with incredible strength throughout the rev range.

Suspension is very stiff, great for landing from huge sky-shot jumps, but seemingly too harsh everywhere else, reluctant to absorb even stadium-style whoops. The problem was the speed I was riding the bike. Where I was in first gear, pogo-sticking through the whoops, McGrath would be up two cogs, slamming across the tops. Factory mechanic Cliff White suggested that I “just pin the throttle in third and close your eyes, then it will work.”

So you still want to ride a factory Honda supercross bike? Take our advice and stick to the Stockers. Team Honda’s CR250 is too much for all but the top riders in the world. Truly awesome, but not for everybody.

View Full Issue

View Full Issue