SERVICE

JOE MINTON

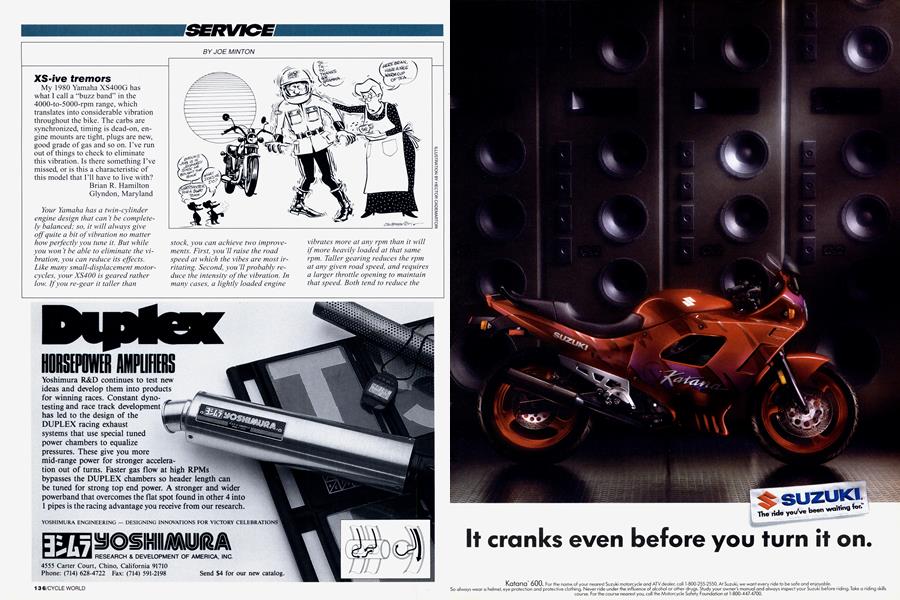

XS-ive tremors

My 1980 Yamaha XS400G has what I call a “buzz band” in the 4000-to-5000-rpm range, which translates into considerable vibration throughout the bike. The carbs are synchronized, timing is dead-on, engine mounts are tight, plugs are new, good grade of gas and so on. I’ve run out of things to check to eliminate this vibration. Is there something I’ve missed, or is this a characteristic of this model that I’ll have to live with?

Brian R. Hamilton Glyndon, Maryland

Your Yamaha has a twin-cylinder engine design that can 't be completely balanced; so, it will always give off quite a bit of vibration no matter how perfectly you tune it. But while you won’t be able to eliminate the vibration, you can reduce its effects. Like many small-displacement motorcycles, your XS400 is geared rather low. If you re-gear it taller than stock, you can achieve two improvements. First, you ’ll raise the road speed at which the vibes are most irritating. Second, you ’ll probably reduce the intensity of the vibration. In many cases, a lightly loaded engine

vibrates more at any rpm than it will if more heavily loaded at that same rpm. Taller gearing reduces the rpm at any given road speed, and requires a larger throttle opening to maintain that speed. Both tend to reduce the amount of vibration a rider feels.

Other factors also affect how much vibration you feel. Soft handgrips may help, as can a soft seat. Even the boots and socks you wear will have an effect on how much vibration you perceive. Consider just where on your body you feel the most vibration and add some padding there. My 1976 BMW R90Sfelt smoothest when it was cold out and I was wearing my thick gloves, lined boots, heavy socks and cold-weather riding suit.

Big-bang theories

I own a ’90 Honda Gold Wing with 6000 miles, bought new and carefully broken-in. It softly backfires after it’s downshifted to second or first on a steep hill with the revs up. If very quickly shifted under the same conditions, it might make a bang. The idle is slightly uneven, but it otherwise runs perfectly. I’ve changed the air filter, sparkplugs, fuel filter, used premium gas, checked engine sensors and carb starter valves, adjusted the idle air screws, idle speed and synched carbs to spec. My mechanic says this symptom is normal for high-rev engine braking. What do you think?

Dan Alderman Vancouver, British Columbia

The soft backfire you describe is common to motorcycles—or some cars, for that matter-and is caused by an over-lean condition. Thankfully, I'm not aware of an instance where it has harmed an engine.

When you close the throttle, you not only shut off'most of the air going to the engine but you also eliminate all but the idle circuits in the carburetors. At moderate to high rpm, an engine can draw more air through the nearly closed throttle valves than the idle circuits can keep up with, particularly on current EPA-lean engines. The result can be an excessively lean mixture that doesn't burn reliably. It thus tends to collect in the exhaust system, where the heat of the escaping gases will, from time to time, ignite it, causing a backfire. Any small air leaks in the exhaust system will make these popping noises louder and more prevalent.

What’s more, all Honda GL 1500s use vacuum-operated air valves that dramatically lean the mixture during throttle overrun. The six-cylinder Gold Wing engines have very little flywheel effect, and the ultra-lean mixture causes the engine to rev down much more slowly, thereby artificially simulating the effect of greater flywheel inertia.

The old swingarm slide

I’m very pleased with my ’91 Kawasaki Zephyr 750’s overall ability and feel, especially after installing a Progressive Suspension fork-spring kit. But the swingarm has, by my measurements, .07-inch side-to-side play along the swingarm pivot. The factory says .08-inch is okay, but why build that big, box-aluminum swingarm for stiffness just to allow play at the pivot point? The bike seems a little squirrely at speed in a straight line, but otherwise I haven’t felt a noticeable problem.

Should I worry about this? Should it be fixed, and how?

Daryl Wade Austin, Texas

Kawasaki specifies that its current streetbikes should have no more than 0.5mm (.02-inch) of side-to-side play of the swingarm at the pivot. The play should be measured only after the swingarm bearings have been lubricated with grease and the swingarm bolt has been torqued to the specification listed in the shop manual.

If the play is greater than 0.5mm, you ’ll need to adjust it. The factory recommends the use of appropriately sized shims from one of numerous Kawasaki transmissions. These shims are very hard and precise in their thickness. Be sure to measure the play at the swingarm pivot and not at the rear-wheel axle; a small amount of play at the pivot will be greatly multiplied back at the axle.

In addition to wearing out very quickly, dry bearings will exaggerate your sense of just how much play actually exits. And loose swingarm bearings can result in high-speed weave instability. Weave is not generally dangerous but can be very unsettling. It ’s possible that the squirrely feel you mentioned is a minor case of weave brought on by excessive swingarm play.

Imbalancing act

In mv January, 1992, Service column, I supported the use of Balance Plus tire-balancing fluid. In a subsequent letter to the magazine, the owner of a motorcycle service shop took exception to my recommendation, and stated that his customers had reported some very> poor results with balancing and flat-proofing fluids. In his experience, some of these fluids have caused enough corrosion of aluminum rims to create leaks around the beads. He also objects to the gooey mess that he or a fellow mechanic has to clean when replacing a tire. And he doesn’t trust a patch on any tire that has been subjected to these fluids. He also reminded me that the tire manufacturers strongly recommend against the use of balancing or flat-proofing fluids.

There are quite a few products on the market that are sold as balancing fluids/jlat-proofing treatments, but many simply don’t work. Some will corrode aluminum. None should be counted upon to seal a puncture. And none is a substitute for regular, frequent tire inspection.

Tire manufacturers recommend against all such fluids for good reasons: I) They can’t advocate the use of something they have no control over, even if the product works; and 2) if the tire companies did recommend one particular tire fluid, the other fluid manufacturers (or their lawyers) would no doubt file suit.

Some years ago, I conducted a wellcontrolled, subjective test of Balance Plus. I first dynamically balanced the front wheel of a BMW R80 with lead weights. I then taped 150 grams (5plus ounces) of lead to the wheel to throw it way out of balance. As a result, at 100 mph the tire would bounce clear off the ground. After I added 5 ounces of Balance Plus, the imbalance was significantly reduced but still rather severe. After several more trials, each with fewer unbalancing weights, I found that Balance Plus would nullify the effect of 60 grams of imbalance up to 90 mph, with only a slight vibration showing up at 100 mph.

So, the stuff works. I have put more than 250,000 miles on motorcycles with Balance Plus in their tires, wearing out at least 20 sets of tires in the process, and none have worn unevenly or showed any signs of imbalance. I 've never seen any corrosion of the wheels. And I’ve patched several tires that had been treated with Balance Plus, but never encountered any subsequent problems. I highly recommend this product-but only this product.

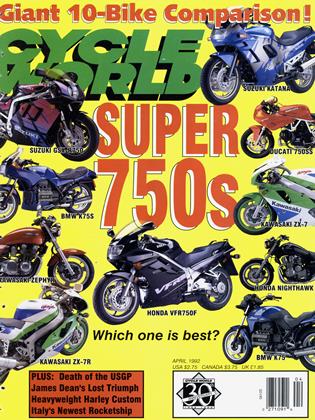

View Full Issue

View Full Issue

More From This Issue

-

Up Front

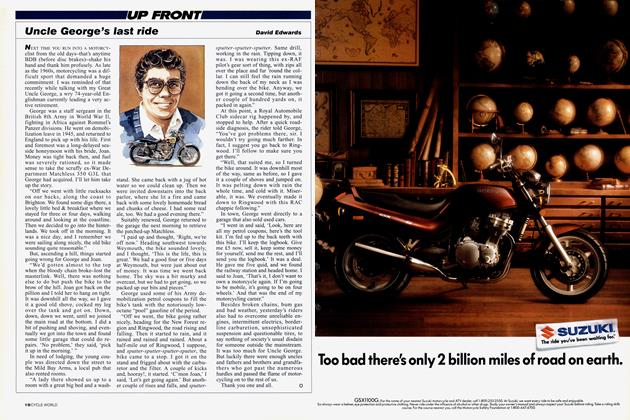

Up FrontUncle George's Last Ride

April 1992 By David Edwards -

Leanings

LeaningsThe Enchanted Vagabond

April 1992 By Peter Egan -

TDC

TDCRocket Fuel

April 1992 By Kevin Cameron -

Letters

LettersLetters

April 1992 -

Roundup

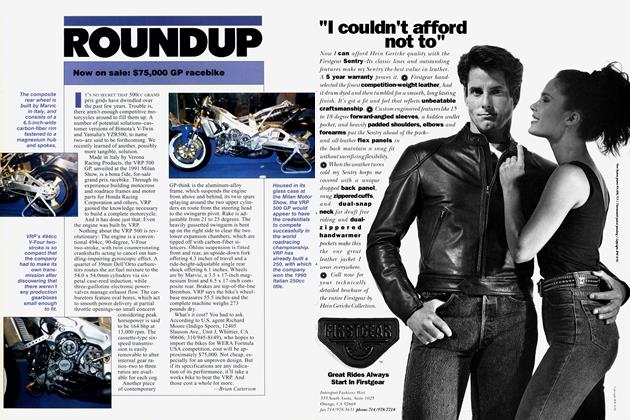

RoundupNow On Sale: $75,000 Gp Racebike

April 1992 By Brian Catterson -

Roundup

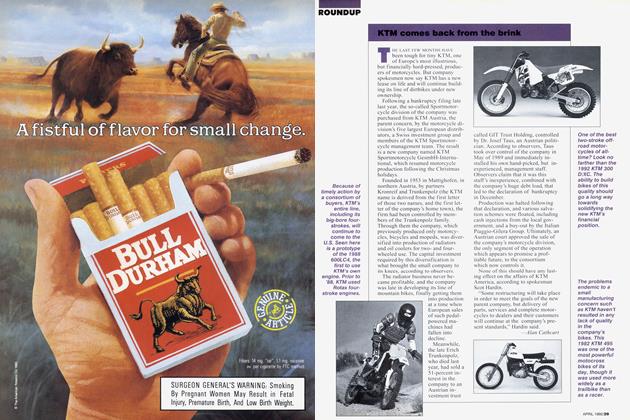

RoundupKtm Comes Back From the Brink

April 1992 By Alan Cathcart