Works Performance Shock Rebuild

EVALUATION

How to cure suspension ills without spending $400 on a new shock.

How easy it sounds, when you read that the solution to your handling problems is to pitch the stock rear shock and replace it with a $400 substitute. Just unbolt the old one and bolt in the new one. There. All fixed.

Suspension parts have changed since a new set of shocks cost $30. The original equipment parts are better now, and many of the parts on the suspension systems are more expensive. Replacement springs usually cost over $100 on a single shock bike. The cheapest is over $40. And just because the owner's manual says optional spring rates are available, they may not be available at your dealer.

This leads to the custom rebuilt shock. The same people who make replacement suspension parts often rebuild stock parts. Pull off your old shock, send it to the factory, and back it comes with mod ified spring, damping or whatever you request.

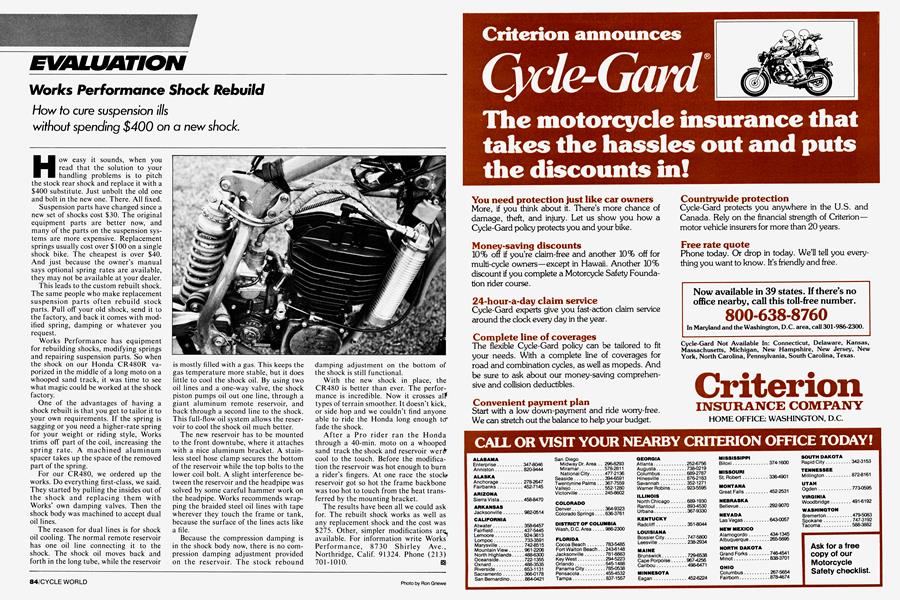

Works Performance has equipment for rebuilding shocks, modifying springs and repairing suspension parts. So when the shock on our Honda CR48OR va porized in the middle of a long moto on a whooped sand track, it was time to see what magic could be worked at the shock factory.

One of the advantages of having a shock rebuilt is that you get to tailor it to your own requirements. If the spring is sagging or you need a higher-rate spring for your weight or riding style, Works trims off part of the coil, increasing the spring rate. A machined aluminum spacer takes up the space of the removed part of the spring.

For our CR480, we ordered up the works. Do everything first-class, we said. They started by pulling the insides out of the shock and replacing them with Works' own damping valves. Then the shock body was machined to accept dual oil lines.

The reason for dual lines is for shock oil cooling. The normal remote reservoir has one oil line connecting it to the shock. The shock oil moves back and forth in the long tube, while the reservoir

is mostly filled with a gas. This keeps the gas temperature more stable, but it does little to cool the shock oil. By using two oil lines and a one-way valve, the shock piston pumps oil out one line, through a giant aluminum remote reservoir, and back through a second line to the shock. This full-flow oil system allows the reser voir to cool the shock oil much better.

The new reservoir has to be mounted to the front downtube, where it attaches with a nice aluminum bracket. A stain less steel hose clamp secures the bottom of the reservoir while the top bolts to the lower coil bolt. A slight interference be tween the reservoir and the headpipe was solved by some careful hammer work on the headpipe. Works recommends wrap ping the braided steel oil lines with tape wherever they touch the frame or tank, because the surface of the lines acts like a file.

Because the compression damping is in the shock body now, there is no com pression damping adjustment provided on the reservoir. The stock rebound

damping adjustment on the bottom of the shock is still functional.

With the new shock in place, the CR480 is better than ever. The perfor mance is incredible. Now it crosses al~ types of terrain smoother. It doesn't kick, or side hop and we couldn't find anyone able to ride the Honda long enough t~ fade the shock.

After a Pro rider ran the Honda through a 40-mm. moto on a whooped sand track the shock and reservoir wert~ cool to the touch. Before the modifica tion the reservoir was hot enough to burn a rider's fingers. At one race the stock! reservoir got so hot the frame backbone was too hot to touch from the heat trans ferred by the mounting bracket.

The results have been all we could ask for. The rebuilt shock works as well as any replacement shock and the cost was $275. Other, simpler modifications ar~ available. For information write Works Performance, 8730 Shirley Ave., Northridge, Calif. 91324. Phone (213) 701-1010.