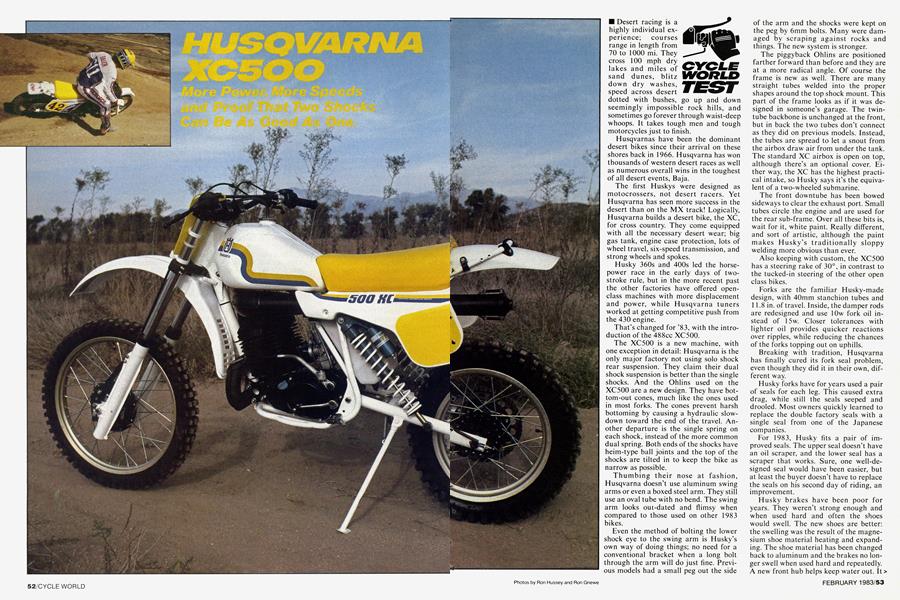

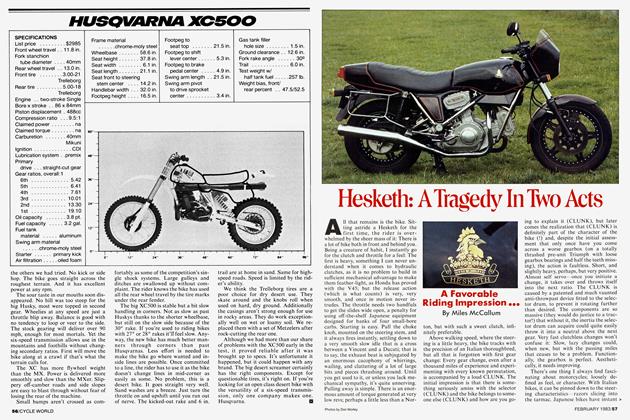

HUSQVARNA XC500

More Power, More Speeds and Proof That Two Shocks Can Be As Good As One.

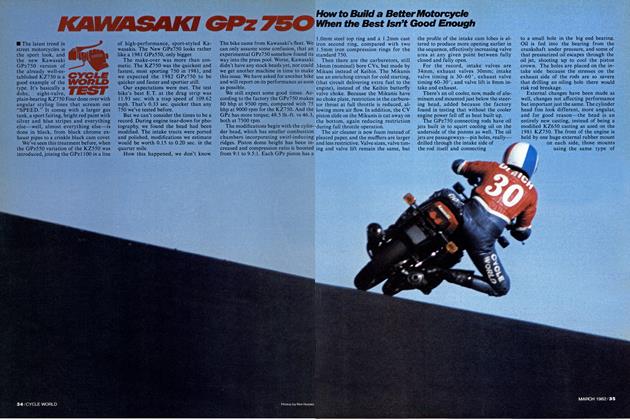

CYCLE WORLD TEST

■ Desert racing is a highly individual experience; courses range in length from 70 to 1000 mi. They cross 100 mph dry lakes and miles of sand dunes, blitz down dry washes, speed across desert

dotted with bushes, go up and down seemingly impossible rock hills, and sometimes go forever through waist-deep whoops. It takes tough men and tough motorcycles just to finish.

Husqvarnas have been the dominant desert bikes since their arrival on these shores back in 1966. Husqvarna has won thousands of western desert races as well as numerous overall wins in the toughest of all desert events, Baja.

The first Huskys were designed as motocrossers, not desert racers. Yet Husqvarna has seen more success in the desert than on the MX track! Logically, Husqvarna builds a desert bike, the XC, for cross country. They come equipped with all the necessary desert wear; big gas tank, engine case protection, lots of wheel travel, six-speed transmission, and strong wheels and spokes.

Husky 360s and 400s led the horsepower race in the early days of twostroke rule, but in the more recent past the other factories have offered openclass machines with more displacement and power, while Husqvarna tuners worked at getting competitive push from the 430 engine.

That’s changed for ’83, with the introduction of the 488cc XC500.

The XC500 is a new machine, with one exception in detail: Husqvarna is the only major factory not using solo shock rear suspension. They claim their dual shock suspension is better than the single shocks. And the Ohlins used on the XC500 are a new design. They have bottom-out cones, much like the ones used in most forks. The cones prevent harsh bottoming by causing a hydraulic slowdown toward the end of the travel. Another departure is the single spring on each shock, instead of the more common dual spring. Both ends of the shocks have heim-type ball joints and the top of the shocks are tilted in to keep the bike as narrow as possible.

Thumbing their nose at fashion, Husqvarna doesn’t use aluminum swing arms or even a boxed steel arm. They still use an oval tube with no bend. The swing arm looks out-dated and flimsy when compared to those used on other 1983 bikes.

Even the method of bolting the lower shock eye to the swing arm is Husky’s own way of doing things; no need for a conventional bracket when a long bolt through the arm will do just fine. Previous models had a small peg out the side of the arm and the shocks were kept on the peg by 6mm bolts. Many were damaged by scraping against rocks and things. The new system is stronger.

The piggyback Ohlins are positioned farther forward than before and they are at a more radical angle. Of course the frame is new as well. There are many straight tubes welded into the proper shapes around the top shock mount. This part of the frame looks as if it was designed in someone’s garage. The twintube backbone is unchanged at the front, but in back the two tubes don’t connect as they did on previous models. Instead, the tubes are spread to let a snout from the airbox draw air from under the tank. The standard XC airbox is open on top, although there’s an optional cover. Either way, the XC has the highest practical intake, so Husky says it’s the equivalent of a two-wheeled submarine.

The front downtube has been bowed sideways to clear the exhaust port. Small tubes circle the engine and are used for the rear sub-frame. Over all these bits is, wait for it, white paint. Really different, and sort of artistic, although the paint makes Husky’s traditionally sloppy welding more obvious than ever.

Also keeping with custom, the XC500 has a steering rake of 30°, in contrast to the tucked-in steering of the other open class bikes.

Forks are the familiar Husky-made design, with 40mm stanchion tubes and 11.8 in. of travel. Inside, the damper rods are redesigned and use lOw fork oil instead of 15w. Closer tolerances with lighter oil provides quicker reactions over ripples, while reducing the chances of the forks topping out on uphills.

Breaking with tradition, Husqvarna has finally cured its fork seal problem, even though they did it in their own, different way.

Husky forks have for years used a pair of seals for each leg. This caused extra drag, while still the seals seeped and drooled. Most owners quickly learned to replace the double factory seals with a single seal from one of the Japanese companies.

For 1983, Husky fits a pair of improved seals. The upper seal doesn’t have an oil scraper, and the lower seal has a scraper that works. Sure, one well-designed seal would have been easier, but at least the buyer doesn’t have to replace the seals on his second day of riding, an improvement.

Husky brakes have been poor for years. They weren’t strong enough and when used hard and often the shoes would swell. The new shoes are better: the swelling was the result of the magnesium shoe material heating and expanding. The shoe material has been changed back to aluminum and the brakes no longer swell when used hard and repeatedly. A new front hub helps keep water out. It > has the small side spoke flange cast-in, replacing the pressed-on steel part. The large diameter spokes still make a tight bend as they exit the hub flange but they are strong. The weak front brake has been cured by a double-leading shoe setup. The brake hub remains 6.3 in., the largest of any dirt bike. The rear hub is the same strong part first seen a couple of years ago. It too has large spokes that make a sharp bend as they leave the hub.

We saw the first 488cc Husky engine in motocross form in mid-year ’82. The XC500 engine has the same 86 x 84mm bore and stroke but many parts are different: A 40mm Mikuni is used instead of the huge 44mm carb the mid-year bike had. Additionally, a six-speed transmission is standard. The transmission has many new parts for ’83; the shift forks have about 30 percent more surface area to better engage the shifted gears, eliminate bending and make shifting more positive. Third and fourth gears have been strengthened considerably and the three gears that have shift rings on them (the ones the shift forks fit into) are stronger.

The XC also has an external-flywheel magneto with a 35w lighting coil. It will run an enduro-legal headlight but serious off-road racing after sunset will require a change to the 140w SEM ignition from the enduro WR. Primary kick starting is standard and the clutch cover can be removed without removing the shift lever or the weird-bend kick start lever. The clutch is the same size and has the same number of plates as last year’s 430 and 250. The clutch basket is beefed and stronger clutch springs handle the added power. The new cylinder has the reed cage cavity cast-in.

The new rear frame section has eliminated Husky’s famous quick change air filter. The new filter is large and made of foam but requires removal of the seat for service. The seat is still held on with two 6mm bolts and lock nuts. Too bad they didn’t weld the nuts to the frarrle so removal could be accomplished with a single wrench. Once the seat is off the filter is easy to remove, still held in place with a spring wire.

Huskys have had white plastic fenders and aluminum gas tanks for years. For ’83 the plastic parts are thicker. The aluminum gas tank is larger for the XC, holding 3.2 gal. And, for the first time ever, the tank’s sides are completely painted. Thick, clear plastic protectors are standard for ’83 and keep the paint on the sides of the tank. The side number plates look more a part of the bike than before but their design lets them stick out about an inch farther than the top shock bolts, making the bike wider than necessary. Steel prongs plug into rubber grommets to hold the right sidecover in place, with one prong and a bolt holding the left sidecover. The right sidecover didn’t fit tightly on our bike, but it didn’t get ripped off the bike by any trees. It looks vulnerable. For off-road riding we’d remove the sidecovers to make the bike narrower.

A hard seat and low-rise handlebars make for a riding position unlike previous Huskys. The low handlebars force a rider to lean over the front of the bike, which is the wrong position for a desert bike.

Using the harder foam in the seat may be better in the long run, because it is less likely to sack. The yellow seat cover is another matter. Not only does it look odd, keeping it clean is impossible. It gets black and nasty looking just sitting in the garage. Cleaning it with contact cleaner doesn’t work either. That takes the paint off the side decals because the decals’ dye is on the outside instead of underneath, so you have to buy new decals to keep the bike looking nice.

Starting the big Husky isn’t fun. Husky again does things the Husky way: the weird kick lever and internal mechanism that doesn’t engage until the kick lever is half way through its stroke means you and probably two of your friends will have their tongues hanging out by the time the bike fires when cold. Warm, it’s easier. This system worked okay on Husky’s smaller engines once the rider learned to give the lever several quick kicks so the engine could spin fast enough to get spark from the ignition. With the 488cc engine it’s impossible to do. The Mikuni on our test bike had a float needle that didn’t do its job well. If the petcock wasn’t turned off and the bike sat for long, the engine would be flooded. We checked for dirt and proper float level but the problem persisted.

Once running the engine has a bad low-frequency vibration. Blipping the throttle while the engine warms turns the ends of the bars into a blur and makes the seat of your pants tingle. Putting the bike in gear and letting the clutch out eliminates much of the vibration; it’s still there when the engine is wound out but much less noticeable at lower revs.

Shifting is smooth and positive as long as the rider remembers to move his foot a long way: Our test bike had about an inch of slop at the end of the lever. That, added to a rather long throw, made for lots of missed shifts. No rider had any good words to say about the clutch action either. It has a spongy, vague feel to it. We had no clutch failures but it does heat quickly if slipped more than once.

We had a rash of small problems before the first 25 mi. About 3 mi. into the first ride, the bike suddenly came to a dead stop in the middle of a sandwash. Sounded like a fouled spark plug but it wasn’t. The plug wire was held in place with a plastic tie as it left the head, common on Huskys. But, the wire was too long and touched the head. The heat from the head melted the insulation and shorted. Some electrical tape and another tie to keep the wire off the head made a good field fix. About 20 mi. out the bike started losing top-end power. This is a common problem on Huskys equipped with spark arresters. The fine screen in the arrester was clogged. We removed the screen so the exhaust could get out. A couple of miles farther and the bike started vibrating badly. The rubber strap that insulates the front pipe hanger from the frame was gone. Older models often suffered the same problems with the rubber strap. It should be glued to the hanger bracket. The engine bolts had also loosened, adding to the vibration. A quick check of the rest of the nuts and bolts on the XC found the lower shock bolts had loosened badly. The engine bolts stopped loosening after they had been tightened a couple more times. The lower shock bolts stopped loosening after the threads were cleaned and doused with Loc-tite.

Once the small things were sorted out we got down to serious testing. Our bike proved baffling and disappointing. The rear of the bike had a habit of kicking sideways quickly and violently after crossing any kind of angled rut. It would jump out to the side and return just as quickly. It also kicked straight up when crosing lips. But probably the most disappointing thing was the absence of midrange horsepower. It was plain lacking in mid-range power. There was plenty of power down low and at peak revs, hardly any in the middle. The bike also reacted strangely in corners; the rear would suddenly jump into the corner, the front would take more time to react. It was like two different chassis were mated. Seven different riders tried the bike.

None thought it worked right. Finally one of our pro test riders seized the piston during a grand prix race. We called Husky and reported our problems. They assured us the bike wasn’t normal.

Before Husqvarna could trace the problems associated with our XC500, their press day rolled around. We tried two other XC500s and they were not at all like ours. Power was plentiful everyplace. And the rear suspension didn’t kick up or sideways.

Back at the shop we removed our bike’s head and cylinder. The piston top was badly pitted and one edge was gone. We only heard pinging just before it stuck, but apparently the massive finning on the barrel had masked the noise of slow destruction.

The bike went back to Husqvarna for a complete tear-down. They didn’t find any seal or gasket leaks. Piston aside, the engine was in good shape.

Their notes, though, showed the preparation crew had leaned the midrange with a smaller-than-stock needle jet before delivery to us. That would explain the lack of mid-range power. A toolean mid-range will kill the power. Normally a ping would let the rider know. We had raised the needle (lowered the needle clip) one notch during one of our outings before piston failure, but didn’t notice too much difference. The engine may have started running leaner after it got a couple of hundred miles on it. It sometimes happens.

The handling problems with the rear of the bike proved to be low nitrogen pressure in one of the shocks. They are supposed to have 185 psi in each shock. One of ours was pressurized at 185 psi, the other only had 85 psi. That explained the weird side jump and generally flexy feel of the back of the bike. With the shocks working at different rates, the swing arm was constantly being twisted. The twisting had a steering effect on the bike, causing it to wander around on the straights and side jump when crossing ruts.

After the fix our test bike worked like > the others we had tried. No kick or side hop. The bike goes straight across the roughest terrain. And it has excellent power at any rpm.

HUSQVARNA

XC500

SPECIFICATIONS

List price $2985

The sour taste in our mouths soon disappeared. No hill was too steep for the big Husky, most were topped in second gear. Wheelies at any speed are just a throttle blip away. Balance is good with no tendency to loop or veer to the side. The stock gearing will deliver over 90 mph, enough for most mortals. Yet the six-speed transmission allows use in the mountains and foothills without changing secondary ratios. First will move the bike along at a crawl if that’s what the terrain calls for.

The XC has more flywheel weight than the MX. Power is delivered more smoothly and slow than the MXer. Slippery off-camber roads and side slopes are easy to blast through without fear of losing the rear of the machine.

Small bumps aren’t crossed as comfortably as some of the competition’s single shock systems. Large gulleys and ditches are swallowed up without complaint. The rider knows the bike has used all the rear wheel travel by the tire marks under the rear fender.

The big XC500 is stable but a bit slow handling in corners. Not as slow as past Huskys thanks to the shorter wheelbase, but still on the slow side because of the 30° rake. If you’re used to riding bikes with 27° or 28° rakes it’ll feel slow. Anyway, the new bike has much better manners through corners than past Husqvarnas. Less effort is needed to make the bike go where wanted and inside lines are possible. Once committed to a line, the rider has to use it as the bike doesn’t change lines in mid-corner as easily as some. No problem, this is a desert bike. It goes straight very well. Sand washes are a breeze. Just turn the throttle on and upshift until you run out of nerve. The kicked-out rake and 6 in. trail are at home in sand. Same for highspeed roads. Speed is limited by the rider’s ability.

We think the Trelleborg tires are a poor choice for dry desert use. They skate around and the knobs roll when used on hard, dry ground. Additionally the casings aren’t strong enough for use in rocky areas. They do work exceptionally well on wet or loamy soil. We replaced them with a set of Metzelers after rock-cutting the rear one.

Although we had more than our share of problems with the XC500 early in the test, it proved reliable after it was brought up to specs. It’s unfortunate it happened, but it could happen with any brand. The big desert screamer certainly has the right components. Except for questionable tires, it’s right on. If you’re looking for an open class desert bike with the versatility of a six-speed transmission, only one company makes one. Husqvarna. BS

View Full Issue

View Full Issue