SERVICE

We welcome your technical questions and comments, and will publish those we think are of interest to our readers. Because of the volume of mail received, we cannot return any personal replies. Please limit your “Service” letters to technical subjects only, and keep them as brief as possible. Send them to: “Service,” CYCLE WORLD, 1499 Monrovia Ave., Newport Beach, Calif. 92663.

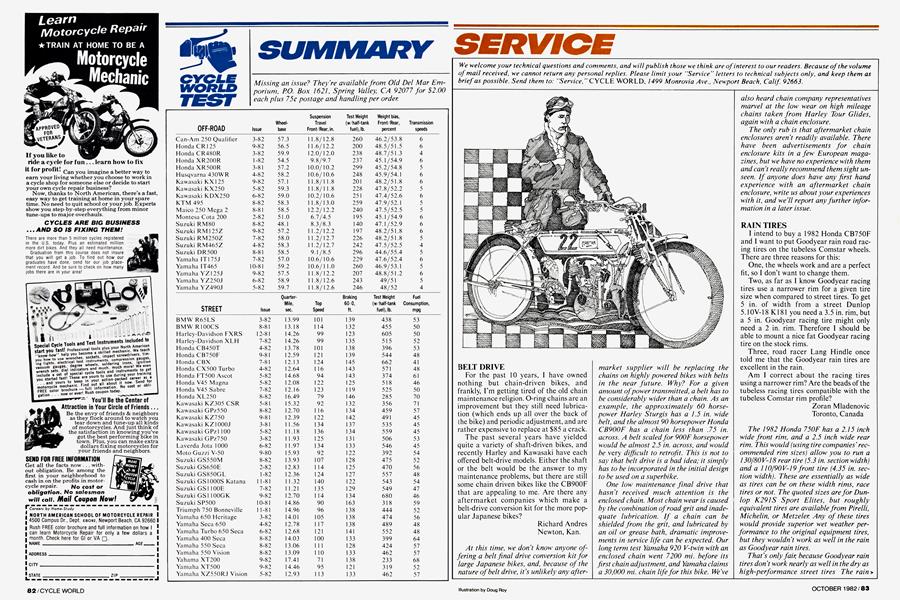

BELT DRIVE

For the past 10 years, 1 have owned nothing but chain-driven bikes, and frankly, I'm getting tired of the old chain maintenance religion. O-ring chains are an improvement but they still need lubrication (which ends up all over the back of the bike) and periodic adjustment, and are rather expensive to replace at $85 a crack.

The past several years have yielded quite a variety of shaft-driven bikes, and recently Harley and Kawasaki have each offered belt-drive models. Either the shaft or the belt would be the answer to my maintenance problems, but there are still some chain driven bikes like the CB900F that are appealing to me. Are there any aftermarket companies which make a belt-drive conversion kit for the more popular Japanese bikes?

Richard Andres Newton, Kan.

At this time, we don’t know anyone offering a belt final drive conversion kit for large Japanese bikes, and, because of the nature of belt drive, it’s unlikely any aftermarket supplier will be replacing the chains on highly powered bikes with belts in the near future. Why? For a given amount of power transmitted, a belt has to be considerably wider than a chain. As an example, the approximately 60 horsepower Harley Sturgis has a 1.5 in. wide belt, and the almost 90 horsepower Honda CB900F has a chain less than .75 in. across. A belt scaled for 900F horsepower would be almost 2.5 in. across, and would be very difficult to retrofit. This is not to say that belt drive is a bad idea; it simply has to be incorporated in the initial design to be used on a superbike.

One low maintenance final drive that hasn’t received much attention is the enclosed chain. Most chain wear is caused by the combination of road grit and inadequate lubrication. If a chain can be shielded from the grit, and lubricated by an oil or grease bath, dramatic improvements in service life can be expected. Our long term test Yamaha 920 V-twin with an enclosed chain went 7200 mi. before its first chain adjustment, and Yamaha claims a 30,000 mi. chain life for this bike. We’ve also heard chain company representatives marvel at the low wear on high mileage chains taken from Harley Tour Glides, again with a chain enclosure.

The only rub is that aftermarket chain enclosures aren’t readily available. There have been advertisements for chain enclosure kits in a few European magazines, but we have no experience with them and can’t really recommend them sight unseen. If anyone does have any first hand experience with an aftermarket chain enclosure, write us about your experiences with it, and we’ll report any further information in a later issue.

RAIN TIRES

I intend to buy a 1982 Honda CB750F and I want to put Goodyear rain road racing tires on the tubeless Comstar wheels. There are three reasons for this:

One, the wheels work and are a perfect fit, so I don’t want to change them.

Two, as far as I know Goodyear racing tires use a narrower rim for a given tire size when compared to street tires. To get 5 in. of width from a street Dunlop 5.10V-18 K181 you need a 3.5 in. rim, but a 5 in. Goodyear racing tire might only need a 2 in. rim. Therefore I should be able to mount a nice fat Goodyear racing tire on the stock rims.

Three, road racer Lang Hindle once told me that the Goodyear rain tires are excellent in the rain.

Am I correct about the racing tires using a narrower rim? Are the beads of the tubeless racing tires compatible with the tubeless Comstar rim profile?

Zoran Mladenovic Toronto, Canada

The 1982 Honda 750F has a 2.15 inch wide front rim, and a 2.5 inch wide rear rim. This would (using tire companies’ recommended rim sizes) allow you to run a 130/80V-18 rear tire (5.3 in. section width) and a 110/90V-19 front tire (4.35 in. section width). These are essentially as wide as tires can be on these width rims, race tires or not. The quoted sizes are for Dunlop K291S Sport Elites, but roughly equivalent tires are available from Pirelli, Michelin, or Metzeler. Any of these tires would provide superior wet weather performance to the original equipment tires, but they wouldn’t work as well in the rain as Goodyear rain tires.

That’s only fair, because Goodyear rain tires don’t work nearly as well in the dry as high-performance street tires The rain> tires were designed to work on wet (not damp) race tracks, and depend on splashing continuously through water to keep their operating temperature down. They’re very short-lived in dry conditions, and even under the relatively light duty of street riding will last through only a few hundred dry miles. In any case, the race tires are not legal for use on public roads, and Goodyear specifically recommends they not be used other than on race tracks. Unless you plan on racing in the rain, run street tires.

HONDA 750F2 VALVE GUIDES

Though I am a believer in Honda’s cycle technology, I had reason to doubt it recently. My 1978 CB750F was slowly beginning to use oil through a leaky number three exhaust valve guide. I had only about 5000 mi. on the machine when blue smoke began to follow me to stop lights. Also, on cold startups, engine oil leaked down the number three exhaust header and out in a small puddle underneath the 4-into-l collector junction area. I knew I had not abused the engine and it certainly was too soon for a top end job.

When queried, Honda of America told me they knew of only “a few spotty cases” of this problem with the ’78 black F-model engines. I authorized my local Honda dealer to repair/replace all exhaust guides and work out some sort of warranty deal through Honda, which he did. The dealer then informed me he has seen this problem on many F-model engines and attributed the problem to the guides themselves coupled with the more geometrically radical F cam which puts more side loading on the valve stem, thus wearing into the guides more.

The repair was to install 750K model guides in my head and touch up the valve seats and faces. That cured the oil consumption problem—at least for the 650 mi. since the top end job. Do I need to be concerned that the K guides will get the same treatment from the F bumpsticks and possibly wear too soon?

Joe Owen

Mesa, Ariz.

Honda was reacting to the very quick Suzuki GS750 when it updated the 750F into the F2 for 1977, and perhaps they let the search for increased power override their usual attention to durability. The changes made included a revised cylinder head with new combustion chambers and larger valves, a new exhaust system, revised carburetion, and a higher lift camshaft working in conjunction with stiffer valve springs. The cam is the heart of the problem. It uses the same duration and timing

as the camshaft used in the 1975-76 F models, but with more lift and steeper ramps. The resulting higher valve accelerations and greater loads have contributed to three problems that aren’t uncommon in the 1977-78 F2 models: excessive exhaust valve guide wear, broken valve spring retainers (mainly on the intake side), and intake valve stem breakage. Note that either of the last two problems will result in major engine damage.

Several local repair shops report some success in solving the valve guide wear problems by switching to 750K model valve guides. The K model guides are slightly longer than those used in the F2, and give a little more area to spread the side-thrust generated by the rocker arms and by valve seating. This change, according to our sources, extends valve guide life, but may not completely eliminate wear problems. The 750 Honda valve guides are not made from the best material available, and it’s possible that aftermarket valve guides may offer superior life; we can’t say that with certainty because we don’t know of any bikes that have been rebuilt with aftermarket guides and have then accumulated high mileage.

The valve spring retainer and valve stem breakage problems are less common, and probably resulted from out-of-tolerance or otherwise imperfect valve retainers and keepers on the early F2s. We suspect Honda, who redesigned the retainer and keepers for the F2, used machined-fromsolid parts on their prototype durability test engine and then ran into problems with their production stamped retainers. Machined aftermarket retainers (such as offered by Action Fours, 1517 E. McFadden Ave., Santa Ana, Calif. 92705) are good insurance against your engine suffering the same problems, and we would recommend the switch if you had the top end apart for some other reason.

WHEEL ALIGNMENT

I am interested in purchasing a wheel aligner such as the Henter Wheel Aligner which appeared in a product evaluation in your Feb., 1980 issue. I wrote to Henter Enterprises in Pinellas Park, Florida, but to no success.

I also have noticed that most motorcycle manuals are totally remiss when it comes to wheel alignment. Nothing is mentioned in the manuals whatsoever. Do motorcycle shops actually align wheels, and, if they do, what do they use? Do they just eyeball the alignment?

I hope there is some company that makes a decent wheel aligner. If there is, could you please give me their address.

Terry O’Donnell Rochester, N.Y.

The purpose of aligning the wheels is to ensure that both wheels are in the same plane, and that, when you’re riding straight down the road, both wheels are pointed straight ahead. This should be built into shaft driven machines as there are no adjustments that can be made. On a chain driven bike things are slightly more complicated because provision had to be made to move the rear wheel fore and aft to take up chain slack. In a perfect world you could use the stamped marks on the swing arm for alignment, but manufacturing tolerances are such that it’s possible to have the adjustment marks align when the rear wheel is slightly cocked. That’s why an alignment procedure is desirable.

As you suggest, eyeballing the alignment is a possibility, and for many applications is perfectly acceptable. The easiest way to do this is to place the motorcycle on level pavement, point the front wheel straight ahead, and while crouching in front of the bike, sight down the sides. Any gross misalignment of the rear wheel should be visible, and can be corrected by using the chain adjusters to pivot the rear wheel back into plane.

For high-speed, competitive uses such as roadracing, more precise alignment techniques have been used. One of the simpler methods involves using nothing more complicated than a 12 ft. length of string. The string is wrapped around the front of the front tire about 6-8 in. from the ground and then run straight back on both sides of the bike. Finally, the string is taped to the aft edge of the back tire. Any misalignment will show up in a gap between the string and the front portion of the rear tire, or in unequal gaps between the string and the rear of the front tire.

A more popular technique in recent years has been to use long straight edges to check alignment. Two roadrace tuners we know carry 6 ft. long Sears aluminum levels to the track as part of their standard tool kit. They can place the I-beam shaped levels against the rear tire and spot any misalignment in unequal gaps between the level and the front and rear edges of the front tire. While the Sears level may have the cachet of being used by Erv Kanemoto, an equally good job can be performed by any 6 ft. straight edge.

The Henter wheel aligner is a precise, expensive alternative to the methods mentioned above. While both the string and straight edge methods involve judging the dijference between small gaps, the Henter device magnifies any misalignment into an easily visible difference in its sighting system. While it offers improved accuracy, it does so at an improved cost—about $ 195.

Ted Henter is still making his wheel aligners, but his company has moved. The current address of Henter Engineering is 6526 Hobson St. N.E., St. Petersburg, Ela. 33703, phone (813) 522-2961. His wheel aligner is also sold by Motorace, P.O. Box 861, Wilbraham, Mass. 01095, phone (413) 734-6211.

REGROUND CRANKSHAFTS

My boy’s 1978 Yamaha XS400 ate a rear cam chain guide at 22,120 mi. The chain wore on the aluminum engine; the resulting chips plugged the crankshaft oil hole on one connecting rod and it seized. Probably a familiar story up to this point.

There were no undersize big end bearings produced for this bike, and the local dealer wanted $175 for a new crankshaft. Even a used crank was $116. No damn way, 1 decided. Instead I would see what American bearing manufacturers could do. None made bearings specifically for motorcycles but by searching through a couple of catalogs 1 found that Federal Mogul has a bearing for an International Harvester tractor, nearly identical to what I needed for the Yamaha, and in .030 undersize which is what I had to have the shaft ground down to. The Yamaha connecting rod I.D. was 1.615 in. The Federal Mogul bearing O.D. called for 1.62451.6250 in.—a negligible enlargement of the connecting rod. The original shaft measured 1.496 in. but since one journal was scored it didn’t matter because the machine shop ground it to fit the new bearing. The original bearing width was .772 in.; the Federal Mogul bearing is .761 in. wide.

The point of all this is to let you and your readers know that you can get bearings—U.S. made—to fit these bikes and you don't have to buy new crankshafts. Final cost: $8.02 for two bearings, $ 15 for resizing the connecting rods and $24 for regrinding the crank; $47.43 total including tax. All shop work was done by a local machine shop specializing in grinding crankshafts, and they took less time than ordering the new parts from Yamaha would have taken.

The XS400 is running beautifully and though only time will tell how well this job turns out, it’s like new now. I recommend this approach to any of your readers in a similar bind. If interested refer to either Federal Mogul Catalog 115 (1980) or Sealed Power Catalog 203-R81. Both are for engine bearings and contain all necessary dimensions for comparison. On my bike alone there were five different bearing numbers which fit; my guess is that this is true for most other bikes.

The tang on the catalog bearings may not be identical to the one in the bike but this is easily corrected by filing the grooves in the rod to match. Believe me— it really works!

Ray Rousseau East Freetown, Mass.

Your bearing substitution may work, but there is at least a potential problem in grinding the crank surface. All the plain bearing cranks in Japanese bikes have hardened main and big end bearing journals. Honda uses a carbonitrided surface treatment (similar to Tujj'triding or cyaniding) that produces a very hard, but shallow, wear surface. This hard layer is only a few thousandths of an inch thick, and would be removed by grinding the big end journal undersize. Softer steel would then be exposed, and you may (or may not) see substantially increased wear during ordinary street use.

American Yamaha representatives have only been able to tell us their crankshafts are hardened, probably by a flame hardening process, but they are not sure of the details. If the journals are hardened by a flame or induction hardening process, a deeper hard case would be produced than by carbonitriding processes, and more material could be removed without losing surface hardness.

Unfortunately there appears no easy or cheap way to replace hard surface lost to grinding. A few engine builders have experimented with replacing the normal carbonitrided case on Honda crankshafts with a layer of hard chrome, and have found this is more durable under extreme racing conditions. While this would eliminate any concern about wear problems with a regrouhd crank, it’s not economically attractive as your final cost would be more than for a new crankshaft. Hank the Crank, Inc. (7253 Lankershim BlvdNorth Hollywood, Calif. 91605, phone (213) 765-3444) will Tufftride bearing journals of four cylinder Japanese crankshafts. Once again, this is not an inexpensive process and the reworked crank would be comparable to a new crankshaft in cost. Also, they’re not equipped to handle any but the common four cylinder crankshafts.

So at this point we can’t say whether grinding crankshaft journals without replacing the hard surface is an acceptable fix or not. We can say that it’s more likely to give problems on crankshafts with superficial surface hardness rather than deep hardened cranks. As for your Yamaha, as you point out, only time will tell. Let us know if your repair holds up.

RICH LAVERDA

I recently moved from Michigan to Arkansas. The roads here are enough to make me think I’ve died and gone to heaven. However, the change has not been an agreeable one for the carburetion on my Laverda. After much experimentation I've determined the problem is the result of the slide cutaway being too rich. I’ve increased the cutaway by hand and it's improved the situation greatly. I would like to buy a set of slides with even more cutaway but I can’t find out who distributes Dell’Orto carburetors. Can you help?

Denny Albrecht

Hot Springs, Ark.

Dell’Orto curbs and parts are distributed by Ron Wood Racing Products, 755 West 17th Street, Unit D, Costa Mesa, Calif. 92626, phone (714) 645-0393. We’re puzzled about how moving to Arkansas changed your carburetion requirements. The maximum elevation change between Michigan and Arkansas is only about WOO ft., and that shouldn’t dramatically affect carburetion. Have you eliminated other potential causes of rich part throttle mixtures? Some things that might bear checking once you’re sure the rest of your engine is right are:

1. Curb synchronization.

2. Air filter cleanliness.

3. Float levels.

4. A leaky float valve.

5. An obstructed air bleed circuit.

6. A sticky choke or enrichment circuit. 0

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontAdvice To the Lovelorn

October 1982 By Allan Girdler -

Letters

LettersLetters

October 1982 -

Departments

DepartmentsRoundup

October 1982 -

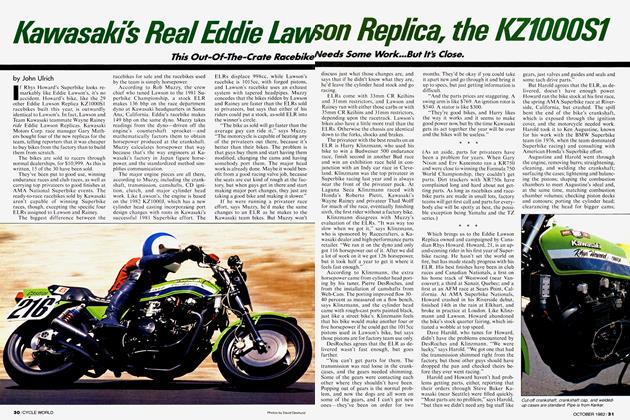

Competition

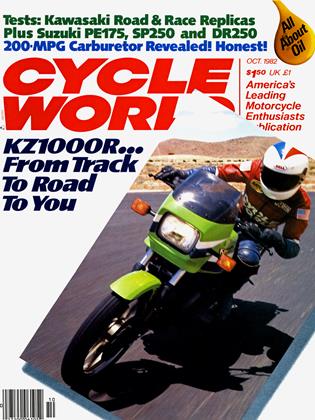

CompetitionKawasaki's Real Eddie Law Son Replica, the Kz1000s1

October 1982 By John Ulrich -

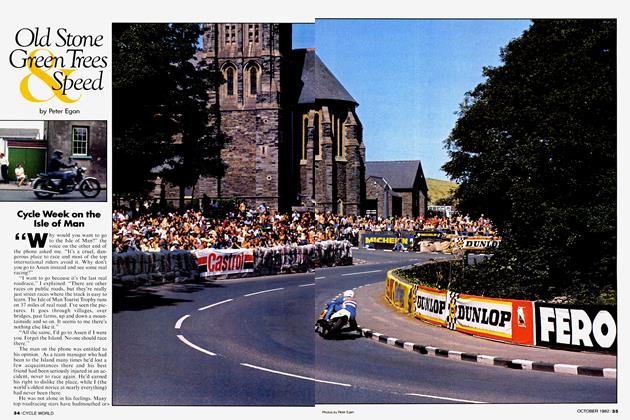

Features

FeaturesOld Stone Green Trees & Speed

October 1982 By Peter Egan -

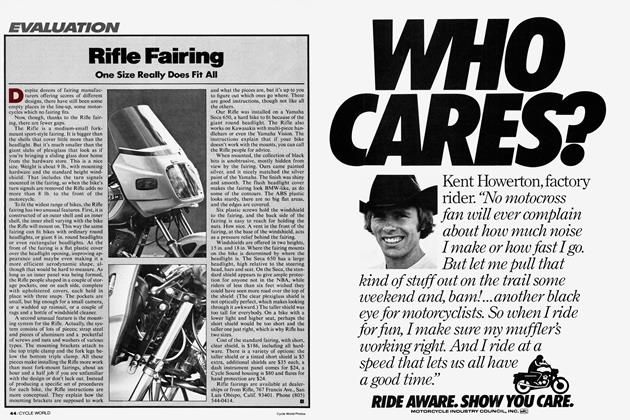

Evaluation

EvaluationRifle Fairing

October 1982