The Piston Ring Story

Bruce Sharp

What with rampant inflation, the world arms buildup and casual sex for sale on our nation's streetcorners, most of us don't spend much time thinking about piston rings. You can hardly blame us. Of all the parts in the reciprocating engine, the piston ring is certainly one of the least complicated, surpassed only by the head stud, or possibly the base gasket, for its apparent sim plicity. Yet the piston ring is one of the most vital components in determining the efficiency and longevity of an engine.

Without piston rings the piston itself would have to be cast to a machine fit, matched to fit snugly in its bore. Which would work fine until the engine fired, at which time the piston would heat up and promptly seize itself solid. Leaving enough clearance to account for the piston’s expansion would prevent proper compression of the air/fuel mixture. The piston rings, then, are responsible for providing a tight seal between the piston and cylinder wall. They also control the lubrication of the cylinder wall.

Initially it might seem that the piston rings’ task, if vital, is at least a fairly simple one. But the job is not so simple as it appears. The rings must function flawlessly under extremely harsh conditions such as worn cylinder walls or ring grooves, distorted walls due to improperly tightened head bolts, and expansion from intense heat, up to 1700°F.

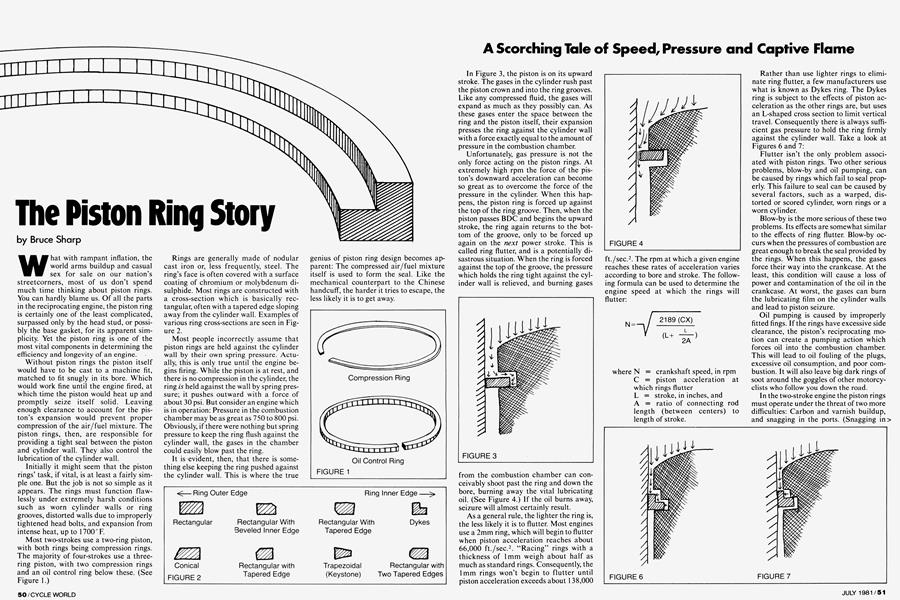

Most two-strokes use a two-ring piston, with both rings being compression rings. The majority of four-strokes use a threering piston, with two compression rings and an oil control ring below these. (See Figure 1.)

Rings are generally made of nodular cast iron or, less frequently, steel. The ring’s face is often covered with a surface coating of chromium or molybdenum disulphide. Most rings are constructed with a cross-section which is basically rectangular, often with a tapered edge sloping away from the cylinder wall. Examples of various ring cross-sections are seen in Figure 2.

Most people incorrectly assume that piston rings are held against the cylinder wall by their own spring pressure. Actually, this is only true until the engine begins firing. While the piston is at rest, and there is no compression in the cylinder, the ring is held against the wall by spring pressure; it pushes outward with a force of about 30 psi. But consider an engine which is in operation: Pressure in the combustion chamber may be as great as 750 to 800 psi. Obviously, if there were nothing but spring pressure to keep the ring flush against the cylinder wall, the gases in the chamber could easily blow past the ring.

It is-evident, then, that there is something else keeping the ring pushed against the cylinder wall. This is where the true

genius of piston ring design becomes apparent: The compressed air/fuel mixture itself is used to form the seal. Like the mechanical counterpart to the Chinese handcuff, the harder it tries to escape, the less likely it is to get away.

A Scorching Tale of Speed, Pressure and Captive Flame

In Figure 3, the piston is on its upward stroke. The gases in the cylinder rush past the piston crown and into the ring grooves. Like any compressed fluid, the gases will expand as much as they possibly can. As these gases enter the space between the ring and the piston itself, their expansion presses the ring against the cylinder wall with a force exactly equal to the amount of pressure in the combustion chamber.

Unfortunately, gas pressure is not the only force acting on the piston rings. At extremely high rpm the force of the piston’s downward acceleration can become so great as to overcome the force of the pressure in the cylinder. When this happens, the piston ring is forced up against the top of the ring groove. Then, when the piston passes BDC and begins the upward stroke, the ring again returns to the bottom of the groove, only to be forced up again on the next power stroke. This is called ring flutter, and is a potentially disastrous situation. When the ring is forced against the top of the groove, the pressure which holds the ring tight against the cylinder wall is relieved, and burning gases from the combustion chamber can conceivably shoot past the ring and down the bore, burning away the vital lubricating oil. (See Figure 4.) If the oil burns away, seizure will almost certainly result.

As a general rule, the lighter the ring is, the less likely it is to flutter. Most engines use a 2mm ring, which will begin to flutter when piston acceleration reaches about 66,000 ft./sec.2. “Racing” rings with a thickness of 1mm weigh about half as much as standard rings. Consequently, the 1mm rings won’t begin to flutter until piston acceleration exceeds about 138,000 ft./sec.2. The rpm at which a given engine reaches these rates of acceleration varies according to bore and stroke. The following formula can be used to determine the engine speed at which the rings will flutter:

Rather than use lighter rings to eliminate ring flutter, a few manufacturers use what is known as Dykes ring. The Dykes ring is subject to the effects of piston acceleration as the other rings are, but uses an L-shaped cross section to limit vertical travel. Consequently there is always sufficient gas pressure to hold the ring firmly against the cylinder wall. Take a look at Figures 6 and 7:

Flutter isn’t the only problem associated with piston rings. Two other serious problems, blow-by and oil pumping, can be caused by rings which fail to seal properly. This failure to seal can be caused by several factors, such as a warped, distorted or scored cylinder, worn rings or a worn cylinder.

Blow-by is the more serious of these two problems. Its effects are somewhat similar to the effects of ring flutter. Blow-by occurs when the pressures of combustion are great enough to break the seal provided by the rings. When this happens, the gases force their way into the crankcase. At the least, this condition will cause a loss of power and contamination of the oil in the crankcase. At worst, the gases can burn the lubricating film on the cylinder walls and lead to piston seizure.

Oil pumping is caused by improperly fitted fings. If the rings have excessive side clearance, the piston’s reciprocating motion can create a pumping action which forces oil into the combustion chamber. This will lead to oil fouling of the plugs, excessive oil consumption, and poor combustion. It will also leave big dark rings of soot around the goggles of other motorcyclists who follow you down the road.

In the two-stroke engine the piston rings must operate under the threat of two more difficulties: Carbon and varnish buildup, and snagging in the ports. (Snagging in> the ports is a mechanical term and has nothing to do with sailors on shore leave.) The first problem is largely due to the designers’ fear of the second. In a four-stroke engine, where there are no ports to catch or snag the rings, the rings can be allowed to rotate. This rotation helps keep the cylinder walls scrubbed free of varnish and carbon buildup. However, it is generally not practical to let the rings of a two-stroke rotate freely; if the rings’ ends rotated around and into a port they would very likely spring out and become ensnared. This would normally break the ring, and most tuners agree it’s best not to have fragments of shattered piston rings ricocheting around inside the cylinder.

To prevent the rings from rotating within their grooves, two-strokes nearly always have locating pins in the ring grooves. Keystone (trapezoidal) rings are generally used to provide the scrubbing action which would otherwise be missing.

The locating pin itself can be another trouble spot in the two-stroke engine, especially when the engine is highly tuned and the exhaust port is extremely wide. With the wide exhaust port, much of the piston ring is free to expand outward while the piston is down in the lower half of the cylinder. To prevent the ring from snagging when the piston begins to move upward most engine builders will make the port opening oval and chamfer its edges. While this prevents the ring from snagging, the ring is still slammed back into its groove with tremendous force. As the ring springs out and is shoved back during each crankshaft revolution a tremendous load is placed on the locating pin. If the engine is run extremely hard for extended periods of time, the pin will eventually loosen until the pin works free. When this happens the ring is free to rotate and breakage is imminent.

What modifications can be made to make piston rings work better? Unfortunately the answer is, not many. In stock form piston rings work incredibly well when the magnitude of their task is considered. It is possible to make minor improvements on a manufacturer’s original design, but unless you’re dead serious about performance, the modifications are hardly worth the expense. Consider, for example, the relative merit of fitting a single-ring piston in place of a stock two-ring piston. It might seem initially that such a modification would cut friction in the bore in half, but this is not the case. With a tworing piston the top ring provides most of the seal, so very little gas pressure reaches the second ring. The second ring, then, doesn’t press against the cylinder wall with as much force as the upper ring exerts. Consequently, power losses due to friction from the second ring are minimal. The difference between a single-ring and a two-ring piston will not be apparent below about 7000 rpm.

The same thing is true comparing the advantages of 1mm rings with 2mm rings. Because 1mm rings can’t be used with pistons grooved for 2mm rings, fitting smaller rings means buying a new set of pistons. Once again, the smaller rings will have a slight power advantage over 7000 rpm and are more resistant to fluttering, but below the point at which they begin to flutter, the 2mm rings are more durable and wear better.

For the most part, the best thing you can do for your rings is simply to replace them with good quality units at the first sign of excessive wear. Check compression regularly at 3000 mi. intervals and follow the manufacturer’s recommendations for replacement. Setting proper end gap, for instance is very important when installing new rings. The ends of the rings should not butt up tightly against each other when the piston is slid into the bore. If they do, there is no room for them to expand as they heat up, and broken rings or a scored cylinder wall may result. A small end gap is also needed in the upper compression ring to leak enough gas pressure down to the second ring to force it outward against the cylinder wall. Too much ring gap, of course, will allow excessive blow-by and all the problems that entails.

Ring gap is normally checked by sliding the ring into the cylinder bore and pushing it down into the lower swept area of the bore with an inverted, ringless piston. Using a piston top to move the ring keeps it aligned concentric with the bore. The gap is checked with a blade-type feeler gauge and widened, if necessary, with a small file. In most cases, however, replacement rings will already have plenty of end gap because they are being installed on an engine with some bore wear and slid into a cylinder bore which has been honed. Honing a cylinder bore is always necessary before installing new rings, to rough up the surface of the bore so the new rings can seat properly. Honing is done with springloaded abrasive stones which push outward on the cylinder wall as they are rotated, usually with an electric drill. The rotating stones are drawn up and down in the bore so they leave a cross hatch pattern with the crossed lines running at about a 60° included angle.

In addition to honing, it may be necessary to ream away the upper ridge in a cylinder before installing rings. This ridge is the unworn area at the top of the cylinder bore, just above the uppermost sweep of the top ring. It is important to remove this ridge before installing new rings. The ridge can twist and break rings during installation, and it can also destroy them when the engine is running. If the engine is revved unusually high, crankshaft distortion and rod stretch can slam the rings solidly into the old ridge and break them. Bearing and wrist pin wear, different pistons, or anything else that affects the upper limit of ring travel can have the same effect.

This ridge is normally removed with a ridge reamer, a tool which bolts to the top of the cylinder and contains expanding scraper blades which are turned with a wrench handle or ratchet. The ridge area is scraped until the upper bore diameter is equal to that of the ring-swept area, and then the entire bore is honed.

If the ridge is too pronounced, it usually means there is excessive wear or taper in the bore, in which case the cylinder probably needs to be bored out to the next oversize, with new pistons installed. Cylinder bores tend to wear in a tapered shape because the greatest ring-pressure, sideloads and direction change of the piston occur at the top of the bore, so the top portion wears more than the bottom. The bore also wears in a slight oval, when viewed from the top, again because of thrust loads on the piston. When either the taper or thrust wear are beyond manufacturer’s limits, a boring job (we’ve all had plenty of those) and oversize pistons and rings are called for. Cylinder wear and taper is measured with an inside micrometer or dial indicator, measurements taken at several different heights and radial directions in the bore to get a complete picture of its shape.

On most motorcycle engines,pistonsare slid into the cylinders from the bottom. The cylinder bottoms are normally tapered or chamfered for easy ring installation, and the rings can be compressed enough by hand that they will fit smoothly into the bore. But where there is a sharp edge or in multis, with a number of pistons to contend with at once, a ring compressor may be required. Most ring compressors work like the run-of-the-mill oil filter wrench, with steel bands that tighten around the piston and rings. The edge of the ring compressor is held tightly against the base of the cylinder while the piston is pushed in, preventing the rings from snagging and breaking. The engine is locked in gear during this operation to hold the rod and piston at a convenient working height.

Ring location on the piston is important during installation. On most two-strokes the ring position, is fixed by the locating pins, but on four-strokes the rings should be skewed so the end gaps do not line up, creating a straight path for compression blow-by. Most shop manuals also recommend angling the end gaps away from the thrust sides of the pistons, as these are the areas of greatest side-to-side piston movement and most likely to leak compression through the end gap or wear any initially sharp edges at the ring ends.

Pistons and rings should be oiled before installation, to ease the rings into the bore and to provide lubrication before the reassembled engine builds up oil pressure or, with two-strokes, receives the oil/fuel/air mixture. Engine builders all have different theories about assembly lubrication, some dipping the entire piston in a can of oil and others insisting that only a light film is needed. In any case, excess oil quickly burns off and normal lubrication comes in as soon as the engine is started.

Rings—good rings—are an important part of engine function. Builders of race engines run with unfiltered air intakes have found that compression loss through ring wear is the most significant cause of lost horsepower during the first few hours the engine is raced. The same power-robbing wear takes place in street engines with normal air cleaners, though at a much slower rate. Rings are deceptively simple components but, like valves, their condition can have a tremendous effect on engine performance. Don’t try to squeeze extra miles out of bad rings; you’ll just end up damaging the piston or the cylinder itself. New rings aren’t expensive—and they’re amazingly cheap when you consider the importance of their job.