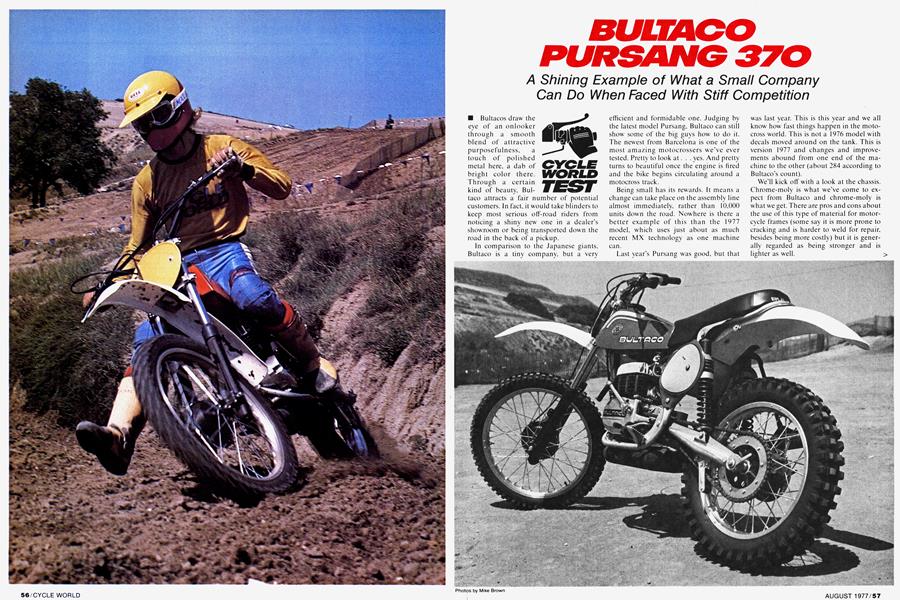

BULTACO PURSANG 370

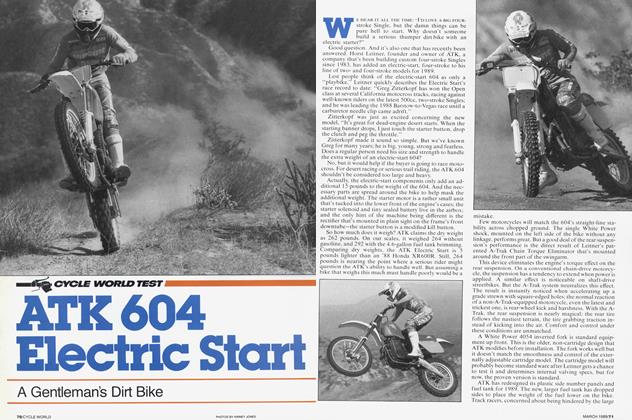

CYCLE WORLD TEST

A Shining Example of What a Small Company Can Do When Faced With Stiff Competition

Bultacos draw the eye of an onlooker through a smooth blend of attractive purposefulness, a touch of polished metal here, a dab of bright color there. Through a certain kind of beauty, Bul-

taco attracts a fair number of potential customers. In fact, it would take blinders to keep most serious off-road riders from noticing a shiny new one in a dealer’s showroom or being transported down the road in the back of a pickup.

In comparison to the Japanese giants, Bultaco is a tiny company, but a very efficient and formidable one. Judging by the latest model Pursang, Bultaco can still show some of the big guys how to do it. The newest from Barcelona is one of the most amazing motocrossers we’ve ever tested. Pretty to look at. . . yes. And pretty turns to beautiful once the engine is fired and the bike begins circulating around a motocross track.

Being small has its rewards. It means a change can take place on the assembly line almost immediately, rather than 10,000 units down the road. Nowhere is there a better example of this than the 1977 model, which uses just about as much recent MX technology as one machine can.

Last year’s Pursang was good, but that was last year. This is this year and we all know how fast things happen in the motocross world. This is not a 1976 model with decals moved around on the tank. This is version 1977 and changes and improvements abound from one end of the machine to the other (about 284 according to Bultaco’s count).

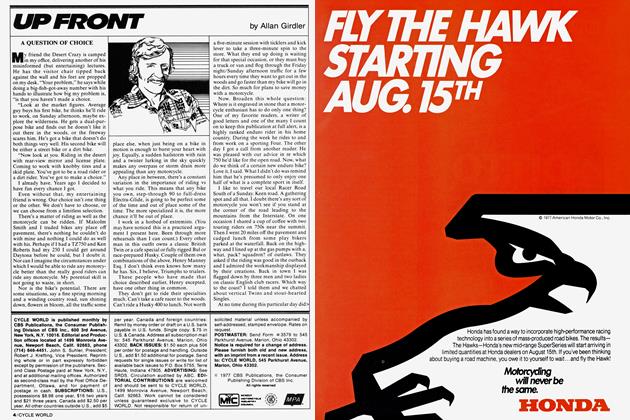

We’ll kick off with a look at the chassis. Chrome-moly is what we've come to expect from Bultaco and chrome-moly is what we get. There are pros and cons about the use of this type of material for motorcycle frames (some say it is more prone to cracking and is harder to weld for repair, besides being more costly) but it is generally regarded as being stronger and is lighter as well.

Changes in the frame for 1977 include special gusseting around the steering head, patterned after factory GP equipment. The idea is to stiffen the downtube assembly and prevent it from flexing if the owner 'should neglect to keep the motor mount bolts or the head steady tight. The engine is located slightly lower in the frame as is the swing arm pivot.

Bultaco doesn’t publish the vital statistics of its front end geometry, but we measured the steering head angle at 29 deg. The Bultaco-manufactured polished aluminum triple clamps are the flat style utilized with Bultaco leading axle forks. All added up, it makes for steering that is positively neutral. The Pursang goes exactly and positively where the rider points it: It’s the best steering off-road motorcycle we’ve ever experienced.

If you’re surprised that we said Bultaco leading-axle forks, you should be. In the past Bultaco front suspension came from Betor, but Betor wasn’t up to supplying enough of the new forks that were needed. So Bultaco solved the problem by going ahead and producing forks for itself. We have to say the resulting product is more than admirable.

The aluminum fork legs have cast-on strengthening bosses and are finished in black. Based on our test machine and bikes we’ve seen in the field, fork seals around the 38-mm stanchion tubes are up to par these days, with no signs of weeping or dribbling. Designed by the Bultaco engineers, the Pursang fork assembly offers damping characteristics that have to be sampled to be truly appreciated.

A professional caliber rider will find the front suspension more than up to the task of handling severe landings, stutter bumps or just about anything else a tough course can dish out.

Even for the rider who isn’t quite up to the skill level of an Aberg or a Pomeroy, the forks do a job that will make him comfortable. At trail speeds the front end soaks up small ripples and such: It’s truly a fork that is able to adapt to any situation.

One might be inclined to call the Bultaco fork a Betor, but just the opposite is true. The design of the Betor-type fork is actually Bultaco’s. Although the rubber boots are Betor, the embossed thumbs up logo shows the forks to be thoroughly Bultaco.

Rearward, Bultaco has taken a radical departure from the norm in the shock department. If you've already spotted the S&Ws in the photos, we reassure you you’re not seeing things. They’re for real and they come standard on the latest Pursangs. Unlike previous S&W shocks, these are rebuildable, and are supported by dual springs. The units are a joint development of S&W, Bultaco and a team of American riders, and are installed on the bike upon its arrival in the U.S.

Mounting position is forward rather than lay-down and it’s easy to notice the ample flat-plate bracing on the tops of the swing arm tubing for extra support. That tubing is 4130 chrome-moly like the frame. An additional tube cross brace is positioned a few inches ahead of the rear tire. The swing arm pivots through both the outside frame rails and the rear motor mount box section piece. Toughness is part of the package. Oil-impregnated bushings with steel inserts are used at the pivot points.

Alloy hubs are in the same category. They’re about the lightest you can find, and they are among the strongest as well. The rear hub design on the 370 makes sense. Placing the steel sprocket on the left and the brake drum on the right allows for employment of a very strong spoke pattern. In addition, heat from the sprocket (touch one after a moto if you don’t believe they get hot) doesn’t transfer to the brake as easily. The brake actuating arm features a grease nipple to allow lubrication at the pivot point. The brake shoes are rod actuated. perhaps not as good as a cable to control rear wheel hop or chatter during hard braking. A polished flat aluminum brake stay attaches to the swing arm about three inches away from the swing arm pivot.

Two other robust features include a chain guard and a chain tensioner for the Joresa 530 chain. The only comment we have here is to wish for a rubbing block of some sort to protect the top of the swing arm where the chain occasionally makes contact. It would also serve to reduce chain wear. The chain on our test machine stretched quite a bit at first and then held its own for the remainder of our time with the bike.

Chain adjustment is accomplished via the very positive snail cam adjusters with teeth that bite into tabs welded to both sides of the swing arm. Stamped-in numbers help count the teeth, but even though the numbers are matched up on both sides there is no insurance that the wheel is aligned. The more serious will eyeball and measure carefully, but the method is basically quick, easy and relatively foolproof.

Like the rear, the front hub saves weight by not using a pressed-in cast-iron liner. Instead, the actual braking surface on which the brake shoes rub is a sprayed-on silicone carbide material. Braking action front and rear is excellent. In spite of the fact that the Pursang uses neither a rear brake cable nor full floating brake design, wheel chatter never presented itself as a problem. Hubs are finished in black, backing plates are polished aluminum.

Standard equipment tires are from Pirelli, but our test machine was equipped with Metzlers which work much better on our hard-packed southern California courses. We recommend the Metzlers highly for use on the Pursang. Wheel rims are the latest ridgeless alloy Akronts, which should last all but the most overzealous riders for quite some timeprovided the steel spoke nipples are watched after and tightened until they’re seated in. Rim locks are standard front and rear.

Suggested list price for the Pursang370 is $1751, the most costly Bultaco except for the limited production Astro 250 Flattracker. But that $1751 buys a bunch.

For example, you get a 60-day unconditional warranty on the entire motorcycle, as long as the bike is used as intended and is not abused, misused or neglected. This means that for a couple of months you’re protected from the little, sometimes expensive nigglies that can crop up after a few racing weekends.

PURSANG 370

SPECIFICATIONS

$1751

POWER TRANSMISSION

DIMENSIONS

FRONT FORKS

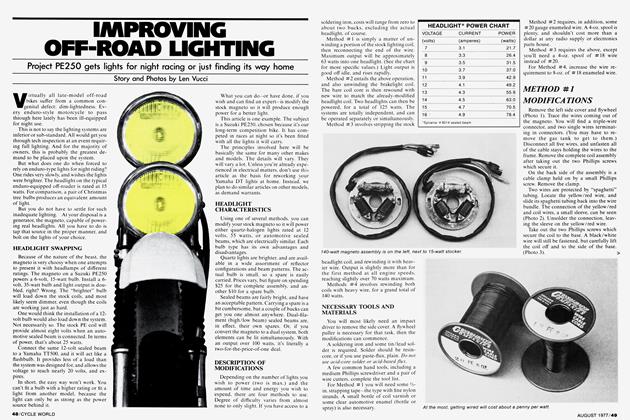

Few will find fault with the Pursang's front end, which works extremely well in virtually any situation. An additional benefit can be derived by gutting the top seal in each leg, reducing "stiction" by half.

Tests performed at Number One Products

REAR SHOCKS

The rear suspension of the Bultaco is commensurate with the front. Although compression damping seems to be un usually high by contemporary stan dards, in point of fact this hind end behaves quite nicely. These new gener ation S&W shocks are also noteworthy in that they are rebuildable.

We’ve done some complaining in the past about the fiberglass or aluminum fenders that have found their way onto Bultacos for so many years. Well, no more, at least not on the 250 and 370 Pursangs and Fronteras. The Pursang’s fenders are flexible white plastic, made in Spain. So is the airbox assembly, which fits snugly under the seat. The airbox has rubbersealed, screw-on plastic side covers which double as number plates.

Inside, a first-class Twin-Air foam filter keeps the impurities from reaching the sensitive innards of the 363-cc engine assembly, which has had a very thorough going over this year. Outwardly it looks about the same, but inside there's been much in the way of shuffling.

Starting with the 5-speed transmission, the shift lever is now made of steel instead of aluminum, and no longer snakes its way around things as it did in the past. A good beginning.

Ratios are ultra close, and virtually every piece in the transmission—from mainshafts to layshafts to gears and shifting dogs—has been beefed up and increased in size. Each gear is 2 mm wider, and their layout on the shafts has been revised to allow quicker and easier shifting. Bultaco still lacks primary kick starting and the kick start lever is still awkwardly placed on the left side of the engine. Nevertheless, this is the best shifting Bultaco to come off any berm since the beginning.

Bultaco claims a 3.5 horsepower increase over last year’s model. Based on seat-of-the-pants feel it seems like even more. A dual Motoplat electronic ignition is used, so there are no points. This just might be the system to be used on every model Bultaco in 1978.

Nearly 2.5 gallons of pre-mixed fuel will go into the fiberglass tank, which this year features more secure rubber mounting. Fuel petcocks are also new and all metal, unlike the plastic leakers of the past. The 36-mm Bing carburetor is manufactured in Spain and finds a home where a squarebodied Amal once nestled. The Bing does a nice job of handling the fuel metering chores, and even has a click-action choke lever for cold starts.

Part of the reason the engine is making new power this year is the newly designed downpipe, which does a decent job of silencing the exhaust note as well. The big Bui seems to have a sound all its own—a throaty, deep-down kind of roar—and never seems harsh to the ear. The other part of the increased power involves the use of new porting. A specially designed back boost port now runs up from low in the cases up the cylinder liner.

To cope with the additional power and to provide a stronger, more reliable engine, major items have been revamped. There is a new' connecting rod, a new piston that is said to be stronger, and a wider, heftier crankshaft assembly. Along with the bigger crankpins there is now a double ball bearing on the right side in place of the old single bearing. On the left is a new slip-fit roller bearing, which will allow the home mechanic to remove it without the use of heat.

To hold cylinder distortion to a minimum during the rigors of long motos, an additional 7 mm of aluminum has been added in the cylinder between the O.D. of the liner and the cylinder fins. As in the past, rubber blocks are fitted in the cylinder fins to dampen mechanical noises emanating from within the engine.

Last year, a lower front engine mount bolt was added and continues on the present models. It seems the bolt helps displace some of the torque and vibration loads to the side frame rails, rather than having the single downtube take it all. This also helps insure everything is more secure in case any of the mount bolts, particularly the cylinder head steady, loosen slightly..

After a couple of lengthy sessions on the latest 370, we were unable to find much at all to complain about. Carburetion was initially on the fat side, but fooling with the needle cured that. We lost the screws out of one of the brackets holding the front number plate in place—our fault for not siliconing the threads. The method of mounting the exhaust pipe doesn’t look as though it comes up to the quality of the rest of the machine, but gave us no problem during the test. The side stand slips into a square bracket in the right side of the bike, but we’d much rather see the bracket on the left.

Plusses? There are many. We like the quality touches such as the use of Allen bolts and self-locking nuts just about everywhere. The fuel tank cap is plastic with perfect edges for easy gripping with gloved hands. However, the fuel tank vent tube which runs out of the cap and down into the center of the steering head is something of a minus. Running that tube elsewhere might be a better idea because of the possibility that fuel could wash the lower steering head bearing clean of lubricant.

continued on page 88

continued from page 60

Starting drill is fairly basic. Open both fuel petcocks and click the choke lever into the down position, stand on the left side of the machine and move the awkward kick start lever into position for a solid kickthrough. One or two kicks was all our test machine ever needed and the engine needs choke for only a few seconds.

Power delivery is exceptional. Warmup laps reveal how well the engine will pull from down low, and we found ourselves purposefully using higher gears than normal just to examine the engine’s power range potential. One can circulate a course quickly without ever buzzing the engine hard, but you can really fly if you let the revs build to where the engine starts to make some horsepower.

Other open-class motocrossers we have tried have more peak horsepower, but it’s the kind that comes on suddenly and is difficult to master for riders with average skill levels. The 370 Pursang can be ridden by a novice more easily than any other machine in its class, especially if we begin to take in the overall handling characteristics of the Spanish beauty.

For those used to other machines, the Bui may seem on the tall side. But this is a necessary evil in these days of two digit suspension travel figures. What may feel even more awkward is the high location of the footpegs, making tall riders have to reach down for the handlebars. The pegs are easy to get used to, but taller riders may want to opt for higher bars. ‘We found, however, that after a while our tallest staff members got used to the seating and standing positions on the 370 and felt more than comfortable. But climb back on another brand of machine, and things will feel strange once again. The high pegs are a good idea for riders who can really lay a machine over on a berm. There is no need to worry about them digging in.

Acclimation will take some time but respect will come quickly to those who twist the throttle hard. The combination of the wide powerband and quiet exhaust can lull the rider into thinking he isn’t going as fast as he is. Fortunately, when the discovery is made, the brakes are more than capable of hauling the machine down to reasonable cornering speeds. And even if one gets in a bit over his head, the incredible steering will get the bike around the corner like it’s on rails.

Bultaco never seems to let up on development and makes the right kind of changes when necessary. It’s nice to know a basically small organization can put its product on the starting line next to the product of any of the giants, and be every bit as competitive and up-to-date.

View Full Issue

View Full Issue