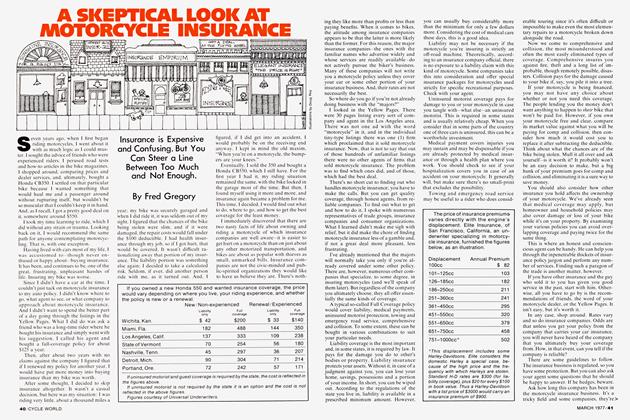

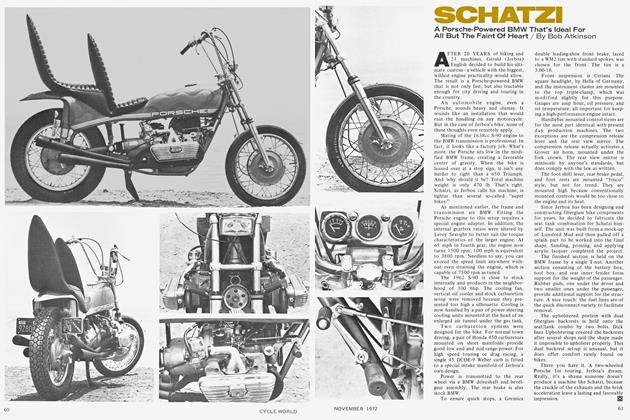

BOLT-ON POWER AND HANDLING FOR THE YAMAHA TT500

Building a Bike That’s Twice as Good as the One You Bought is Easier Than You Think

Bob Atkinson

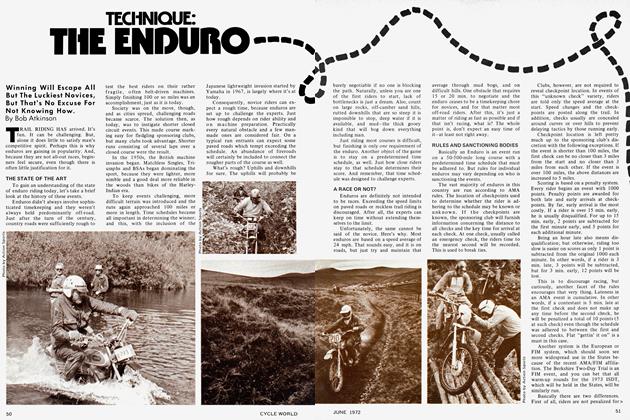

Sometimes motorcycle manufacturers and the general public have different ideas when it comes to the use of a particular machine. Take the Yamaha TT500 for example. Yamaha built the bike for casual dirt riding; for fun, in other words. To Yamaha, fun means not falling off at speed so they built a chassis that favors straight-line stability instead of cornering prowess. To Yamaha, fun means riding when you want to, so they opted for a mild engine that will go a lot of miles between tune-ups.

Fun is also what the public has in mind when they think of the TT500. But fun can mean out-running friends on two-strokes on “casual” Sunday rides. Put another way, most play riders want a machine that w ill out-drag the competition and stay out front long enough to create a suitable impression.

Getting the initial jump on two-strokes requires more horsepower than the TT500 engine has, so we'll deal with this first. Staying out front requires handling improvements so w'e’ll cover some popular chassis modifications as well.

To keep costs down, the benefits of each modification will be discussed so you can pick and choose to suit your own requirements. We’ve also stayed aw'ay from improvements that require welding, grinding, etc. Unbolting stock parts and substituting new ones is all that’s required.

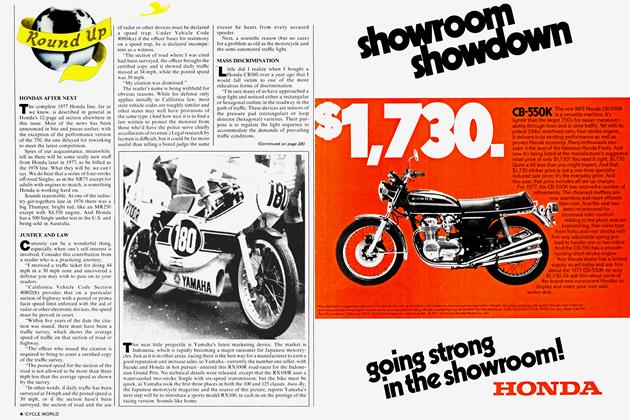

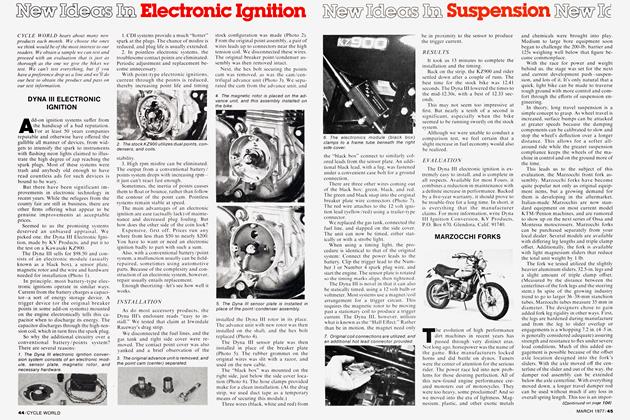

BOLT-ON POWER PRO-TEC CAMSHAFT OILER

A plentiful oil supply to the camshaft , and rocker shaft assemblies is essential on any four-stroke that’s going to be ridden hard. This is especially true on the exhaust valve side of the engine as temperatures here are considerably higher than on the intake side. On the stock engine, oil is delivered to the intake or cool side of the top end first; exactly opposite of what is needed. The result is eventual scoring of the exhaust lobe of the cam. Let this situation go too long and the camshaft will be ruined.

Fortunately, there is a cure and it’s incredibly simple. The top end oiler on the TT500 consists of an external tube that runs from the center cases just behind the oil filter to the rear of the cam cover. Substitute a Pro-tec camshaft oiler which takes oil from the center case location and dumps it into the head through the forward or exhaust rocker shaft cover bolt.

The stock banjo bolt is used at the center case location. The original hole in the cam cover is plugged with a bolt supplied by Pro-tec. The forward rocker shaft cover bolt is discarded and replaced by a Pro-tec item tapped to accept the remaining stock banjo bolt and the Pro-tec oil line.

We think this modification is a must whether you intend to modify the engine or not. Cost of the oiler is $8.95. For further information write to Pro-tec. 8423 Rosemead Blvd., Pico Rivera, Calif. 90660.

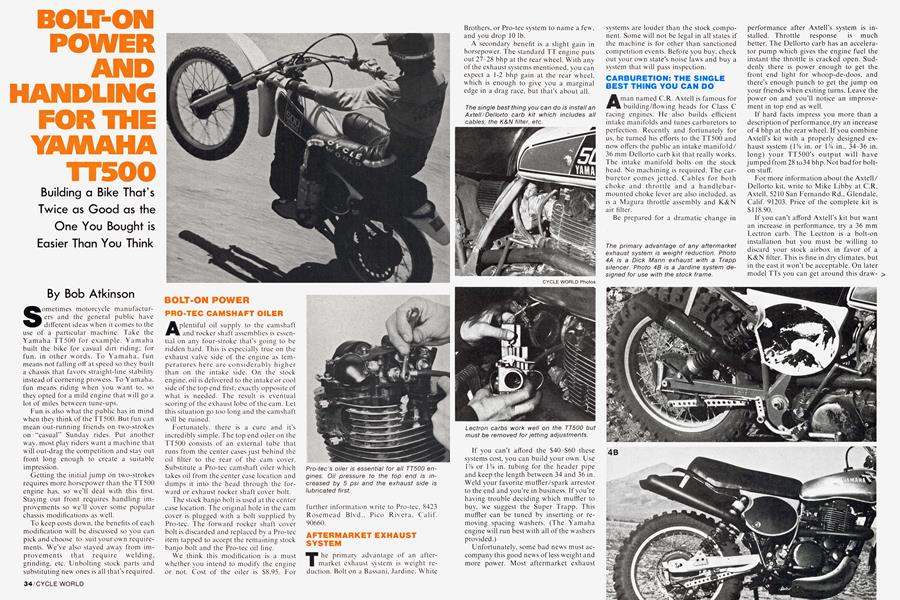

AFTERMARKET EXHAUST SYSTEM

The primary advantage of an aftermarket exhaust system is weight reduction. Bolt on a Bassani, Jardine. White Brothers, or Pro-tec system to name a few, and you drop 10 lb.

A secondary benefit is a slight gain in horsepower. The standard TT engine puts out 27-28 bhp at the rear wheel. With any of the exhaust systems mentioned, you can expect a 1-2 bhp gain at the rear wheel, which is enough to give you a marginal edge in a drag race, but that’s about all.

If you can’t afford the $40-$60 these systems cost, you can build your own. Use VÁ or VÁ in. tubing for the header pipe and keep the length between 34 and 36 in. Weld your favorite muffler/spark arrestor to the end and you’re in business. If you're having trouble deciding which muffler to buy, we suggest the Super Trapp. This muffler can be tuned by inserting or removing spacing washers. (The Yamaha engine will run best with all of the washers provided.)

Unfortunately, some bad news must accompany this good news of less weight and more power. Most aftermarket exhaust

systems are louder than the stock component. Some will not be legal in all states if the machine is for other than sanctioned competition events. Before you buy, check out your own state’s noise laws and buy a system that will pass inspection.

CARBURETION: THE SINGLE BEST THING YOU CAN DO

Aman named C.R. Axtell is famous for . building/flowing heads for Class C racing engines. He also builds efficient intake manifolds and tunes carburetors to perfection. Recently and fortunately for us. he turned his efforts to the TT500 and now offers the public an intake manifold/ 36 mm Dellorto carb kit that really works. The intake manifold bolts on the stock head. No machining is required. The carburetor comes jetted. Cables for both choke and throttle and a handlebarmounted choke lever are also included, as is a Magura throttle assembly and K&N air filter.

Be prepared for a dramatic change in

performance after Axtell’s system is installed. Throttle response is much better. The Dellorto carb has an accelerator pump which gives the engine fuel the instant the throttle is cracked open. Suddenly there is power enough to get the front end light for whoop-de-doos, and there’s enough punch to get the jump on your friends when exiting turns. Leave the power on and you’ll notice an improvement in top end as well.

If hard facts impress you more than a description of performance, try an increase of 4 bhp at the rear wheel. If you combine Axtell’s kit with a properly designed exhaust system (U/s in. or VÁ in., 34-36 in. long) your TT500’s output will have jumped from 28 to34 bhp. Not bad for bolton stuff.

For more information about the Axtell/ Dellorto kit, write to Mike Libby at C.R. Axtell, 5210 San Fernando Rd., Glendale, Calif. 91203. Price of the complete kit is $118.90.

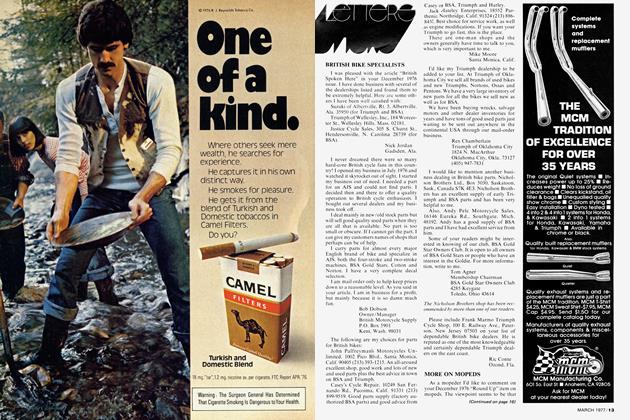

If you can’t afford Axtell’s kit but want an increase in performance, try a 36 mm Lectron carb. The Lectron is a bolt-on installation but you must be willing to discard your stock airbox in favor of a K&N filter. This is fine in dry climates, but in the east it won’t be acceptable. On later model TTs you can get around this draw> back by discarding the stock rubber boot between the airbox and carb and substituting one from a Hodaka 250.

With the Lectron installed and jetted properly, throttle response remains about the same as stock. There is. however, a noticeable power increase in the mid range that tapers off as the engine nears maximum rpm.

The Lectron carburetor sells for $79.50.

It should be available at your local dealer, but if it isn’t, write Sparky Edmonston, 2542 Channel Ave., Riverbank, Calif. 95367.

For even less money, you can adapt a standard 36 mm Mikuni carb. These are available at dealers eveywhere. Results will be similar to those achieved with the Fectron.

PRO-TEC CAM, PISTON AND VALVE SPRINGS

In every group of TT500 owners, there will probably be one who wants a performance edge regardless of the hassle or expense. If we stay within the realm of bolt-on accessories, that edge will come from a piston, cam and valve-spring swap.

The components we selected are manufactured by Pro-tec. The piston is a forged unit that comes with Stellite-coated rings. It increases the compression ratio to 10.5:1 which in turn boosts mid-range power output a great deal (from 50007500 rpm over 30 bhp is produced.) The Magnum 440 camshaft and valve springs let the engine rev another 800 rpm before power falls off, which translates to an additional 2-4 bhp at the rear wheel. Maximum power with this set-up is in the neighborhood of 36-38 bhp. For even more power Pro-tec sells an 11.5:1 piston and a more radical Magnum 480 cam.

To install the piston, cam, and valve springs, a complete set of metric wrenches. a torque wrench, a timing light, and a factory workshop manual (available at Yamaha dealers) are needed.

Installation procedure is as follows:

1. Remove the engine from the frame and clean all external surfaces.

2. Remove the oil delivery pipe at the rear of the cylinder.

3. Remove the six head cover retaining nuts and three bolts. Loosen these in the order specified in the manual.

4. Remove the cover and spark plug.

5. Remove the cam chain tensioner cap.

loosen the tensioner lock nut. and remove the chain tensioner assembly.

6. Remove the cam sprocket securing bolt.

7. Remove the sprocket and chain. It isn't necessary to separate the cam chain but be sure to attach a wire to a chain link to keep the chain from dropping onto the crankcase.

8. Remove the camshaft.

9. Remove the cylinder head hold-down nuts and bolts and remove the head.

10. Remove the cylinder hold-down nuts and bolts and remove the cylinder,.

11. Place a rag under the piston to keep parts from dropping into the crankcase.

12. Remove the piston pin clip, slide the wrist pin out, and remove the piston.

13. Install the Pro-tec piston and rings. Use new wrist pin clips.

14. Compress the valve springs with a suitable tool, remove the spring retainers, and slide out the valves and springs. Reinstall the stock valves with Pro-tec springs. Notice that the Pro-tec system uses an inner and outer spring for each valve.

15. Reassemble the engine by reversing the procedure just described. Be sure to put some grease or heavy oil on the lobes of the new cam to protect them until oil reaches the top end. Be extremely careful to line up all timing marks because it is very easy to be one tooth off on the cam sprocket. Consult the manual for proper torque specifications and valve clearance. Set the valve clearance with the engine cold.

It is not essential, but it is a good idea to remove the stock crankcase breather (it will let some dirt enter the engine) and replace it with a length of 3A-in. tubing extending from the crankcase to the rear fender loop. On the fender end, install a K&N filter, Number CV-3/4. Cost of the filter is $5.95.

Cost of the piston with rings, clips, etc. is $37.95. The 440 camshaft sells for $79.95 and valve springs cost $19.95

BOLT-ON HANDLING

The TT500 does not handle exceptionally well. In 1975 the suspension needed help. Straight-line stability was fair, but the front wheel pushed to the outside in turns. For 1976, Yamaha fitted better forks, better shocks, and changed the steering head angle from the original 30.5 degrees to 30.0 degrees. This improved steering, but did not completely eliminate front end push in turns.

If you have a 1975 model, the first thing to do is purchase a Number One Products fork kit. Number MTF 888. It costs $24.95. For a 1976 model, go to 5 wt. fork oil for trail riding and 10 wt. if you ride fast. See the section on swinging arms for rear suspension modification.

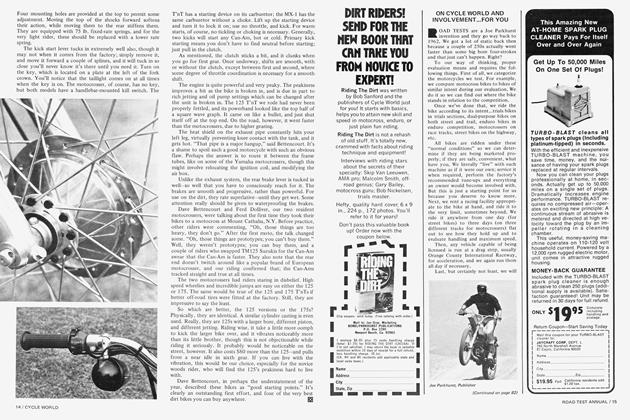

PRO-FAB TRIPLE CLAMPS

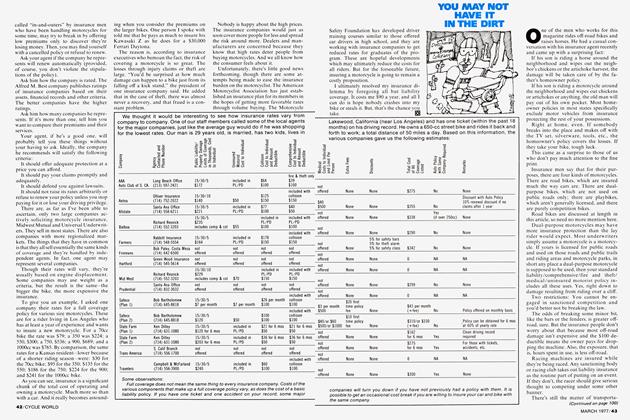

As indicated, the major fault with , T T500 handling is that the front end pushes in turns. There is only one way to correct this and that’s to get more weight on the front wheel. This is done by fitting triple clamps with less offset between steering stem and fork leg. Moving the fork legs 12 mm closer to the steering head allows the front end to bite hard in turns, but does not create a clearance problem between the fork tubes and gas tank. Highspeed stability suffers some, so we don't recommend this change for desert use unless a longer swinging arm is fitted. Triple clamps with this geometry can be bought from Pro-Fab. There are two models, both of which move the tubes 12 mm closer to the steering head. The difference is material and price. The triple clamps pictured separately are cast from A356 aluminum and sell for $93.45. The units used for this test were machined from 2024 T3 aluminum stock and have a list price of $135.

The machined triple clamps are stronger, in theory, and do provide some dazzle, but our choice would be the cast items simply because they work as well and cost less. Either way, write to Pete Wilkins at Pro-Fab, 11581 Anabel Ave., Garden Grove, Calif. 92643.

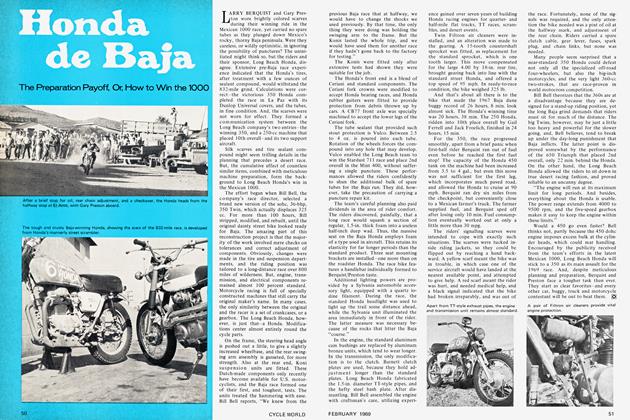

PRO-FAB SWINGING ARMS

The stock Yamaha swinging arm flexes too much for good handling at high speed or anything approaching high speed. It’s also a little short and lets the bike wheelie too much in high traction situations or when climbing hills.

Pro-Fab makes two arms that will cure both problems. Both are an inch longer than stock (at the center of axle adjustment) and both are made from 6061 T6 heat-treated aluminum.

The first arm uses stock length shocks and will yield 6-7 in. of travel, depending on the stroke available in your shock. The second arm is similar but has the shock mounts relocated 1 in. to the rear. This arm uses 1 in. longer shocks and yields approximately 8 in. of travel. Again, the exact travel depends on the stroke available in your shock.

Handling is vastly improved with both the triple clamps and aluminum swinging arm installed. The bike goes where you point it, slides much better than a stocker and will not wheelie when you don’t want it to. When you get into a turn too hot, the bike can be forced around. If you can’t afford an accessory frame, this is definitely the way to go. Price of either Pro-Fab swinging arm is $127.50

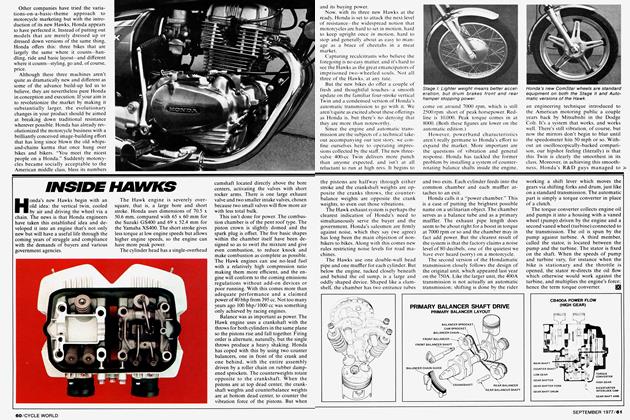

AFTERMARKET FRAMES

With the Yamaha’s stock frame you can get close to optimum handling in every area but weight. Weight is not a problem at low speed, or when the ground is fairly smooth. It is a problem if you try to go fast or if your favorite riding area is full of cross-grain ruts, whoop-de-doos, and washouts. That is not to say you will crash harder on a heavy bike, but you will get tired a lot faster which may cause you to crash more often.

Most aftermarket frames will save 1012 lb. over stock. Add to this the 10 lb. already saved in the exhaust system and the bike will weigh approximately 262 lb. This is three lb. less than a Yamaha IT400. Still heavy, but not unmanageable.

If you like a bike with a light front end that steers very quickly, and if you want to > keep the price down, try Kenny Roberts’ new cow-trailing frame. It’s made from mild steel (Kenny claims the use of chrome-moly isn't as necessary for strength as some people think) and is wirewelded. You can buy the frame with swinging arm for approximately $495. It is designed for use with the stock wheels, forks, triple clamps, seat, gas tank, fenders, etc. It comes in black.

We built one of these bikes and are very satisfied with it. All the stock components fit without bending or filing. It feels 20 lb. lighter than it is and is a lot of fun to ride. We used a pair of S&W LL525-9 shocks (which Kenny recommends) and found the ride to be soft, controllable and just right for cow trailing or enduros. If purchased separately, the S&Ws go for $83.60 a pair, including springs.

If you favor the quick steering of a woods bike, but prefer chrome-moly, try a Dick Mann frame. It is similar to Kenny’s in that it is designed to be used with stock Yamaha components right down to the triple clamps. Everything bolts right on. We know. We watched Brian Fabre of Number One Products build his. Brian’s bike has a short swinging arm but Mann offers a longer one for desert use. An exhaust pipe and Fox shocks with springs can be ordered with the basic frame kit.

The first thing we noticed when we rode this bike was its surprisingly good traction. Powering out of tight turns or getting the jump in a drag race is easy, even with the modified engine. Steering is also good, especially with a 3.00-3.20 Barum front tire. Suprisingly enough, the Dick Mann machine doesn’t wheelie much easier than a stocker.

The optional Fox shocks work well if you ride hard. For enduros or trail riding something with softer damping is in order. Brian has had excellent results with a set of Number One Products’ FP shocks with the medium damping curve. These are freon bag shocks like the S&W, they are rebuildable, and sell for $69.95 a pair. Springs cost $24.95. If you want to minimize the expenditure, use your stock Kayaba shocks.

The Dick Mann frame kit can be purchased at most dealers and the price is $595. The exhaust pipe costs $29 and should be used with a Trapp muffler/ spark arrestor. Fox shocks can be shipped with the frame for $120. For additional information, write to Dick Mann Specialties, 904 Wright Ave., Unit 34, Richmond, Calif. 94801 or phone (415) 2346556.

If you like desert racing or want to build a Baja racer replica, a C&J Racing frame is the way to go. The company has had a lot of experience with the four-stroke Honda and now builds a version for the Yamaha TT500. C&J builds several versions, which can be confusing. The basic model uses the stock components, right down to the fenders and airbox. There are other versions, even two with the oil tank behind the engine rather than in the top frame tube (the better for a low center of gravity). Thing is, C&J will sell the bolt-together frame or a frame requiring some additional work or they’ll build a frame to your design . . . but the customer must carefully specify which model when the order is placed.

Both the C&J frame with stock oil tank location and the frame for a remote tank are set up to use 14’/4-14!/2-in. shocks. Rear wheel travel is approximately IVi in. If more rear wheel travel is desired, another set-up is available which uses 16V2 in. shocks and yields 9'/2 in. of travel. They will build anything you want: The only limiting factor is the thickness of your wallet.

All C&J frames are made from 4130 chrome-moly. Oil-in-frame models go for $595. Remote tank applications cost $635. C&J’s address is 3873 S. Main, Santa Ana, Calif. 92707.

One final suggestion. If you intend to race a C&J Yamaha cross country, it’s hard to beat Works Performance Shocks. Like C&J, they custom build for specific applications. Write to Gil at 20970 Knapp St., Chatsworth, Calif. 91311. [oj

View Full Issue

View Full Issue