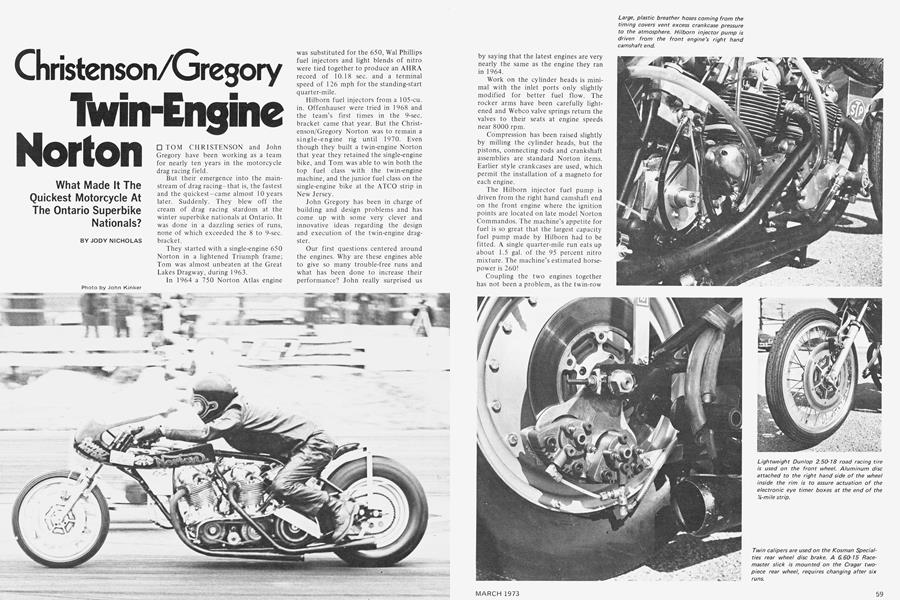

Christenson/Gregory Twin-Engine Norton

What Made It The Quickest Motorcycle At The Ontario Superbike Nationals?

JODY NICHOLAS

TOM CHRISTENSON and John Gregory have been working as a team for nearly ten years in the motorcycle drag racing field.

But their emergence into the mainstream of drag racing—that is, the fastest and the quickest—came almost 10 years later. Suddenly. They blew off the cream of drag racing stardom at the winter superbike nationals at Ontario. It was done in a dazzling series of runs, none of which exceeded the 8 to 9-sec. bracket.

They started with a single-engine 650 Norton in a lightened Triumph frame; Tom was almost unbeaten at the Great Lakes Dragway, during 1963.

In 1964 a 750 Norton Atlas engine was substituted for the 650, Wal Phillips fuel injectors and light blends of nitro were tied together to produce an AHRA record of 10.18 sec. and a terminal speed of 126 mph for the standing-start quarter-mile.

Hilborn fuel injectors from a 105-cu. in. Offenhauser were tried in 1968 and the team’s first times in the 9-sec. bracket came that year. But the Christenson/Gregory Norton was to remain a single-engine rig until 1970. Even though they built a twin-engine Norton that year they retained the single-engine bike, and Tom was able to win both the top fuel class with the twin-engine machine, and the junior fuel class on the single-engine bike at the ATCO strip in New Jersey.

John Gregory has been in charge of building and design problems and has come up with some very clever and innovative ideas regarding the design and execution of the twin-engine dragster.

Our first questions centered around the engines. Why are these engines able to give so many trouble-free runs and what has been done to increase their performance? John really surprised us by saying that the latest engines are very nearly the same as the engine they ran in 1964.

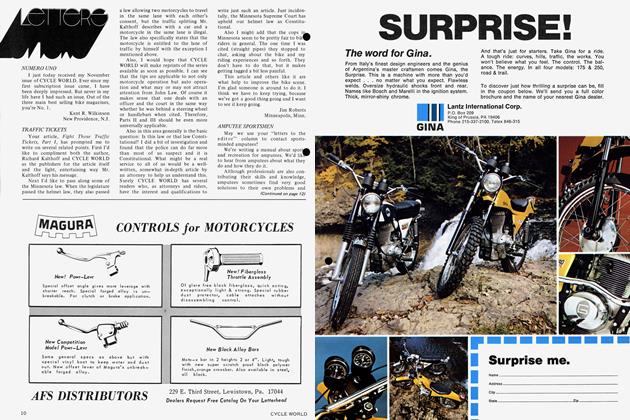

Work on the cylinder heads is minimal with the inlet ports only slightly modified for better fuel flow. The rocker arms have been carefully lightened and Webco valve springs return the valves to their seats at engine speeds near 8000 rpm.

Compression has been raised slightly by milling the cylinder heads, but the pistons, connecting rods and crankshaft assemblies are standard Norton items. Earlier style crankcases are used, which permit the installation of a magneto for each engine.

The Hilborn injector fuel pump is driven from the right hand camshaft end on the front engine where the ignition points are located on late model Norton Commandos. The machine’s appetite for fuel is so great that the largest capacity fuel pump made by Hilborn had to be fitted. A single quarter-mile run eats up about 1.5 gal. of the 95 percent nitro mixture. The machine’s estimated horsepower is 260!

Coupling the two engines together has not been a problem, as the twin-row primary chain between the engines and from the rear engine to the clutch have proven unfailingly reliable.

An average engine life at top performance is around 35 runs, but as many as 50 runs have been made without engine failure. John attributes much of this success to Kendall Nitro 70 lubricating oil which is changed after every run and to the addition of teflon oil seals inside the engine. Not a single engine failure has been experienced during an actual competition run, but a few engines have been lost during the starting drill by opening the throttle too wide at too low an engine rpm, causing the engine to “hydraulic” from too much fuel being pumped into the combustion chambers.

An interesting design feature is the “slider” clutch, which has been used on automobiles for some time. At the start of a drag race, the engine is revved and the hydraulically operated clutch is released. However, this clutch, which has adjustable weights to vary the point at which it becomes “solid,” slips right after it is engaged to permit the rear wheel to get up to a certain speed before the weights cause it to lock. This speed can be varied by changing the number of weights. The unit weighs 17 lb. and hasn’t given any trouble in two years.

An interesting two-speed planetary gearbox was designed and built by John Gregory which uses gears from a Rambler automobile. Although it has proven reliable until just recently, there has been some trouble with the unit slipping out of high gear near the end of the drag strip. In fact, Tom’s record run of 8.52 sec. at 165 mph was made with the bike in neutral: it jumped out of gear just before the timing traps!

Frame design is very similar to most twin-engine drag bikes running in America today and is constructed of 0.065 in. wall thickness 4130 mild steel tubing. Weight of the bare frame is 21 lb. and the wheelbase is a nominal 73 in. An unusual design feature is that the frame is not perfectly true in the fore/aft plane. Rather, it is offset slightly to counteract the torque of the two engines pulling on the left hand side so that the machine will steer straight while accelerating.

Tom says that he tries to be in the left hand portion of the lane he’s running in at the end of the strip because the machine has a slight tendency to pull to the right when the power is shut off. However, no handling problems have been experienced.

To get the power to the ground a 6.60-15 M/H slick tire is mounted on a Cragar wheel which has sprocket and disc brake assemblies manufactured by Kosman Specialties in San Francisco. Average tire life is about six full-throttle runs. A disc brake is also used on the front wheel which sports a 2.50-18 Dunlop road racing tire.

Total weight of the twin-engine Norton is close to 410 lb., but total weight doesn’t concern the team. It’s where the weight is placed that makes so much difference in getting traction off the line and then being able to steer the machine down the drag strip.

And so with the help of Greg Wright, who acts as the mechanic at drag events, Tom Christenson and John Gregory have climaxed the 1972 drag racing season with the quickest accelerating motorcycle ever, in spite of the fact that their single-gear twin-engine Norton turned a top speed of 180 mph at the U.S. 30 Drag Strip in Gary, Ind., recently. In drag racing it’s the man who gets through the timing lights first, not necessarily the one who’s going the fastest.