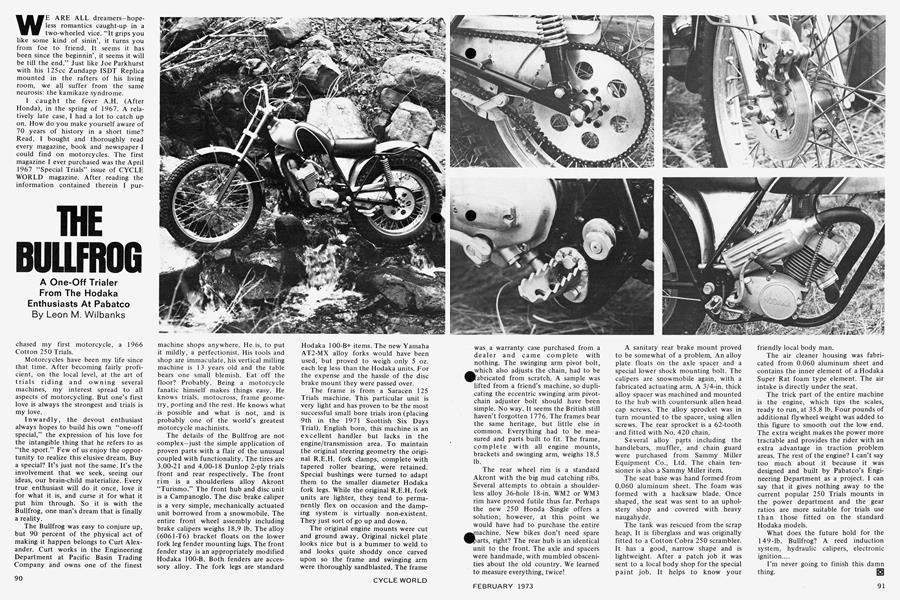

THE BULLFROG

A One-Off Trialer From The Hodaka Enthusiasts At Pabatco

Leon M. Wilbanks

WE ARE ALL dreamers—hopeless romantics caught-up in a two-wheeled vice. “It grips you like some kind of sinin’, it turns you from foe to friend. It seems it has been since the beginnin,' it seems it will be till the end.” Just like Joe Parkhurst with his 125cc Zundapp ISDT Replica mounted in the rafters of his living room, we all suffer from the same neurosis: the kamikaze syndrome.

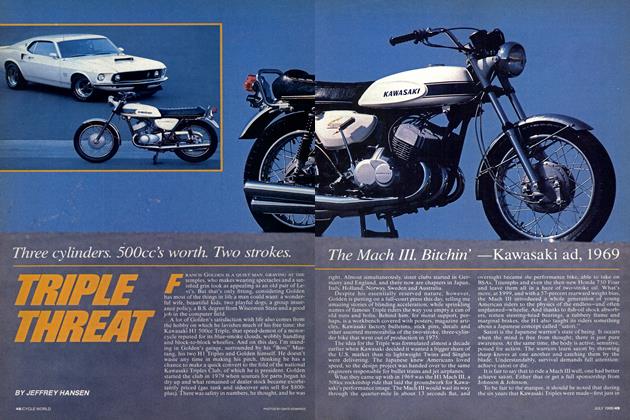

I caught the fever A.H. (After Honda), in the spring of 1967. A relatively late case, I had a lot to catch up on. How do you make yourself aware of 70 years of history in a short time? Read. I bought and thoroughly read every magazine, book and newspaper I could find on motorcycles. The first magazine I ever purchased was the April 1967 “Special Trials” issue of CYCLE WORLD magazine. After reading the information contained therein I purchased my first motorcycle, a 1966 Cotton 250 Trials.

Motorcycles have been my life since that time. After becoming fairly proficient, on the local level, at the art of trials riding and owning several machines, my interest spread to all aspects of motorcycling. But one’s first love is always the strongest and trials is my love.

Inwardly, the devout enthusiast always hopes to build his own “one-off special,” the expression of his love for the intangible thing that he refers to as “the sport.” Few of us enjoy the opportunity to realize this elusive dream. Buy a special? It’s just not the same. It’s the involvement that we seek, seeing our ideas, our brain-child materialize. Every true enthusiast will do it once, love it for what it is, and curse it for what it put him through. So it is with the Bullfrog, one man’s dream that is finally a reality.

The Bullfrog was easy to conjure up, but 90 percent of the physical act of making it happen belongs to Curt Alexander. Curt works in the Engineering Department at Pacific Basin Trading Company and owns one of the finest machine shops anywhere. He is, to put it mildly, a perfectionist. His tools and shop are immaculate, his vertical milling machine is 13 years old and the table bears one small blemish. Eat off the floor? Probably. Being a motorcycle fanatic himself makes things easy. He knows trials, motocross, frame geometry, porting and the rest. He knows what is possible and what is not, and is probably one of the world’s greatest motorcycle machinists.

The details of the Bullfrog are not complex—just the simple application of proven parts with a flair of the unusual coupled with functionality. The tires are 3.00-21 and 4.00-18 Dunlop 2-ply trials front and rear respectively. The front rim is a shoulderless alloy Akront “Turismo.” The front hub and disc unit is a Campanoglo. The disc brake caliper is a very simple, mechanically actuated unit borrowed from a snowmobile. The entire front wheel assembly including brake calipers weighs 18.9 lb. The alloy (6061-T6) bracket floats on the lower fork leg fender mounting lugs. The front fender stay is an appropriately modified Hodaka 100-B. Both fenders are accessory alloy. The fork legs are standard Hodaka 100-B+ items. The new Yamaha AT2-MX alloy forks would have been used, but proved to weigh only 5 oz. each leg less than the Hodaka units. For the expense and the hassle of the disc brake mount they were passed over.

The frame is from a Saracen 125 Trials machine. This particular unit is very light and has proven to be the most successful small bore trials iron (placing 9th in the 1971 Scottish Six Days Trial). English born, this machine is an excellent handler but lacks in the engine/transmission area. To maintain the original steering geometry the original R.E.H. fork clamps, complete with tapered roller bearing, were retained. Special bushings were turned to adapt them to the smaller diameter Hodaka fork legs. While the original R.E.H. fork units are lighter, they tend to permanently flex on occasion and the damping system is virtually non-existent. They just sort of go up and down.

The original engine mounts were cut and ground away. Original nickel plate looks nice but is a bummer to weld to and looks quite shoddy once carved upon so the frame and swinging arm were thoroughly sandblasted. The frame was a warranty case purchased from a dealer and came complete with nothing. The swinging arm pivot bolt, wvhich also adjusts the chain, had to be fabricated from scratch. A sample was lifted from a friend’s machine, so duplicating the eccentric swinging arm pivotchain adjuster bolt should have been simple. No way. It seems the British still haven’t forgotten 1776. The frames bear the same heritage, but little else in common. Everything had to be measured and parts built to fit. The frame, complete with all engine mounts, brackets and swinging arm, weighs 18.5 lb.

The rear wheel rim is a standard Akront with the big mud catching ribs. Several attempts to obtain a shoulderless alloy 36-hole 18-in. WM2 or WM3 rim have proved futile thus far. Perhaps the new 250 Honda Single offers a solution; however, at this point we would have had to purchase the entire unachine. New bikes don’t need spare farts, right? The rear hub is an identical unit to the front. The axle and spacers were handmade, with mumbled obscenities about the old country. We learned to measure everything, twice!

A sanitary rear brake mount proved to be somewhat of a problem. An alloy plate floats on the axle spacer and a special lower shock mounting bolt. The calipers are snowmobile again, with a fabricated actuating arm. A 3/4-in. thick alloy spacer was machined and mounted to the hub with countersunk alien head cap screws. The alloy sprocket was in turn mounted to the spacer, using alien screws. The rear sprocket is a 62-tooth and fitted with No. 420 chain.

Several alloy parts including the handlebars, muffler, and chain guard were purchased from Sammy Miller Equipment Co., Ltd. The chain tensioner is also a Sammy Miller item.

The seat base was hand formed from 0.060 aluminum sheet. The foam was formed with a hacksaw blade. Once shaped, the seat was sent to an upholstery shop and covered with heavy naugahyde.

The tank was rescued from the scrap heap. It is fiberglass and was originally fitted to a Cotton Cobra 250 scrambler. It has a good, narrow shape and is lightweight. After a patch job it was sent to a local body shop for the special paint job. It helps to know your friendly local body man.

The air cleaner housing was fabricated from 0.060 aluminum sheet and contains the inner element of a Hodaka Super Rat foam type element. The air intake is directly under the seat.

The trick part of the entire machine is the engine, which tips the scales, ready to run, at 35.8 lb. Four pounds of additional flywheel weight was added to this figure to smooth out the low end. The extra weight makes the power more tractable and provides the rider with an extra advantage in traction problem areas. The rest of the engine? I can’t say too much about it because it was designed and built by Pabatco’s Engineering Department as a project. I can say that it gives nothing away to the current popular 250 Trials mounts in the power department and the gear ratios are more suitable for trials use than those fitted on the standard Hodaka models.

What does the future hold for the 149-lb. Bullfrog? A reed induction system, hydraulic calipers, electronic ignition....

I’m never going to finish this damn thing.

View Full Issue

View Full Issue