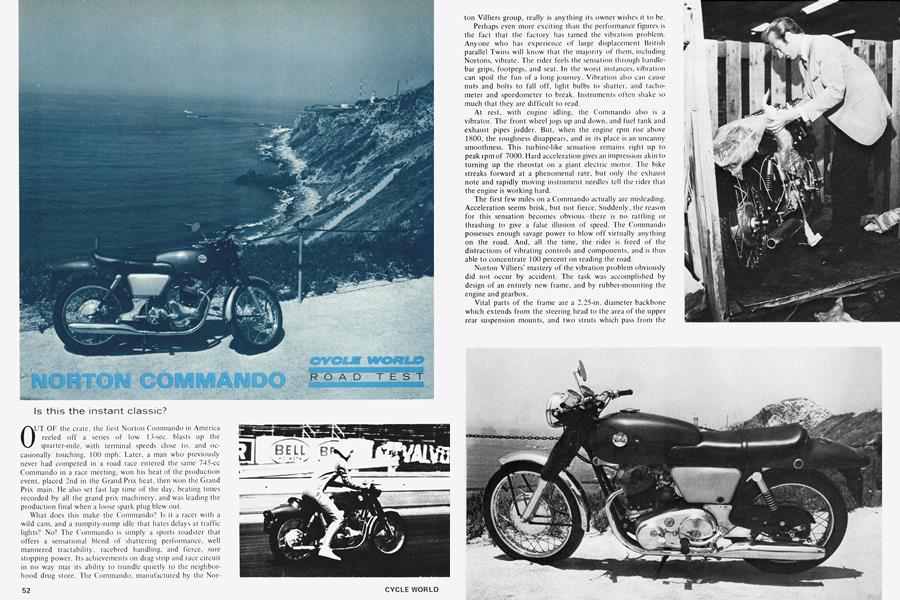

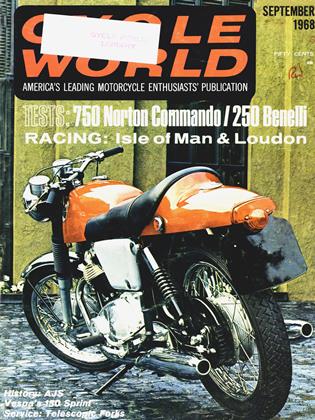

NORTON COMMANDO

CYCLE WORLD ROAD TEST

Is this the instant classic?

OUT OF the crate, the first Norton Commando in America reeled off a series of low 13-sec. blasts up the quarter-mile, with terminal speeds close to, and occasionally touching, 100 mph. Later, a man who previously never had competed in a road race entered the same 745-cc Commando in a race meeting, won his heat of the production event, placed 2nd in the Grand Prix heat, then won the Grand Prix main. He also set fast lap time of the day, beating times recorded by all the grand prix machinery, and was leading the production final when a loose spark plug blew out.

What does this make the Commando? Is it a racer with a wild cam, and a rumpity-rump idle that hates delays at traffic lights? No! The Commando is simply a sports roadster that offers a sensational blend of shattering performance, well mannered tractability, racebred handling, and fierce, sure stopping power. Its achievements on drag strip and race circuit in no way mar its ability to trundle quietly to the neighborhood drug store. The Commando, manufactured by the Norton Villiers group, really is anything its owner wishes it to be.

Perhaps even more exciting than the performance figures is the fact that the factory has tamed the vibration problem. Anyone who has experience of large displacement British parallel Twins will know that the majority of them, including Nortons, vibrate. The rider feels the sensation through handlebar grips, footpegs, and seat. In the worst instances, vibration can spoil the fun of a long journey. Vibration also can cause nuts and bolts to fall off, light bulbs to shatter, and tachometer and speedometer to break. Instruments often shake so much that they are difficult to read.

At rest, with engine idling, the Commando also is a vibrator. The front wheel jogs up and down, and fuel tank and exhaust pipes judder. But, when the engine rpm rise above 1800, the roughness disappears, and in its place is an uncanny smoothness. This turbine-like sensation remains right up to peak rpm of 7000. Hard acceleration gives an impression akin to turning up the rheostat on a giant electric motor. The bike streaks forward at a phenomenal rate, but only the exhaust note and rapidly moving instrument needles tell the rider that the engine is working hard.

The first few miles on a Commando actually are misleading. Acceleration seems brisk, but not fierce. Suddenly, the reason for this sensation becomes obvious there is no rattling or thrashing to give a false illusion of speed. The Commando possesses enough savage power to blow off virtually anything on the road. And, all the time, the rider is freed of the distractions of vibrating controls and components, and is thus able to concentrate 100 percent on reading the road.

Norton Villiers” mastery of the vibration problem obviously did not occur by accident. The task was accomplished by design of an entirely new frame, and by rubber-mounting the engine and gearbox.

Vital parts of the frame are a 2.25-in. diameter backbone which extends from the steering head to the area of the upper rear suspension mounts, and two struts which pass from the center of the backbone to the rear legs of the engine loops. This section forms a triangulated structure, and provides the greater part of the frame’s resistance to torsional stresses. The remaining frame tubes the duplex engine loops, and the rear mudguard support are not stressed, and serve only to locate components. Because so few of the frame tubes are stressed, Norton Villiers has been able to hold total frame weight to 24 lb. The factory says this is approximately 30 percent lighter and stronger than anything it previously has made.

Frame configuration is fairly orthodox. However, the method used to mount the swinging arm pivot on the plates which link the separate engine and gearbox rather than directly to the frame shows a completely new line of engineering thought. Engine and transmission are supported in the frame by large rubber bushes at the front of the crankcase, behind the gearbox, and at the cylinder head. Thus the entire unit, including the rear fork pivot, is suspended in the frame. Vibration which emanates from the crankshaft is absorbed before it can affect rider or machine. Detroit engineers long have employed rubber engine-to-chassis-to-bodymountings to produce the sought-after boulevard ride of Lincoln and Cadillac. Norton Villiers has joined the club.

The factory also has taken a look at every other feature a high performance sports bike should possess. The engine behind those quick quarter-mile figures is the ohv Atlas unit, already used on Atlas roadster and Ranger street scrambler machines, and noted for reliability and power. For the Commando, several modifications have been made. Compression ratio has been raised to 8.9:1, and primary drive has been strengthened by adopting a triplex chain, in place of the single-row chain previously employed. A cast alloy primary casing replaces the stamped steel unit found on Atlases. Service has been simplified by the use of only one fixing bolt for the casing. Previous engines employed about a dozen bolts around the casing perimeter. A plug in the casing covers an inspection hole that permits ignition timing to be checked with a strobe light.

The engine also features parallel induction ports, and widely spaced exhaust ports, to provide maximum breathing efficiency. A built-up forged steel crankshaft, with central iron flywheel, is supported on plain bearings. Two-piece connecting rods and alloy pistons operate inside a cast iron cylinder block. Valve operation is by forged steel rockers, large diameter tappets, alloy pushrods, and a chain driven camshaft.

Laycock de Normanville, a firm which specializes in automobile transmissions, designed the new four-plate, diaphragm spring type clutch one of the smoothest, lightest units ever fitted to a large displacement motorcycle. Two-finger pressure is sufficient for gear changes, even though the clutch exerts nearly double the pressure of the conventional unit it replaces.

Carburetion also has been subject to change. Amal Concentrics supersede the Monoblocs used on Atlases. They are fed by a large air cleaner. Because of the engine’s forward tilt, downward curving induction stubs are employed, to avoid an excessively high carburetor location.

A crankshaft driven alternator, and 12-V battery supply power for ignition. The bike also is fitted with a capacitor, a little device that stores energy and enables the engine to be started with or without the battery that means no problems should the battery be exhausted. Lights also can be operated without the battery, provided the engine is running.

Performance and flexibility are the Commando’s specialties. Usable power begins at 2000 rpm, and frantic gear changing is not necessary in order to get places fast. Only one fault marred the Commando’s roadability. Center and sidestgnds are set so low that the left side where the sidestand is attached continually scrapes the ground on all corners where little more than average lean is required. With the pillion seat occupied, the stands hit the pavement so quickly that any attempt at fast cornering is downright dangerous. Even the right side, where only the center stand projects, easily can be made to scrape the ground.

In view of the care which has been taken with the remainder of the machine, it seems odd that Norton Villiers has allowed this very obvious and potentially dangerous fault to go farther than prototype Commandos. Anyone who intends to make full use of the bike’s considerable cornering abilities, may wish to remove, or find a new location for, the sidestand, and perhaps the center stand.

Handling itself is superbly stable in all kinds of conditions. The front fork is the famous Norton Roadholder pattern, with two-way damping and single-rate springs. This fork has earned what is virtually a worldwide reputation for its excellent handling qualities. Rear suspension is by Girling hydraulic spring/damper units, with springs adjustable to three different positions. Cornering is not light, yet the Commando is one of the best handling heavyweights available. Its charm lies in its absolute steadiness, and refusal to veer from the chosen line. This breeds a relationship of total confidence between rider and machine.

Gear change action is typically Norton crisp, satisfyingly “solid,” with swift and short pedal movements. There are no false neutrals, and first gear is engaged from rest with no clunks or grating.

In the quest for greater speed, the factory has not forgotten to provide adequate brakes. On the front wheel is a new twin leading shoe unit of 8-in. diameter, that works quietly and powerfully, with light lever pressures. The rear brake is a standard Norton component, effective and strong. The front unit has a scoop to draw in cooling air, but the scoop is intended mainly for racing. For road use, it is blanked off by an easily removable metal cover plate.

A fairly short, straight handlebar was fitted to the test machine, and proved ideal for fast riding. However, a high rise American pattern bar also is available, and will be fitted to a great number of Commandos sold in the U.S. Rider comfort is provided for by a generous, well padded seat, which is roomy enough for two people who spend long hours in the saddle. Footpegs are located by large alloy castings attached to the frame, a method that helps prevent vibration from reaching the feet.

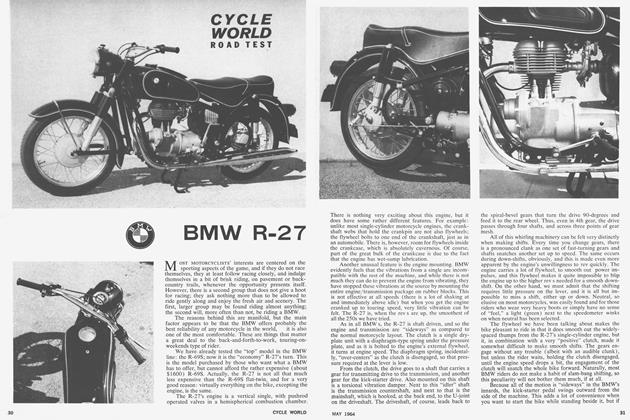

In appearance, the Commando is truly a stunning motorcycle. A fiberglass fuel tank, with quick action flip-up filler cap, and rear mudguard unit, also formed of fiberglass, take much of the credit for the smart looks. During the test period, the Commando attracted considerable attention from other motorcyclists, and the most frequent question was: “Where did the fiberglass come from?” They were impressed when told that it was standard factory equipment!

The front mudguard is of alloy. Large 19-in. wheels carry a 3-in. section tire in front, and a 3.50-in. Avon Grand Prix at the rear. This cover is formed in the same mold as Avon racing tires, though its rubber content is less “sticky,” and therefore longer wearing, than the racing versions. Oil tank filler cap and battery are housed beneath the seat, which is quickly detached by undoing two retaining knobsone at each side. An exterior plastic window enables instant oil level checks to be made.

Not content with offering power, smoothness, handling, brakes and good looks all in one machine, Norton Villiers has decided to offer enthusiasts a true mindblower in the form of three high performance conversion kits, the “wildest” of which provides a claimed top speed of 137 mph! The factory says this kit, the Stage III, powers the bike to 100 mph in a mere 1 1.5 sec. This stage puts the engine into full racing tune, and is not intended for street use. Stages I and II are for brave road riders who like to show drivers of 400-cu. in. engined automobiles what acceleration is really about. The first kit offers a claimed 10 percent power boost, 120 mph top speed, and a 0 to 100 time of 13.75 sec. Stage II, says the factory, gives 16 percent additional power, 130 mph, and acceleration to the “ton” in just 12.75 sec. A fourth kit, which customizes appearance only, includes clip-on handlebars and rearset footpegs (to make the rider feel like Mike Hailwood!), alloy wheel rims, colored fork and rear suspension gaiters, and other items.

Opposition during the bike’s road racing debut was not exactly championship material. Its achievements there were still magnificent, considering that it remained in as-you-buy-it street trim, apart from removal of side and center stands, a change of plugs, and the addition of number plates. To prove that these results were not obtained by luck, the bike was given a second road race outing, among much stiffer opposition. It easily won the production event, and placed 3rd in the Grand Prix event, behind two genuine racing machines equipped with fairings.

During drag strip tests a staff member of the West Coast distributor actually recorded a staggering quarter-mile time of 13.13 sec., with a terminal speed of 100.44 mph. The best time set on the CYCLE WORLD test day was 13.47 sec., and the bike proved capable of setting a whole series of times in the low 13s, with no sign of distress from the sorely punished clutch.. The Commando’s performances actually make it the second fastest machine CYCLE WORLD ever has tested. Only the Dunstall Norton, produced by racing specialist and customizer Paul Dunstall, has bettered the Commando’s times in the quarter mile. And, even the Dunstall machine employed a modified version of the Norton 750 engine.

Even in basic form, the Commando embodies an extravaganza of delectable qualities that leave riders talking in a lengthy series of superlatives. Undoubtedly, never before has a motorcycle offered such smoothness combined with such power. Certain fabled machines, such as the Vincent and the Ariel Square Four, have earned places high in the list of all-time great motorcycles. No one should be surprised if the Commando acquires a reputation that will allow it to join that select band.

NORTON COMMANDO

$1457